Suzuki Grand Vitara JB416 / JB420 / JB419. Manual - part 130

1D-46 Engine Mechanical: For M16A Engine with VVT

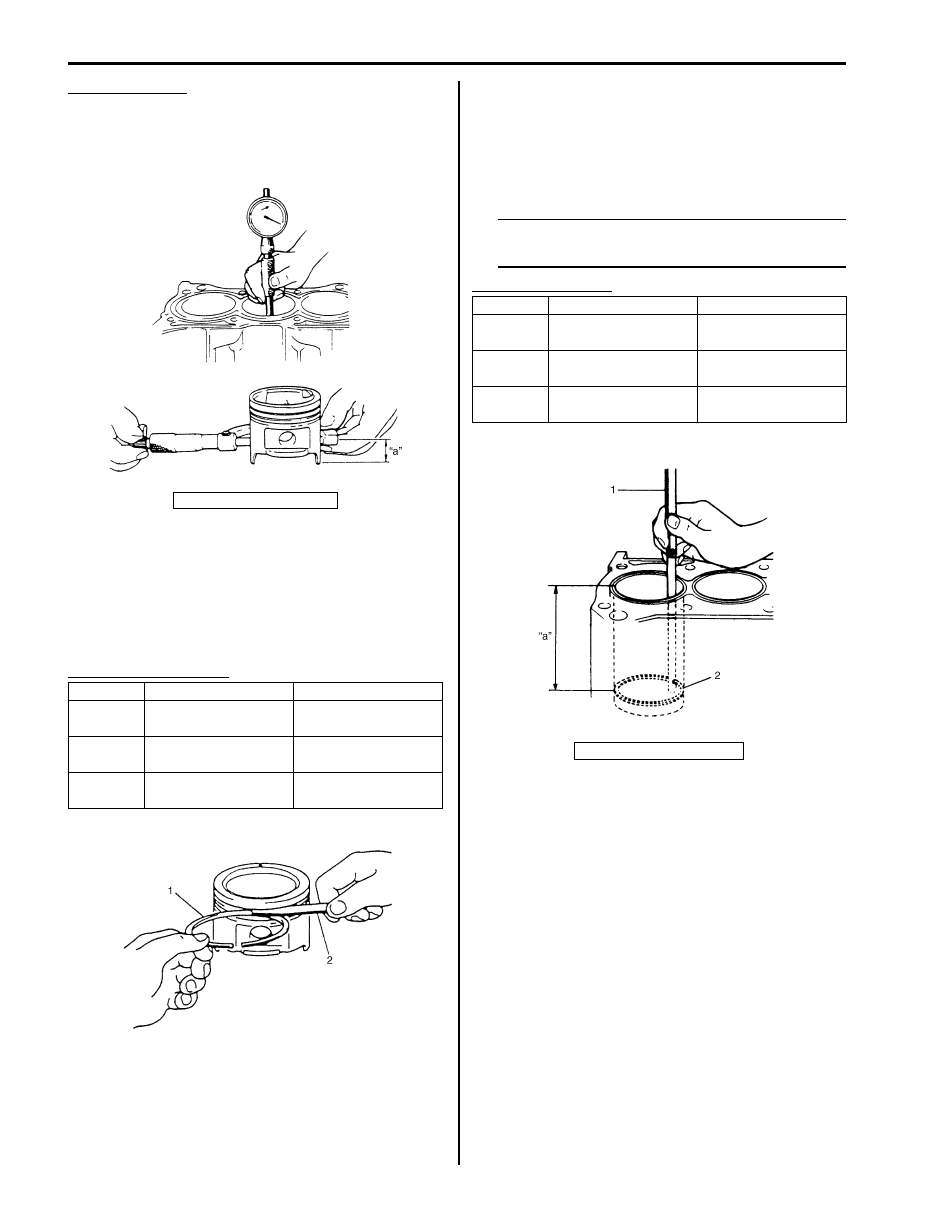

Piston clearance

Standard: 0.032 – 0.061 mm (0.0013 – 0.0024 in.)

Standard (piston with coating (new one)): 0.016 –

0.045 mm (0.0006 – 0.0018 in.)

Limit: 0.161 mm (0.0065 in.)

Ring groove clearance

Before checking, piston grooves must be clean, dry and

free of carbon deposits.

Fit new piston ring (1) into piston groove, and measure

clearance between ring and ring land by using thickness

gauge (2). If clearance is out of specification, replace

piston.

Ring groove clearance

Piston Ring

Piston ring end gap

To measure end gap, insert piston ring (2) into cylinder

bore and then measure the gap by using thickness

gauge (1).

If measured gap exceeds limit, replace ring.

NOTE

Decarbonize and clean top of cylinder bore

before inserting piston ring.

Piston ring end gap

“a”: 19.5 mm (0.77 in.)

Standard

Limit

Top ring

0.03 – 0.07 mm

(0.0012 – 0.0028 in.)

0.12 mm (0.0047 in.)

2nd ring

0.02 – 0.06 mm

(0.0008 – 0.0024 in.)

0.10 mm (0.0039 in.)

Oil ring

0.03 – 0.17 mm

(0.0012 – 0.0067 in.)

—

I4RS0A140022-01

I2RH01140159-01

Item

Standard

Limit

Top ring

0.20 – 0.35 mm

(0.0079 – 0.0138 in.)

0.7 mm (0.0276 in.)

2nd ring

0.35 – 0.50 mm

(0.0138 – 0.0197 in.)

1.0 mm (0.0394 in.)

Oil ring

0.20 – 0.70 mm

(0.0079 – 0.0276 in.)

1.2 mm (0.0472 in.)

“a”: 120 mm (4.72 in.)

I2RH01140161-01