Suzuki Grand Vitara JB627. Manual - part 211

5A-28 Automatic Transmission/Transaxle:

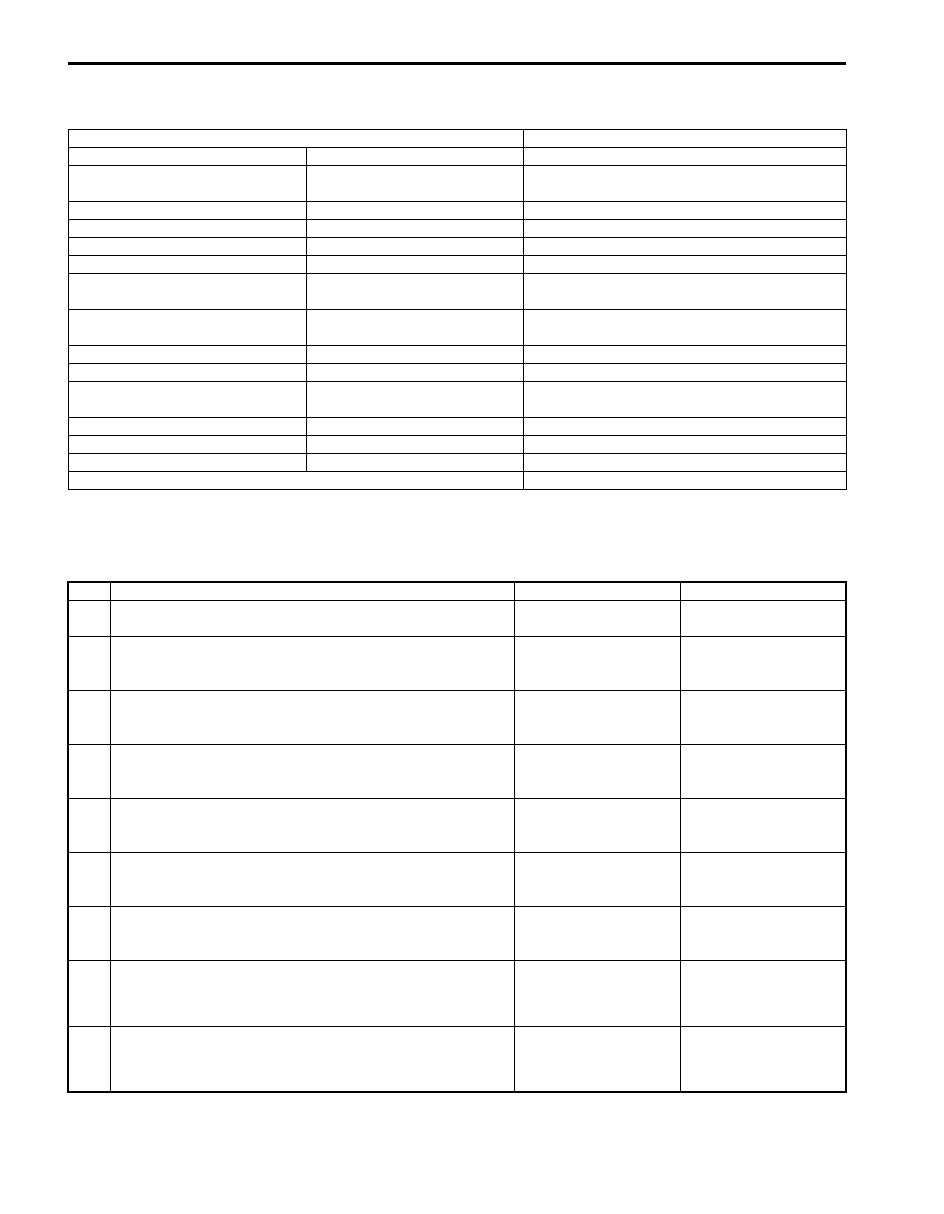

Visual Inspection

S6JB0B5104008

Visually check the following parts and systems.

A/T Basic Check

S6JB0B5104009

This check is important for troubleshooting when TCM has detected no DTC and no abnormality has been noted in

visual inspection. Follow the flow table carefully.

Inspection Item

Referring

A/T fluid

Level, leakage, color

A/T fluid hoses

Disconnection, looseness,

deterioration

“Oil Cooler Hoses Replacement”

A/T select cable

Installation, operation

Engine oil

Level, leakage

“Engine Oil and Filter Change in Section 0B”

Engine coolant

Level, leakage

“Engine Coolant Change in Section 0B”

Battery

Fluid level, corrosion of terminal

Connectors of electric wire harness Disconnection friction

“Intermittent and Poor Connection Inspection in

Section 00”

Fuses

Burning

“Cautions in Body Electrical System Servicing in

Section 9A”

Parts

Installation, damage

Bolt

Looseness

Malfunction indicator lamp

Operation at engine start

“Malfunction Indicator Lamp (MIL) Check in

Section 1A”

Charge warning light

Operation at engine start

“Generator Symptom Diagnosis in Section 1J”

Engine oil pressure warning light

Operation at engine start

“Oil Pressure Switch Inspection in Section 9C”

Engine coolant temp. meter

Operation at engine start

Other parts that can be checked visually

Step

Action

Yes

No

1

Was “A/T System Check” performed?

Go to Step 2.

Go to “A/T System

Check”.

2

Perform “Road Test”

Is it OK?

Go to Step 3.

Proceed to

“Troubleshooting” in

“Road Test”.

3

Perform “Manual Road Test”

Is it OK?

Go to Step 4.

Proceed to

“Troubleshooting” in

“Manual Road Test”.

4

Perform “Engine Brake Test”

Is it OK?

Go to Step 5.

Proceed to

“Troubleshooting” in

“Engine Brake Test”.

5

Perform “Stall Test”

Is it OK?

Go to Step 6.

Proceed to

“Troubleshooting” in

“Stall Test”.

6

Perform “Time Lag Test”

Is it OK?

Go to Step 7.

Proceed to

“Troubleshooting” in

“Time Lag Test”.

7

Perform “Line Pressure Test”

Is it OK?

Go to Step 8.

Proceed to

“Troubleshooting” in

“Line Pressure Test”.

8

1) Proceed to “Trouble Diagnosis 1” in “A/T Symptom

Is trouble identified?

Repair or replace faulty

parts.

Go to Step 9.

9

1) Proceed to “Trouble Diagnosis 2” in “A/T Symptom

Is trouble identified?

Repair or replace faulty

parts.

Proceed to “Trouble

Diagnosis 3” in “A/T

Symptom Diagnosis”.