Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 883

4.5.2

Wheels and Tires, Radial and Lateral

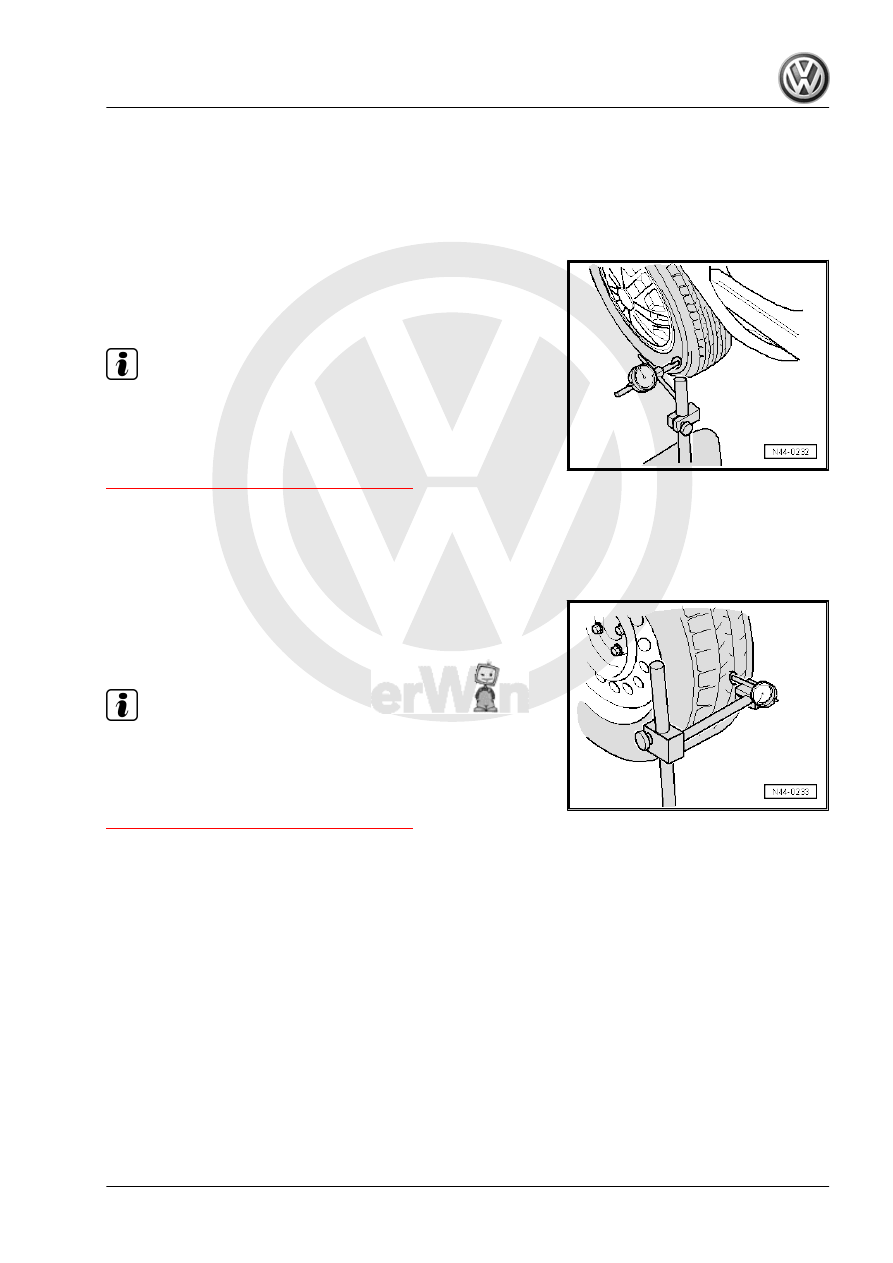

Run Out, Checking with Tire Dial Gauge

Checking Lateral Run-Out

– Preload the Tire Dial Gauge approximately 2 mm.

– Position the Tire Dial Gauge on the side wall of the tire.

– Rotate the wheel slowly.

– Note the smallest and the largest dial readings.

Note

If the difference is greater than 1.3 mm, the lateral run-out is too

great.

In this case, lateral run-out can be reduced by matched mounting

of the tire. Refer to

⇒ “4.7 Wheels and Tires, Matching”, page 318

Peak values on the Tire Dial Gauge due to small irregularities in

the rubber may be disregarded.

Checking Radial Run-Out

– Preload the Tire Dial Gauge approximately 2 mm.

– Position the Tire Dial Gauge on the tread of the tire.

– Rotate the wheel slowly.

– Note the smallest and the largest dial readings.

Note

If the difference is greater than 1 mm, the radial run-out is too

great.

In this case, radial run-out can be reduced by matched mounting

of the tire. Refer to

⇒ “4.7 Wheels and Tires, Matching”, page 318

4.6

Rim Radial and Lateral Run-Out,

Checking

– Mount the rim on the Balancing Machine .

– Use the Wheel Centering System Adapter - VAS5271- .

– Preload the Tire Dial Gauge approximately 2 mm.

– Turn the rim slowly.