BMW AG Motorcycle (F 650 GS). Manual - part 27

32.12

32 72 305

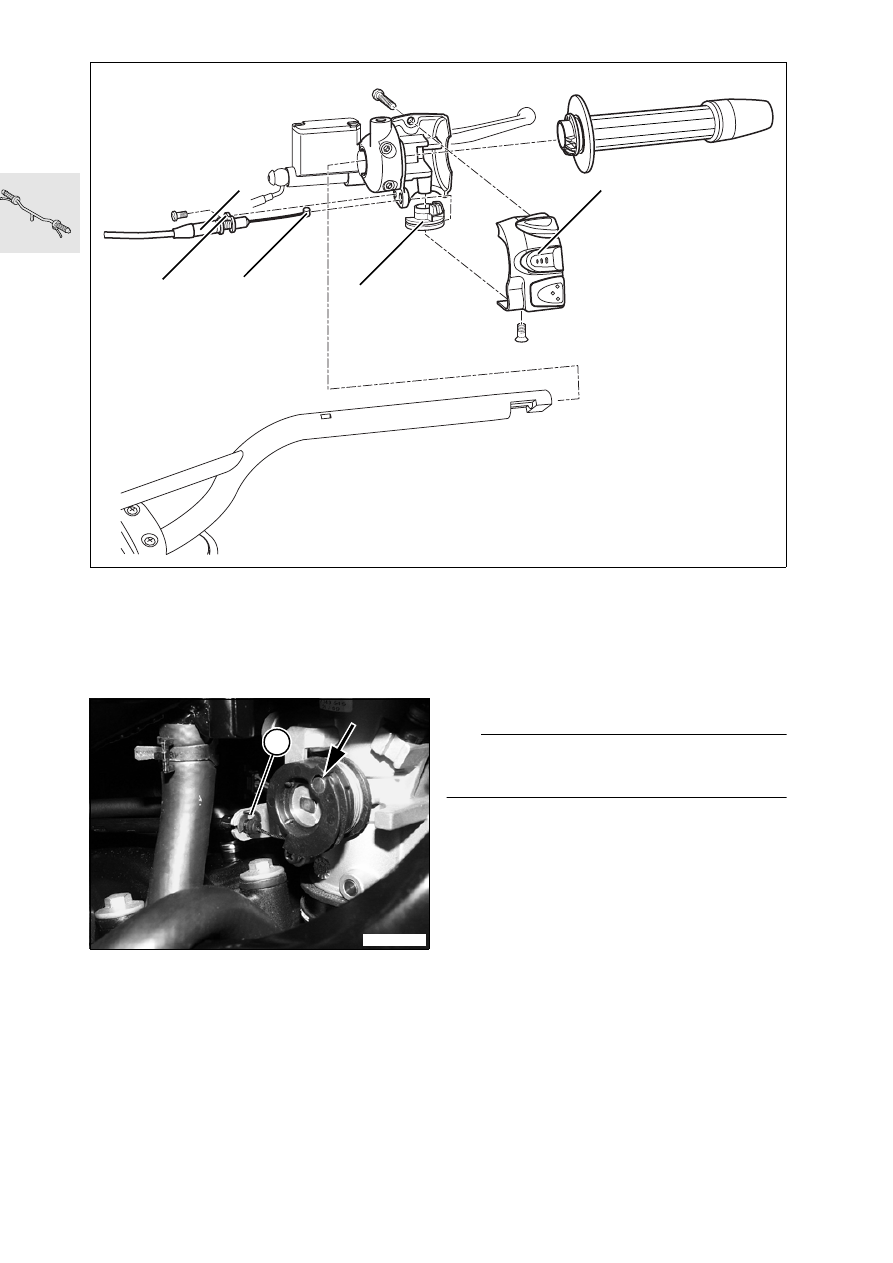

Removing and installing

throttle cable

–

Remove seat.

–

Remove left cover.

•

Disengage throttle cable from adapter (arrow).

•

Remove circlip (5) from throttle-cable holder and

disengage throttle cable.

•

Pull the cable out toward the handlebar.

•

Remove cover (4).

•

Remove fastener for throttle cable (1) from in-

strument cluster housing.

•

Disengage throttle-cable adapter (3) and disen-

gage nipple (4).

•

Remove the throttle cable.

•

Installation is the reverse of the removal proce-

dure: pay particular attention to the following.

L

Note:

Make sure that the cable is not kinked when in-

stalled.

•

Adjust throttle-cable play with adjusting

screw (5).

Throttle cable play................approx. 1 mm (0.04 in)

X

Tightening torques:

Cover of multi-function switch ........................ 1 Nm

E320170

1

4

3

2

5

E320180

5