Suzuki Grand Vitara JB416 / JB420 / JB419. Manual - part 222

2C-11 Rear Suspension:

2) Tighten parking cable hanger bolt (1) to specified

torque.

Tightening torque

Parking cable hanger bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

3) Lower jack and remove floor jack from lower arm.

4) Install rear wheels and lower hoist.

5) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 100 N·m (10.0 kgf-m, 72.5 lb-ft)

6) Tighten control rod mount nut and control rod outer

bolt to specified torque with vehicle weight on

suspension.

CAUTION

!

• It is the most desirable to have vehicle off

hoist and in non-loaded condition when

tightening them.

• Tighten control rod washer with match

marks aligned.

Tightening torque

Control rod mount nut: 135 N·m (13.5 kgf-m,

98.0 lb-ft)

Control rod outer bolt: 135 N·m (13.5 kgf-m, 98.0

lb-ft)

7) Check rear toe and camber adjust it as necessary.

For check and adjustment procedures, refer to “Rear

Wheel Alignment Inspection and Adjustment”.

Control Rod / Bushing Disassembly and

Assembly

S6JB0A2306009

Disassembly

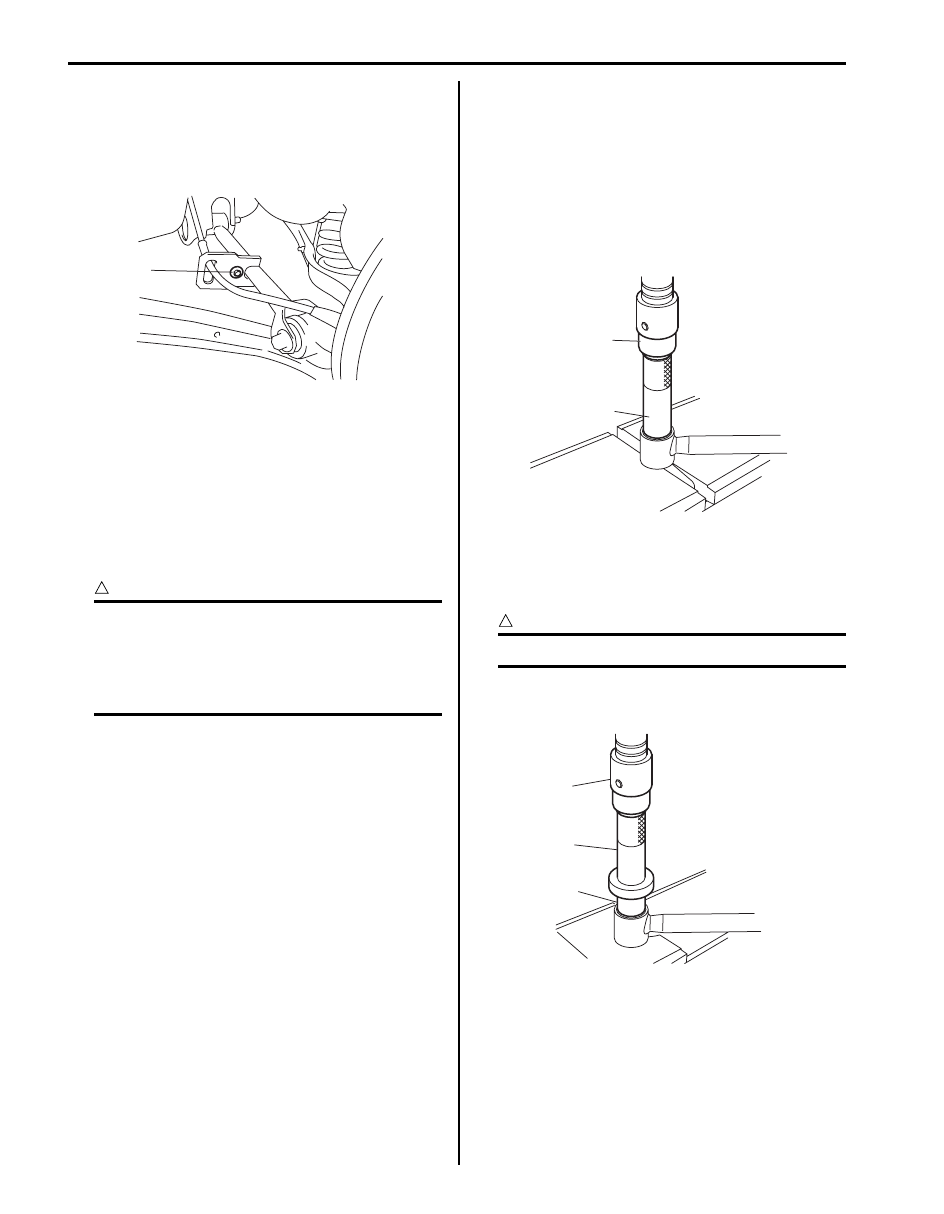

1) Push out control rod bushing by using hydraulic

press (1) and special tool.

Special tool

(A): 09913–84510

Assembly

1) Press-fit control rod bushing (1) by using press (2)

and special tool.

CAUTION

!

Be sure to use new bushing.

Special tool

(A): 09913–85210

1,(a)

I5JB0A230022-01

(A)

1

I5JB0A230023-02

1

2

(A)

I5JB0A230082-01