CFMoto motorcycle CF650NK. Service Manual - part 26

9-36 CRANKSHAFT/TRANSMISSION

Transmission

Transmission Shaft Disassembly

●

Remove the transmission assy (see Transmission

Assy Removal).

●

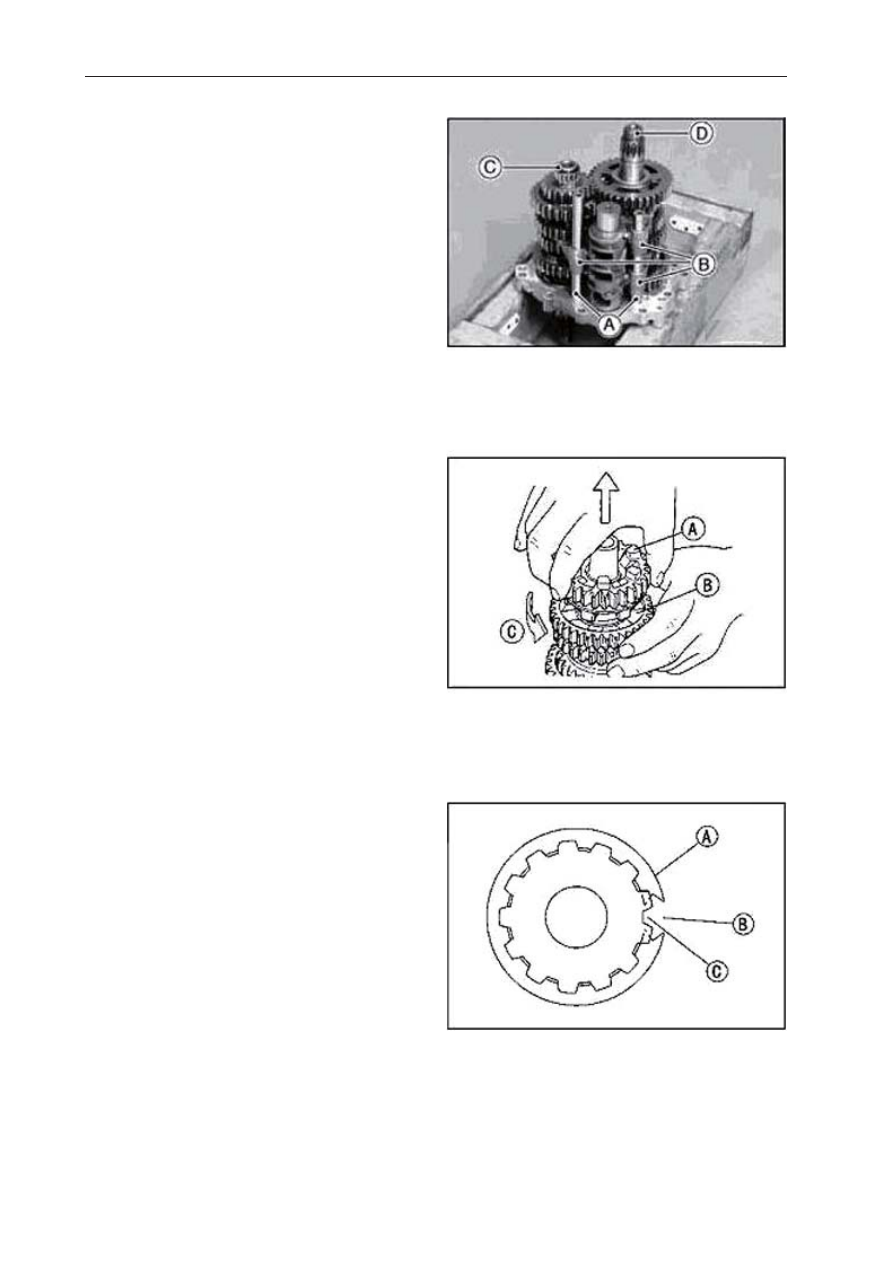

Remove:

Shift Rods [A]

Shift Forks [B]

Drive Shaft [C] and Output Shaft [D]

●

R e m o v e t h e c i r c l i p s , d i s a s s e m b l e t h e

transmission shafts.

●

Remove the

fi

fth 5th gear.

Transmission Shaft Assembly

●

Apply engine oil to the collar, needle bearing

and the shaft.

●

Install the collar to the shaft.

●

Replace all the removed circlips.

●

Install the circlips [A] so that the opening [B] is

aligned with a spline groove [C].