BMW Motorcycle (R1100RT, R1100RS, R850/1100GS, R850/1100R). Manual - part 31

31.8

[RS] Removing and installing fork

bridge

•

Separate connecting plug for ignition/steering

lock.

•

Unscrew handlebar mount on fork bridge.

•

Remove trim (1).

•

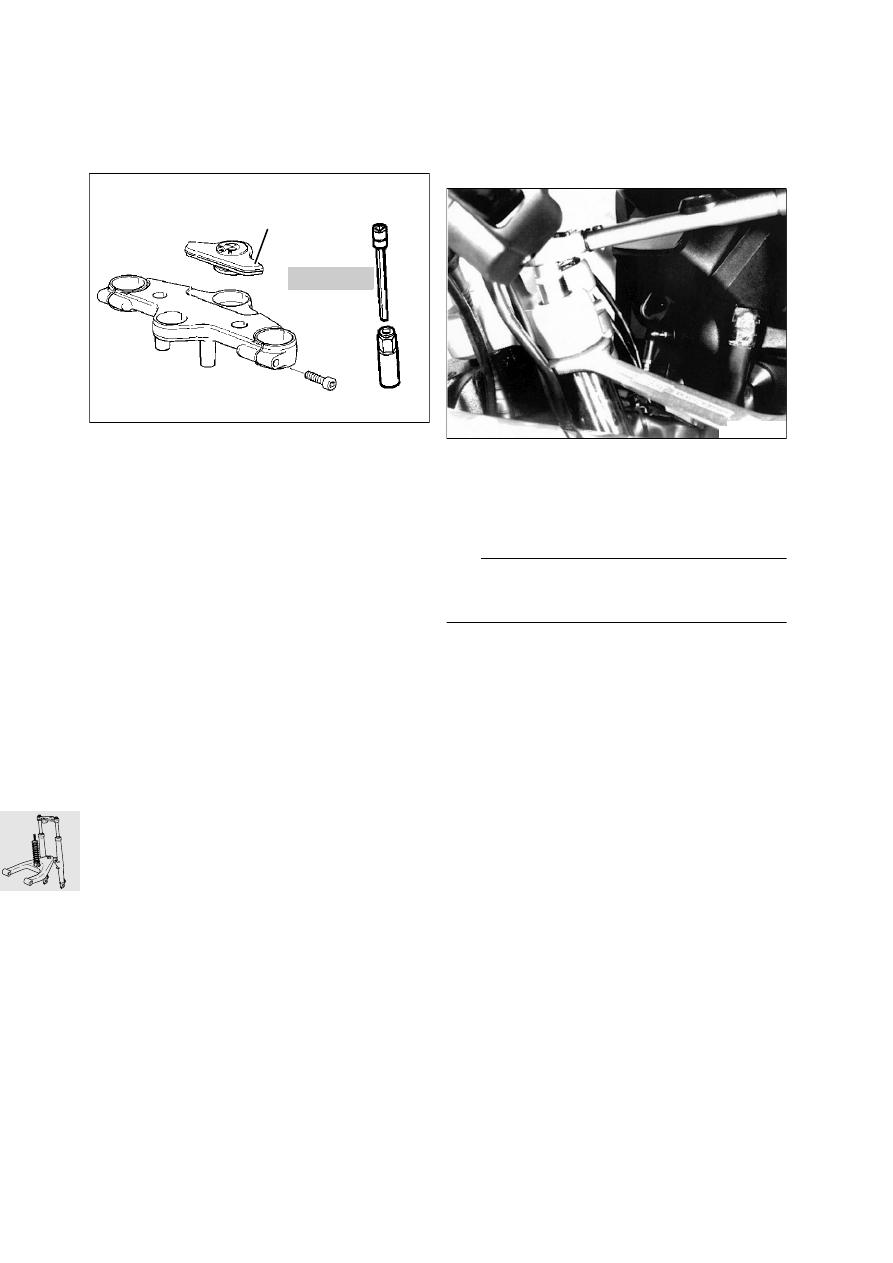

Heat ball joint mount on fork bridge to max.

120 °C and unscrew using Allen key socket

wrench insert, BMW No. 31 5 600.

•

Unscrew fixed tube clamp mount at top of fork

bridge.

•

Remove fork bridge.

•

Remove ignition/steering lock.

•

Install in the reverse order of work.

Projection of fixed tube beyond fork bridge:

................................ 5

± 0.5

mm (0.1969

± 0.01969

in)

X

Tightening torque:

Mount, fixed tube/fork bridge ....................... 22 Nm

Ball joint at fork bridge

(clean thread + Loctite 2701)...................... 130 Nm

[GS/R/RT] Removing and installing

fork bridge

•

Unscrew fuel tank and pull to the rear.

•

Separate connecting plug for ignition/steering

lock.

•

Detach handlebar from fork bridge.

•

Unfasten fixed tube screw connection at fork

bridge, preventing movement by holding hexa-

gon on fixed tube.

•

Unfasten screw connection between fork bridge

and frame.

L

Note:

Screw pin is a press fit in ball thrust bearing: remove

complete unit.

•

[R] Scheinwerferhalterung nach vorne ziehen.

•

Gabelbrücke abnehmen.

•

Zündlenkschloß ausbauen.

•

Einbau in umgekehrter Reihenfolge.

X

Tightening torque:

Screw connection between fork bridge and frame

(clean thread + Loctite 243)........................ 130 Nm

Threaded connection between fork bridge and fixed

tube (free from oil and grease)...................... 45 Nm

Handlebar to fork bridge .............................. 21 Nm

GS310030

31 5 600

1

j

120

w

GS000410