Suzuki Grand Vitara JB416 / JB420. Manual - part 245

5A-114 Automatic Transmission/Transaxle:

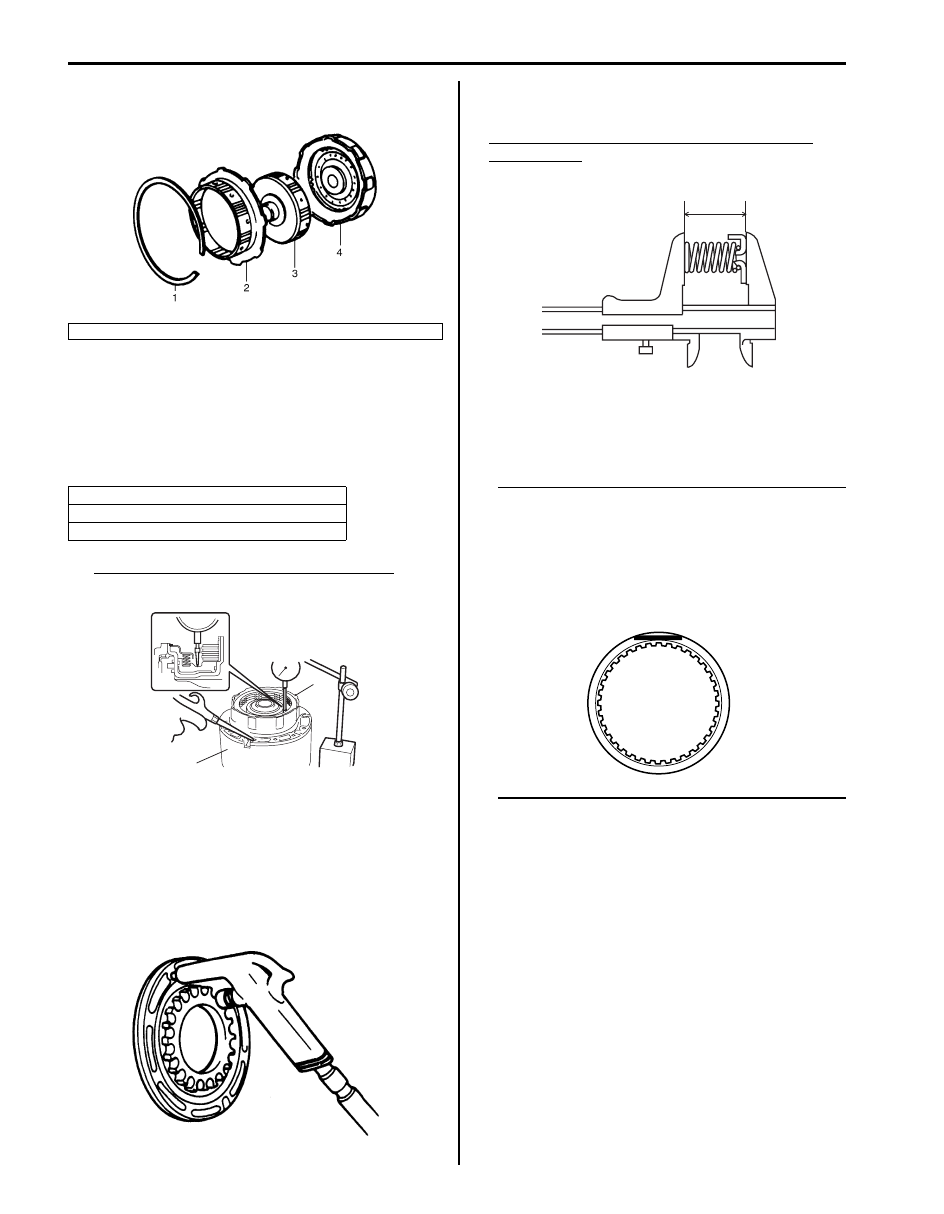

4) Install forward clutch hub (3), direct clutch hub (2)

and retaining ring (1) in that order.

5) Install forward clutch (2) to O/D case (1). Apply

compressed air (400 – 800 kPa, 4 – 8 kg/cm

2

, 57 –

113 psi) to oil hole at the right of cut in O/D case and

measure movement of forward clutch piston.

If measured value is not within standard range,

select another plate with suitable thickness from the

list below and replace it.

Standard forward clutch piston movement

1.40 – 1.70 mm (0.055 – 0.067 in.)

Forward Clutch Inspection

S5JB0A5106079

Forward Clutch Piston

• Shake piston to check that ball is not stuck.

• Blow low pressure air to check ball section for

leakage.

Forward Clutch Piston Return Spring

• Measure free length.

Standard free length of forward clutch piston

return spring

24.81 mm (0.977 in.)

Clutch Plate and Disc

• Check that sliding surface of discs and plate are not

worn or burnt. If necessary, replace them.

NOTE

• If disc lining is exfoliated, discolored or

worn hardly, replace all discs.

• If only a part of printed numbers is

corroded, replace all discs.

• Before assembling new discs, soak them

in A/T fluid for at least 15 minutes.

4. Input shaft

Thickness

1.75 – 1.85 mm (0.069 – 0.073 in.)

1.95 – 2.05 mm (0.077 – 0.081 in.)

IYSQ01510151-01

2

1

I5JB0A510150-01

IYSQ01510152-01

I5JB0A510171-01

I4JA01512210-01