Suzuki Grand Vitara JB416 / JB420 / JB419. Manual - part 21

1A-31 Engine General Information and Diagnosis: For Petrol Engine Model

DTC Check

S6JB0A1114003

NOTE

The MIL is turned on when the ECM and/or

TCM detect malfunction(s). Each ECM and

TCM stores diagnostic information as the

diagnostic trouble code (DTC) in its memory

and outputs the DTC to the scan tool.

Therefore, check both of the ECM and TCM

for any DTC with the scan tool because the

DTC stored in ECM and TCM is not read and

displayed at a time. However, each of the

ECM and TCM needs not to be checked with

the generic scan tool because the DTC stored

in ECM and TCM is read and displayed at a

time.

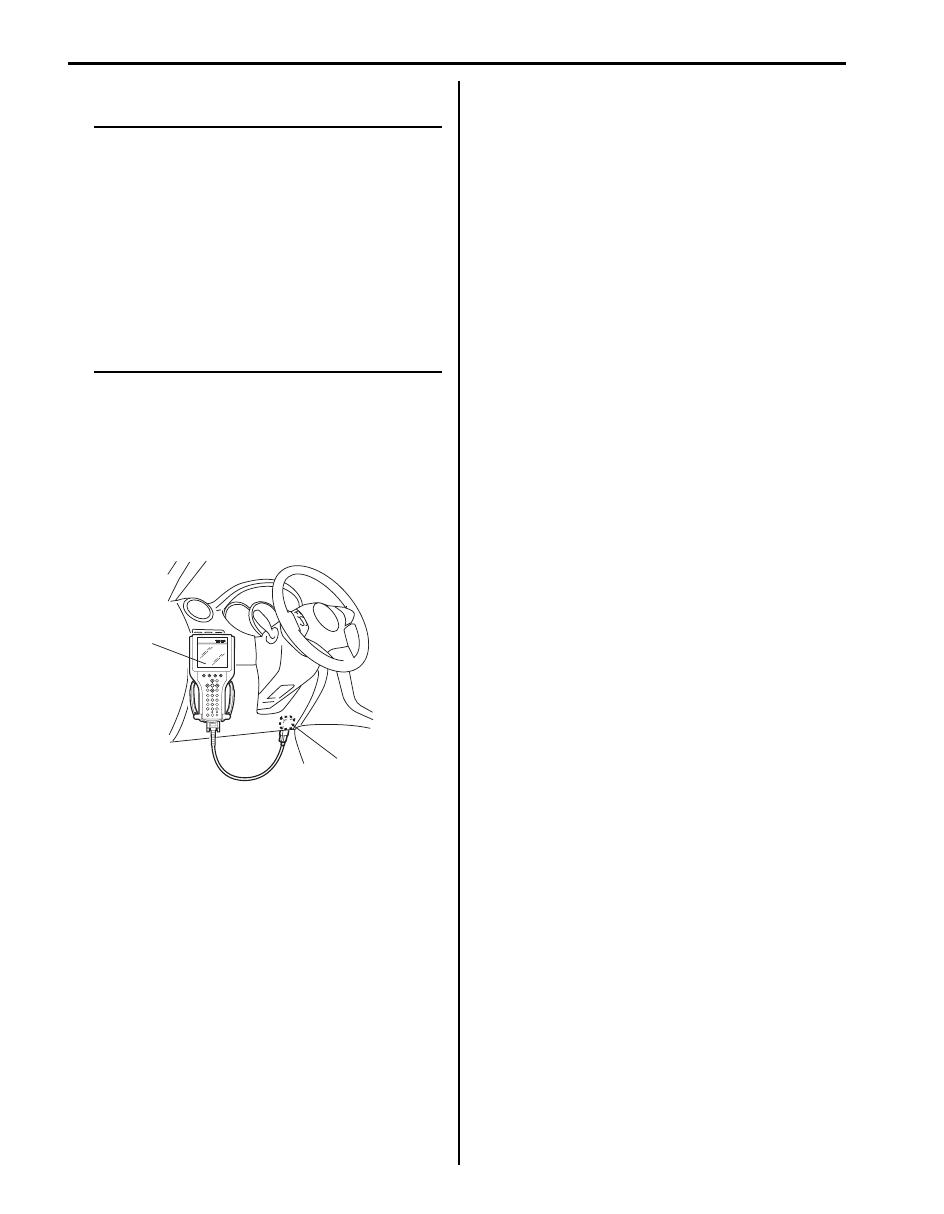

Using Scan Tool

1) Prepare SUZUKI scan tool or OBD generic scan tool

(Euro OBD model).

2) With ignition switch turned OFF, connect it to data

link connector (DLC) (1) located on underside of

instrument panel at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC, pending DTC and freeze frame data

according to instructions displayed on scan tool and

print them or write them down. Refer to scan tool

operator’s manual for further details.

If communication between scan tool and ECM is not

possible, check if scan tool is communicable by

connecting it to ECM in another vehicle. If

communication is possible in this case, scan tool is

in good condition. Then check data link connector

and serial data line (circuit) in the vehicle with which

communication was not possible. If connector and

circuit are OK, check that power supply and ground

circuits of ECM and DLC are in good condition

referring to “ECM Power and Ground Circuit Check:

For Petrol Engine Model”.

5) After completing the check, turn ignition switch OFF

and disconnect scan tool from data link connector.

(A)

1

I5JB0A110019-01