Suzuki Grand Vitara JB627. Manual - part 229

5A-100 Automatic Transmission/Transaxle:

Transmission Fluid Temperature Sensor

Removal and Installation

S6JB0B5106023

Removal

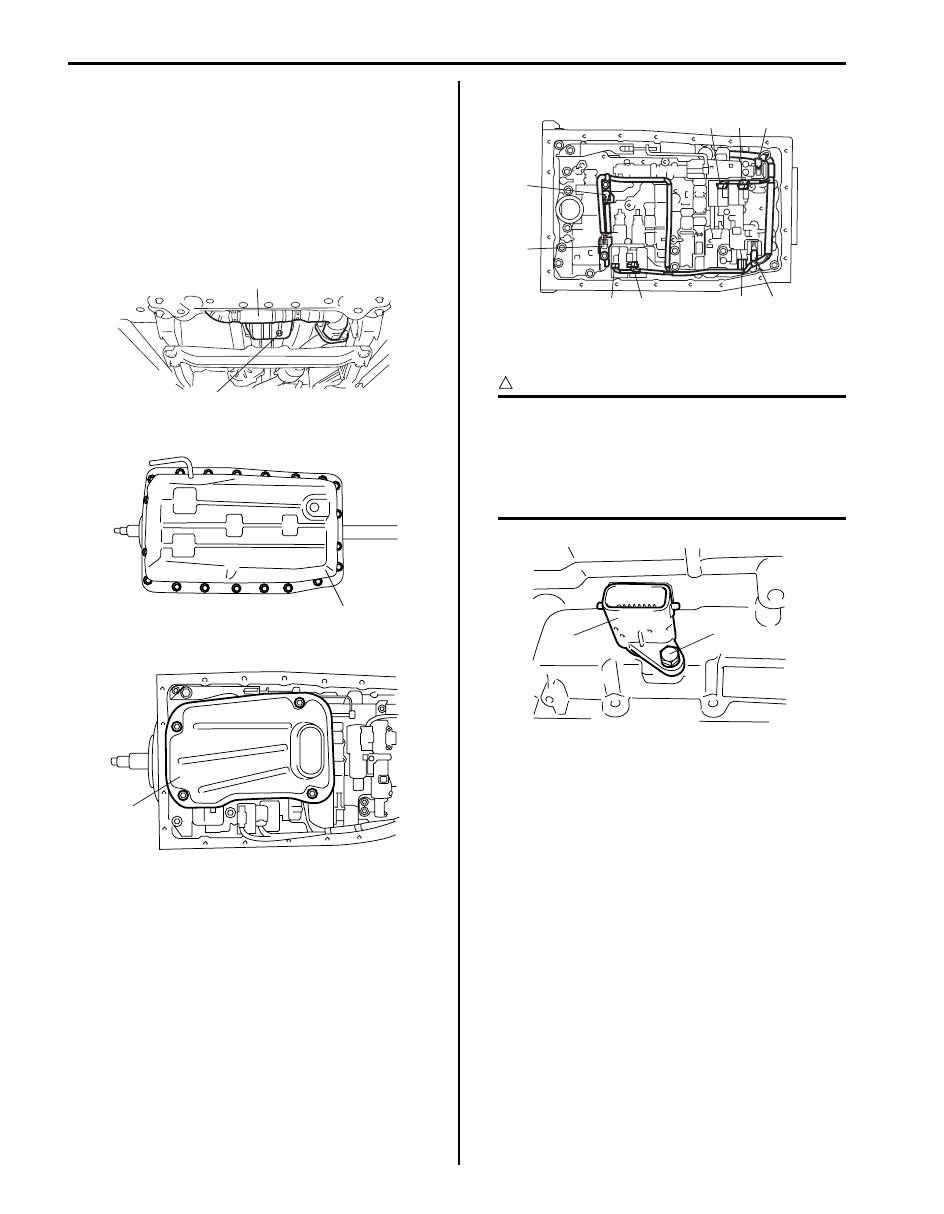

1) Disconnect negative cable at battery.

2) Pull out fluid level gauge and lift up vehicle.

3) Remove exhaust No.1 pipe (1).

4) Remove drain plug (2) and drain A/T fluid.

5) Install drain plug (2).

6) Remove A/T oil pan (1).

7) Remove A/T oil strainer (1).

8) Remove transmission fluid temperature sensor A (8)

and B (9) (if equipped).

9) Disconnect shift solenoid-A connector (1), shift

solenoid-B connector (2), shift solenoid-E connector

(3), TCC solenoid connector (4), Pressure control

solenoid-A connector (5), Pressure control solenoid-

B connector (6) and Pressure control solenoid-C

connector (7).

10) Remove solenoid valves.

11) After removing bolt (1) pull out transmission wire

connector (2) from transmission case.

CAUTION

!

When pulling transmission wire harness out

of transmission case, take care not to

damage connectors and transmission fluid

temperature sensors at narrow exist of case.

Careless sensor treatment might cause

sensor malfunction.

Installation

Remove removal procedure to install transmission fluid

temperature sensor, noting the following points.

• For details of solenoid valves and their connectors

installation, refer to “Automatic Transmission Unit

Assembly”. Use new O-ring.

• For details of A/T oil pan installation, refer to

“Automatic Transmission Unit Assembly”.

• Tighten exhaust No.1 pipe bolts & nuts.

• Fill A/T fluid and check fluid level according to

procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

2

1

I6JB01510026-01

1

I4JA01512025-01

1

I4JA01512026-01

7

8

9

5

3

1

2

4

6

I6JB0B510008-01

2

1

I4JA01512070-01