Suzuki Grand Vitara JB416 / JB420 / JB419. Manual - part 133

1D-58 Engine Mechanical: For M16A Engine with VVT

2) Next, check bearing cap bore diameter without

bearing. On mating surface of cylinder block, five

alphabets are stamped as shown in the figure.

Three kinds of alphabets (“A”, “B” and “C”) or

numbers (“1”, “2” and “3”) represent the following

cap bore diameters.

Stamped alphabets or numbers on cylinder block

represent bearing cap bore diameter marked with an

arrow in the figure respectively.

For example, stamped “A” or “1” indicates that

corresponding bearing cap bore diameter is 56.0000

– 56.0060 mm (2.2048 – 2.2049 in.).

Crankshaft bearing cap bore

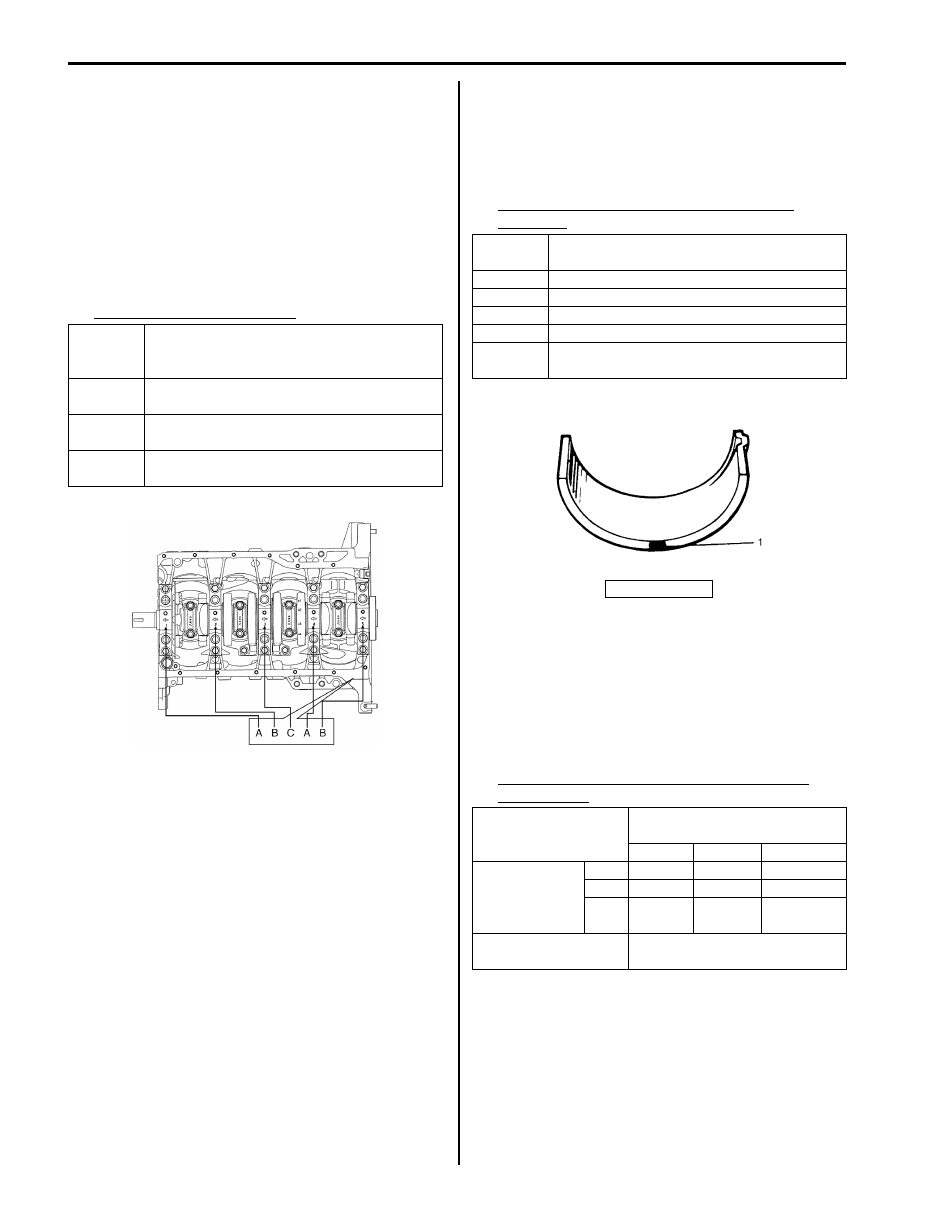

3) There are 5 kinds of standard bearings differing in

thickness. To distinguish them, they are painted in

the following colors at the position as indicated in the

figure.

Each color indicated the following thickness at the

center of bearing.

Standard size of crankshaft main bearing

thickness

4) From number stamped on crank web No.2 and

alphabets stamped on cylinder block, determine new

standard bearing to be installed to journal, by

referring to the table shown.

For example, if number stamped on crank web No.2

is “1” and alphabet stamped on cylinder block is “B”,

install a new standard bearing painted in “Brown” to

its journal.

New standard size crankshaft main bearing

specification

Stamped

alphabet

(number)

Bearing cap bore diameter (without

bearing)

A (1)

56.0000 – 56.0060 mm

(2.2048 – 2.2049 in.)

B (2)

56.0061 – 56.0120 mm

(2.2050 – 2.2051 in.)

C (3)

56.0121 – 56.0180 mm

(2.2052 – 2.2054 in.)

I2RH0B140143-02

Color

painted

Bearing thickness

Purple

1.992 – 1.996 mm (0.07843 – 0.07858 in.)

Brown

1.995 – 1.999 mm (0.07855 – 0.07870 in.)

Green

1.998 – 2.002 mm (0.07867 – 0.07882 in.)

Black

2.001 – 2.005 mm (0.07878 – 0.07893 in.)

Colorless

(no paint)

2.004 – 2.008 mm (0.07890 – 0.07906 in.)

1. Paint

Number stamped on crank

web No.2 (Journal diameter)

1

2

3

Alphabet

stamped on

cylinder block

(Cap bore dia.)

A (1) Purple

Brown

Green

B (2) Brown

Green

Black

C (3) Green

Black

Colorless

New standard bearing to be

installed

I2RH01140191-01