BMW Motorcycle (R1100RT, R1100RS, R850/1100GS, R850/1100R). Manual - part 5

00.30

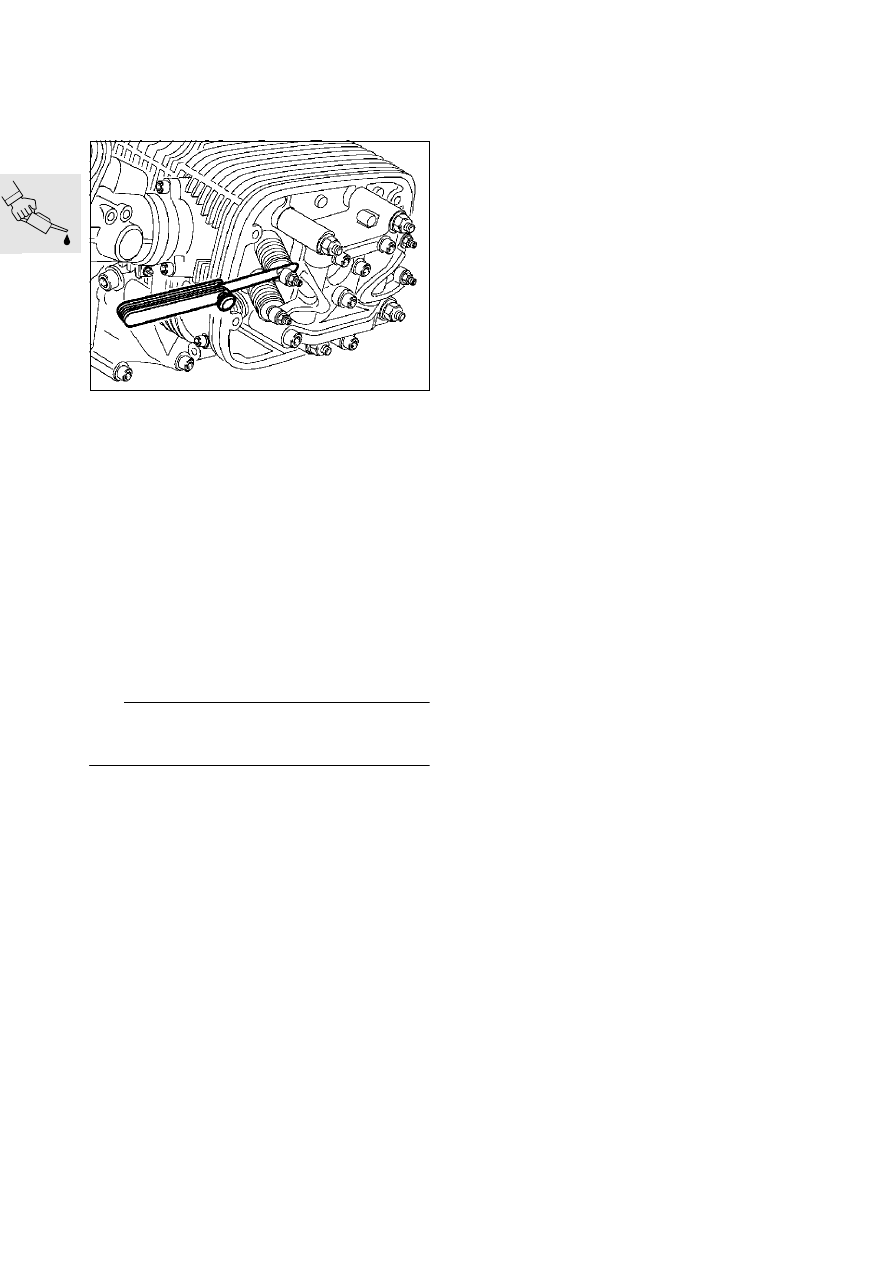

Checking/adjusting valve operating

clearances

(Inspection I, II, III)

•

Check valve clearance with feeler gauge and, if

necessary, correct with adjusting nut/lock.

Adjust valve clearances with the engine cold

(max. 35°C):

Inlet .......................................... 0.15 mm ( 0.006 in)

Exhaust .................................... 0.30 mm (0.012 in )

X

Tightening torque:

Locknut .......................................................... 8 Nm

•

Check valve clearance again; it must be possible

to insert the feeler gauge between valve stem

and rocker with only slight resistance to move-

ment.

•

Assemble in reverse order

e

Caution:

Make sure that gasket is correctly seated. Gaskets

and sealing faces must be free from oil or grease

X

Tightening torqu

Cover screw ................................................... 8 Nm

Spark plug (without lubricant) ....................... 20 Nm

RS110980