BMW AG Motorcycle (R 850 C, R 1200 C). Manual - part 19

31.6

•

Install by following the above work instructions in

the reverse order.

•

Using a socket wrench insert and internal hexa-

gon, BMW No. 31 5 600, tighten the ball joint at

the leading link.

e

Caution:

To prevent grease from escaping and the ingress of

dirt, ensure that sleeve is correctly located on ball

joint.

•

[ABS] Check sensor gap and adjust if necessary.

ABS –

Sensor gap:........ 0.50...0.55 mm (0.019...0.021 in)

X

Tightening torque:

Screw connection between fork bridge and frame

(clean thread + Loctite 243)........................ 130 Nm

Threaded connection between fork bridge and fixed

tube (free from oil and grease) ...................... 35 Nm

Handlebar at fork bridge

(install the lower clamping block facing forwards

(direction of arrow) and tighten the front clamp first)

.................................................................... 21 Nm

Instrument holder at fork bridge ..................... 9 Nm

Headlight holder at fork bridge ..................... 15 Nm

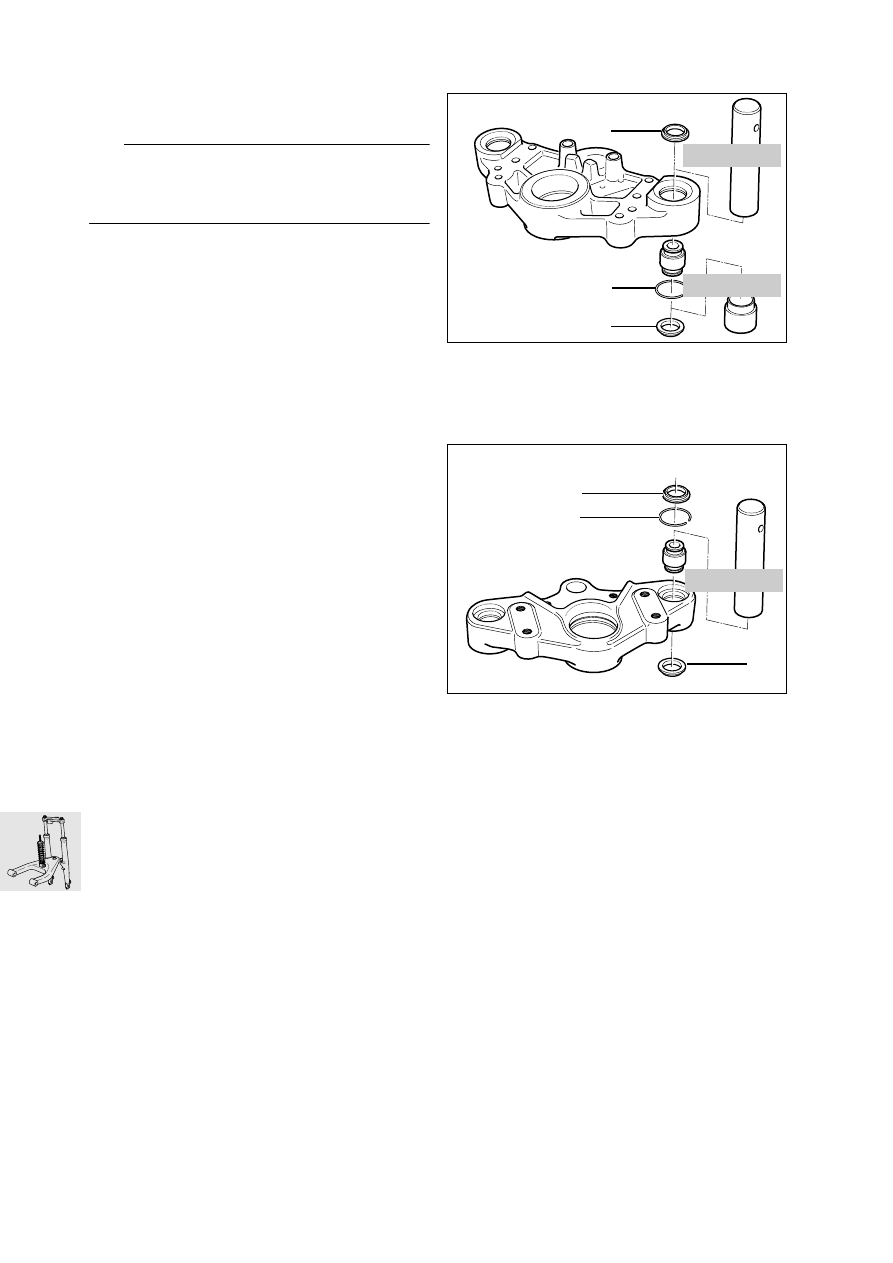

Removing and installing pot-type joints

•

Remove dust covers (1).

•

Remove snap ring (2).

•

Press out pot-type joint with pin,

BMW No. 31 5 661, and bushing,

BMW No. 31 5 662.

•

Press the pot-type joint in with pin,

BMW No. 31 5 661.

•

Install snap ring (2).

•

Install dust covers (1).

31 5 661

31 5 662

1

2

1

31 5 661

C310040

1

1

2