Toyota FJ Cruiser (GSJ 10, 15 series). Instruction - part 102

1GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES–363

ES

•

Read freeze frame data using an intelligent tester. Freeze frame data record the engine condition when

malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle

was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and

other data, from the time the malfunction occurred.

(a) Turn the ignition switch OFF and wait for 10 seconds.

(b) Turn the ignition switch ON.

(c) Turn the ignition switch OFF and wait for 10 seconds.

(d) Connect an intelligent tester to the DLC3.

(e) Turn the ignition switch ON and turn the tester ON.

(f)

Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(g) Confirm DTCs and freeze frame data.

If any EVAP system DTCs are set, the malfunctioning

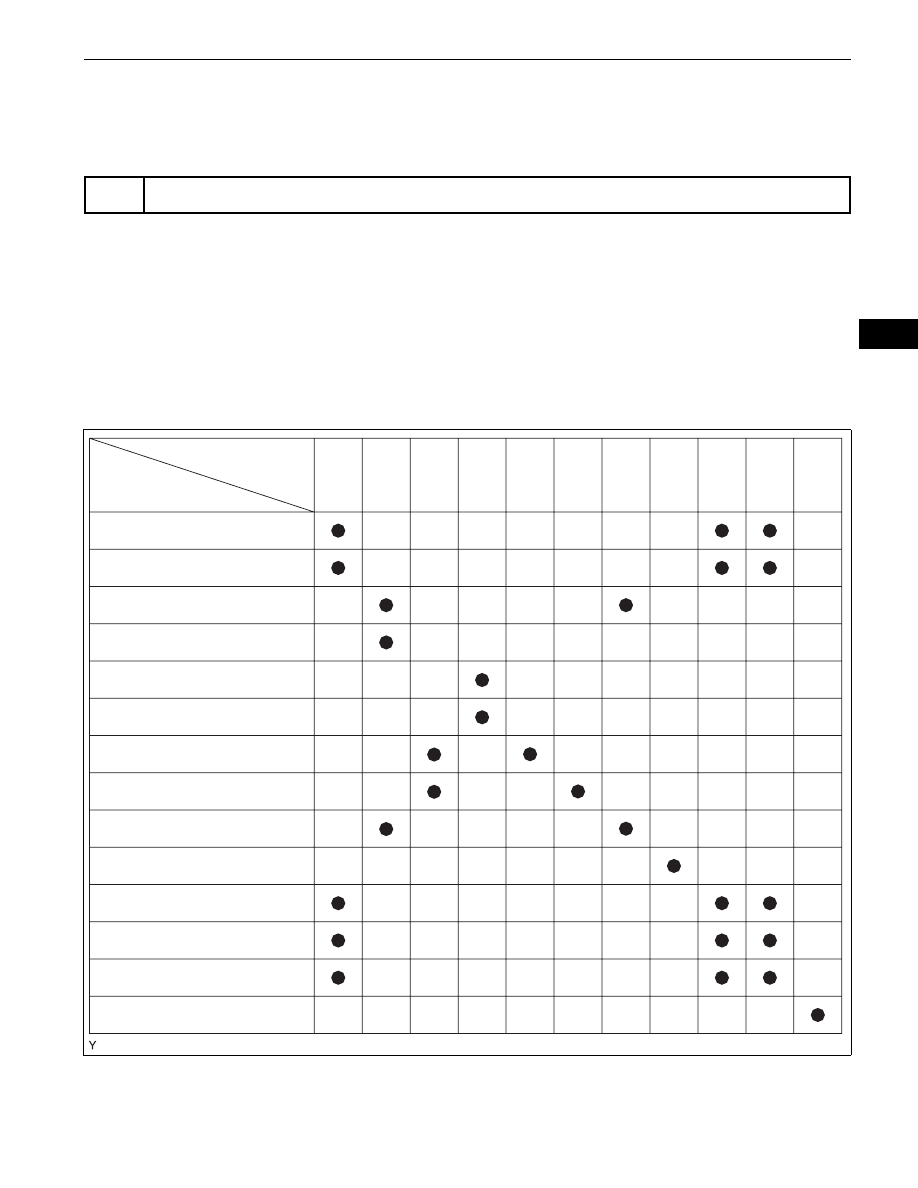

area can be determined using the table below.

1

CONFIRM DTC

Malfunctioning Areas

Reference orifice clogged

Reference orifice high-flow

Purge VSV stuck open

Purge VSV stuck closed

Canister pressure sensor fixed

output

Canister pressure sensor noise

Canister pressure sensor high

output

Canister pressure sensor low

output

Gross leak

Small leak

Leak detection pump stuck OFF

Leak detection pump stuck ON

Vent valve stuck closed

Vent valve stuck open (vent)

DTCs

P043E

P043F

P0441

P0451 P0452 P0453 P0455 P0456

P2401

P2402

P2419 P2420

P0450

A106731E11