Suzuki Grand Vitara JB419. Manual - part 109

Manual Transmission/Transaxle: 5B-12

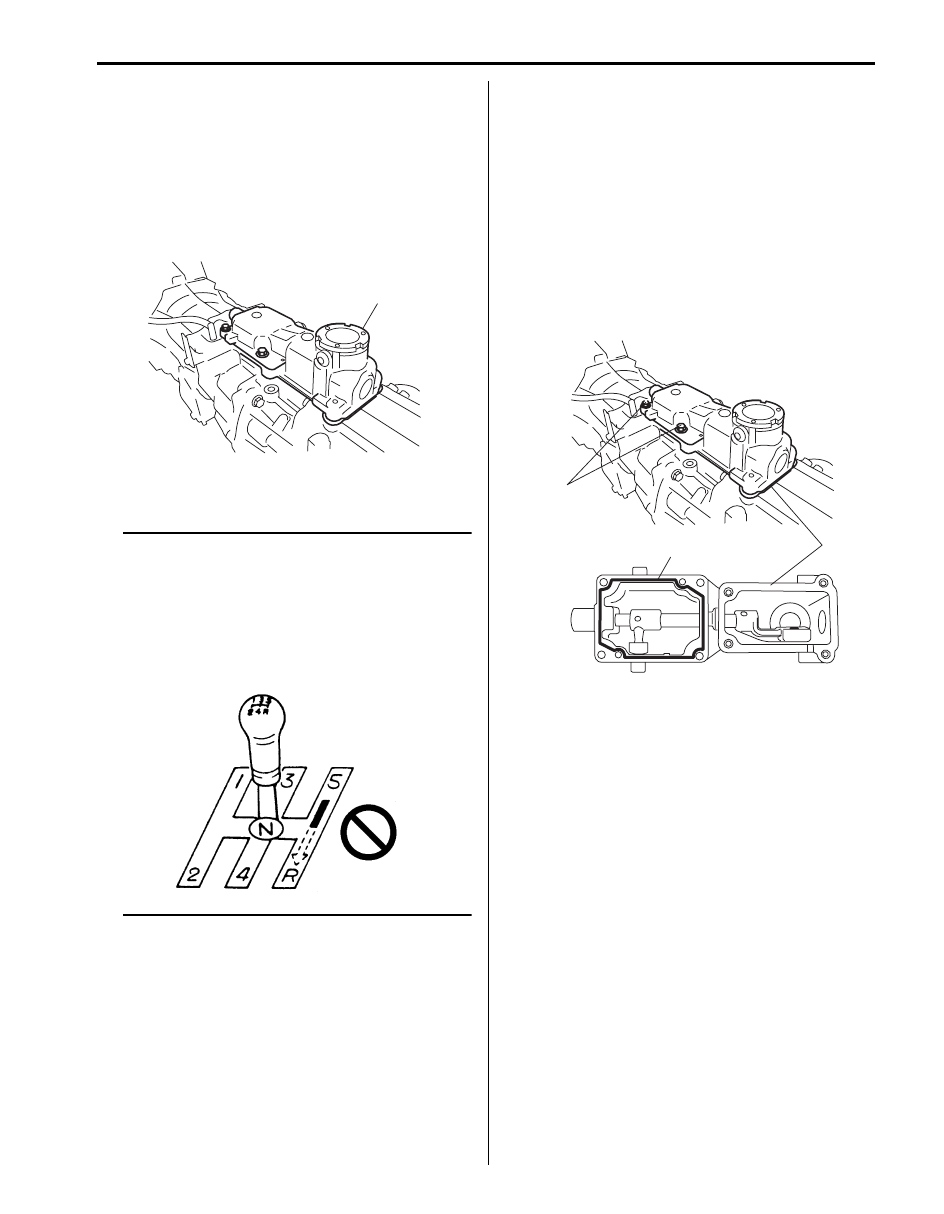

Gear Shift Lever Case Assembly Removal and

Installation

S5JB0B5206014

Removal

1) Dismount transmission assembly referring to

“Manual Transmission Assembly Dismounting and

Remounting”

2) Remove gear shift lever case assembly (1) from

transmission adapter case.

Installation

NOTE

• Install gear shift lever case to transmission

adapter case without using sealant for

functional check.

• Install shift control lever and check to

make sure that it shifts smoothly

according to shift pattern as shown in the

figure.

1) Clean mating surface of both adapter case and gear

shift lever case (2), and uniformly apply sealant to

lever case as shown in figure by such amount that its

section is 1.5 mm (0.059 in.) in diameter, and then

mate it with gear shift lever case.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

2) Install lever case to adapter case, and then tighten

new lever case bolts (1) to specified torque.

Tightening torque

Gear shift lever front case bolt (a): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

3) Remount transmission assembly referring to

“Manual Transmission Assembly Dismounting and

Remounting”

1

I5JB0B520013-01

I5JB0A520010-01

1, (a)

2

“A”

I5JB0B520014-02