Suzuki Grand Vitara JB416 / JB420 / JB419. Manual - part 9

Maintenance and Lubrication: 0B-6

Repair Instructions

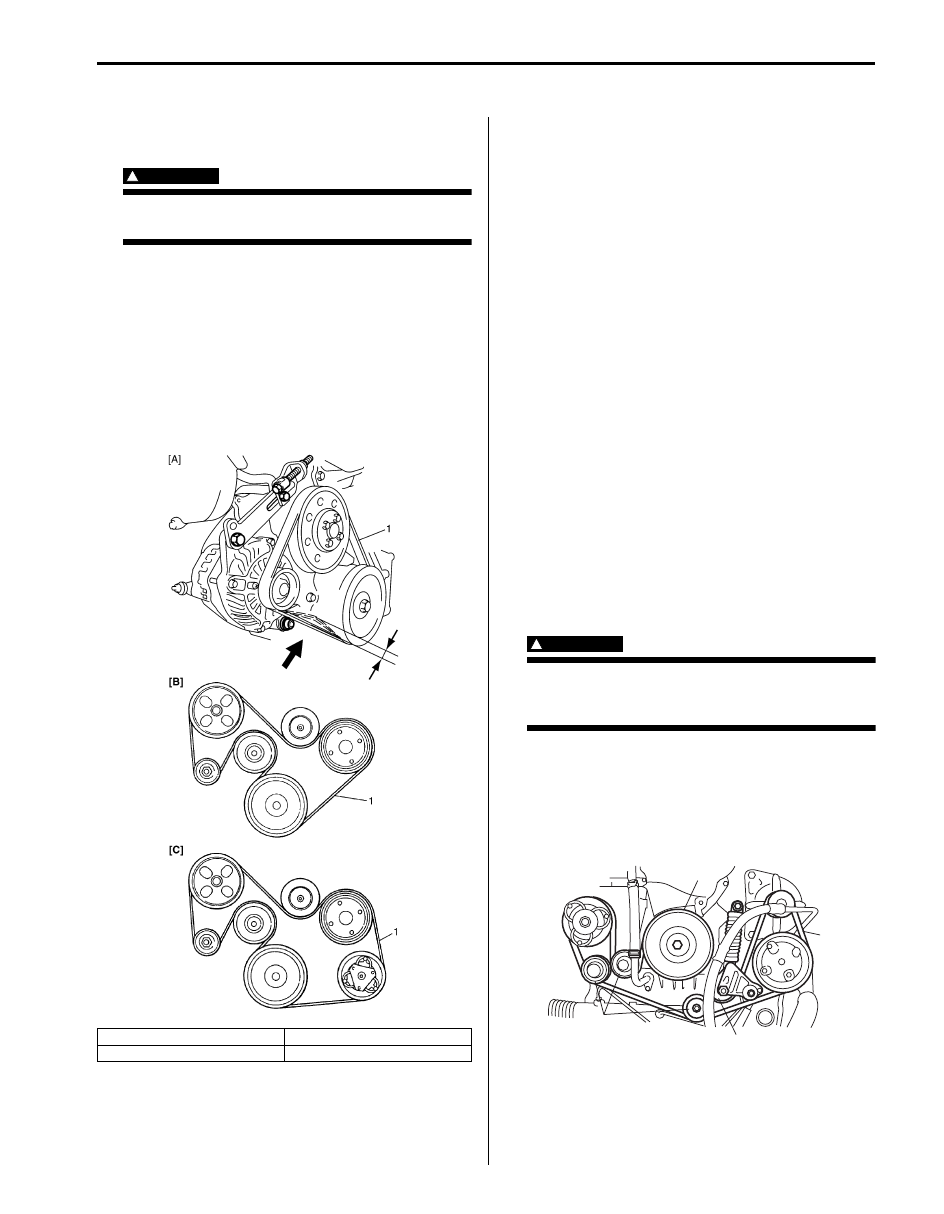

Engine Accessory Drive Belt Inspection (Petrol

Engine Model)

S6JB0A0206001

WARNING

!

All inspection and replacement are to be

performed with ENGINE NOT RUNNING.

Water Pump and Generator Drive Belt

Inspect belt for cracks, cuts, deformation, wear

cleanliness and tension. If any defect exists, adjust or

replace.

For belt inspection, refer to “Water Pump and Generator

Drive Belt Tension Inspection and Adjustment (For M16

Engine): For Petrol Engine Model in Section 1J” or

“Water Pump and Generator Drive Belt On-Vehicle

Inspection (For J20 Engine): For Petrol Engine Model in

Section 1J”.

Power Steering Pump and A/C Compressor (If

Equipped) Drive Belt (M16 Engine)

Inspect belt for cracks, cuts, deformation, wear

cleanliness and tension. If any defect exists, adjust or

replace.

For inspection, refer to “P/S Pump and A/C Compressor

(If Equipped) Drive Belt Inspection and Adjustment

(M16A Engine Model) in Section 6C”.

Engine Accessory Drive Belt Replacement

(Petrol Engine Model)

S6JB0A0206002

Water Pump and Generator Drive Belt

Replace belt referring to “Water Pump and Generator

Drive Belt Removal and Installation (For M16 Engine):

For Petrol Engine Model in Section 1J” or “Water Pump

and Generator Drive Belt Removal and Installation (For

J20 Engine): For Petrol Engine Model in Section 1J”.

Power Steering Pump and A/C Compressor (If

Equipped) Drive Belt (M16 Engine)

Replace belt and then adjust belt tension referring to “P/

S Pump and A/C Compressor (If Equipped) Drive Belt

Removal and Installation (M16A Engine Model) in

Section 6C”.

Engine Accessory Drive Belt, Tensioner and

Idler Replacement (Diesel Engine Model)

S6JB0A0206041

WARNING

!

Replacement must be performed with battery

negative cable disconnected to avoid a

personal injury.

Replace belt (1), tensioner (2) and idlers (3) with new

ones referring to “Accessory Drive Belt and Idler Pulley

Removal and Installation: For Diesel Engine Model in

Section 1J”.

Check crankshaft pulley (4) for wear and damage, and

replace it as necessary.

[A]: M16 engine

[C]: J20 engine with A/C

[B]: J20 engine without A/C

I5JB0A020018-01

1

2

3

4

I5JB0B020001-02