Suzuki Grand Vitara JB416 / JB420 / JB419. Manual - part 235

3B-11 Differential: Front

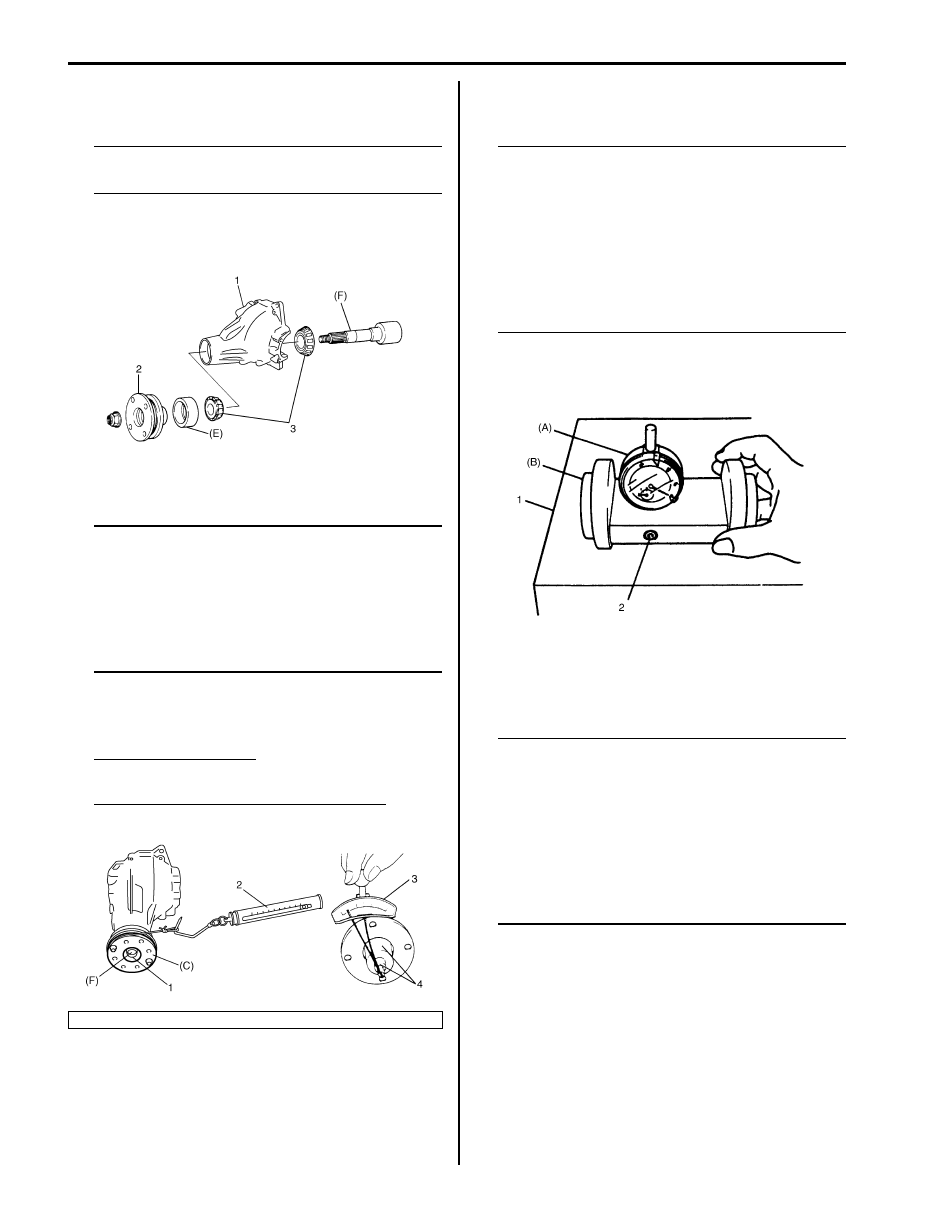

9) Install special tools with bearings (3) and flange (2)

to differential carrier (1).

NOTE

This installation requires no spacer or oil

seal.

Special tool

(E): 09951–46010

(F): 09926–78311–002

10) Tighten flange nut (1) so that specified bearing

preload is obtained.

NOTE

• Before taking measurement with spring

balance (2) or torque wrench (3), check for

rotation by hand and apply small amount

of differential oil to bearings.

• On measuring preload, rotate the drive

bevel pinion about 1 rotation per 2

seconds.

Special tool

(C): 09922–75222

(F): 09926–78311–002

Pinion bearing preload

0.9 – 1.7 N

⋅m (9.0 – 17.0 kg-cm, 7.8 – 14.7 lb-in.)

Spring measure reading with special tool

20 – 40 N (2.0 – 4.0 kg, 4.4 – 8.8 lb)

11) Set dial gauge to mounting dummy and make 0

(zero) adjustment on surface plate (1).

NOTE

• When setting dial gauge to mounting

dummy, tighten screw (2) lightly. Be careful

not to overtighten it, which will cause

damage to dial gauge.

• With dial gauge set, turn dummy back and

force by hand a couple of times and attain

accurate 0 (zero) adjustment.

• It is desirable that short pointer indicates

beyond 2 mm when long one is at 0 (zero).

Special tool

(A): 09900–20607

(B): 09926–78320

12) Place zero-adjusted mounting dummy and dial

gauge set on pinion mounting dummy and take

measurement between zero position and extended

dial gauge measuring tip.

NOTE

• Repeat turning back and force of dummy

and measure distance as far as top surface

of pinion dummy accurately.

• When dial gauge measuring tip extends

from 0 (zero) position, pointer turns

counterclockwise.

• Measured value may exceed 1 mm.

Therefore, it is also necessary to know

reading of short pointer.

4. Socket with adapter

I5JB0A321030-01

I5JB0A321031-01

IYSQ01322033-01