Suzuki Grand Vitara JB416 / JB420. Manual - part 296

7B-75 Air Conditioning System:

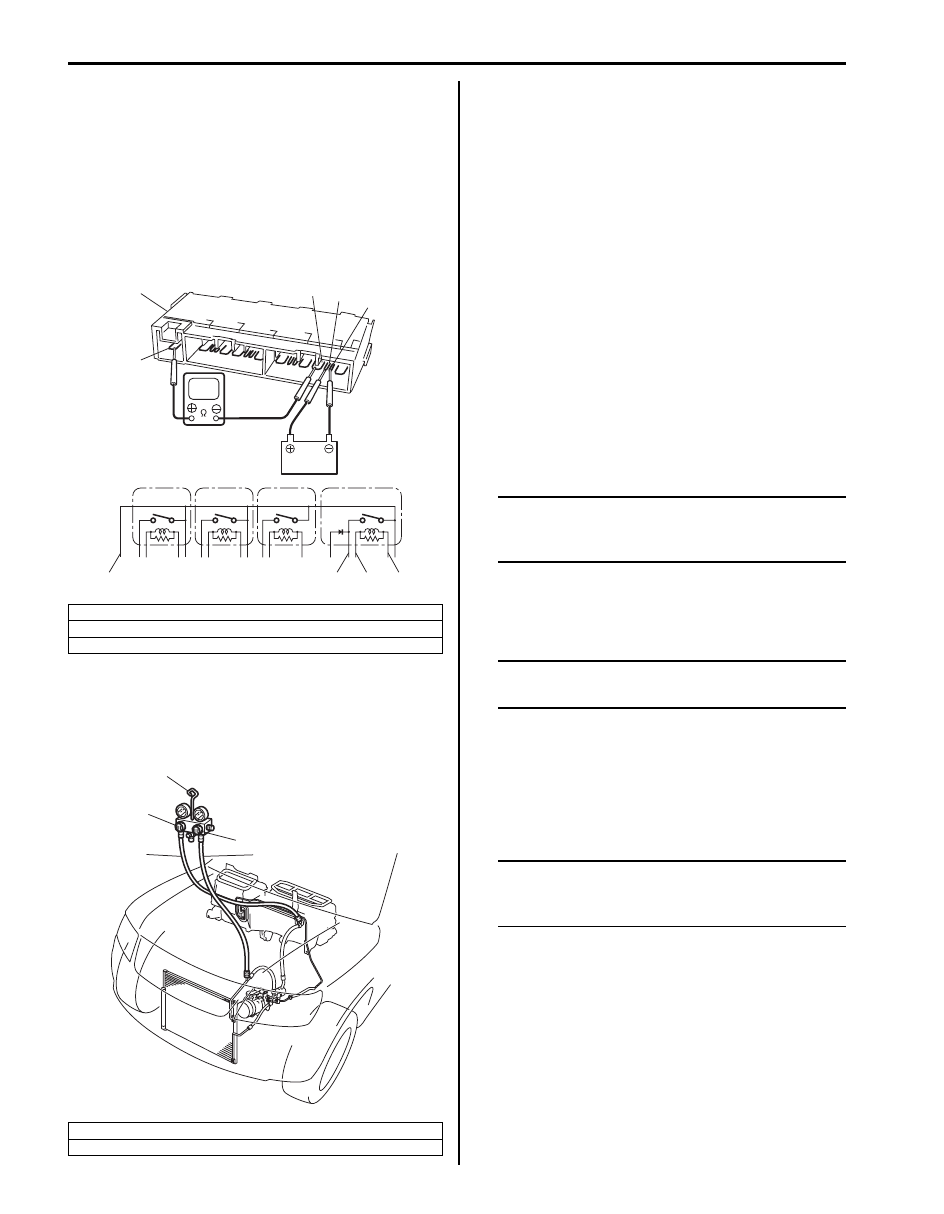

3) Check that there is no continuity between terminals

“C” and “D”.

If there is continuity, replace integration relay No.2

(1).

4) Connect battery positive (+) terminal to terminal “B”

of relay. Connect battery negative (–) terminal to

terminal “A” of relay. Check for continuity between

terminal “C” and “D”. If there is no continuity when

relay is connected to the battery, replace integration

relay No.2 (1).

Compressor Assembly On-Vehicle Inspection

S5JB0A7206041

1) Install manifold gauge set (1) as shown in the figure.

2) Close Hi (4) and Lo (5) side valves.

3) Run engine at fast idle.

4) Check compressor for the following items.

If any of the checks indicated a defect, repair

compressor.

• High pressure gauge reading is not low and low

pressure gauge reading is not higher than normal.

• Metallic sound

• Leakage from compressor

Compressor Assembly Removal and

Installation for M16 Engine Model

S5JB0A7206042

Removal

1) Run engine at idle with A/C ON for 10 minutes.

2) Disconnect negative (–) cable at battery.

3) Recover refrigerant from the A/C system using

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Charging A/

C with Refrigerant”.

NOTE

The amount of compressor at removed must

be measured and the same amount must be

poured when installing the compressor.

4) Disconnect thermal protector lead wire.

5) Disconnect suction and discharge hoses from

compressor.

NOTE

Cap open fitting immediately to keep

moisture out of system.

6) Remove compressor drive belt referring to “P/S

7) Remove compressor with clutch assembly from its

mount.

NOTE

If compressor assembly is replaced with one,

drain oil from compressor. Then, measure its

amount.

[A]: A/T relay

[B]: HO2S heater relay

[C]: Compressor relay

2. High pressure side (Delivery side hose)

3. Low pressure side (Suction side pipe)

“D”

“C”

[A]

[B]

[C]

1

“B”

“A”

“C”

“D”

“B”

“A”

I5JB0A720058-01

1

5

3

4

2

I5JB0A720059-01