Suzuki Grand Vitara JB416 / JB420. Manual - part 150

2C-6 Rear Suspension:

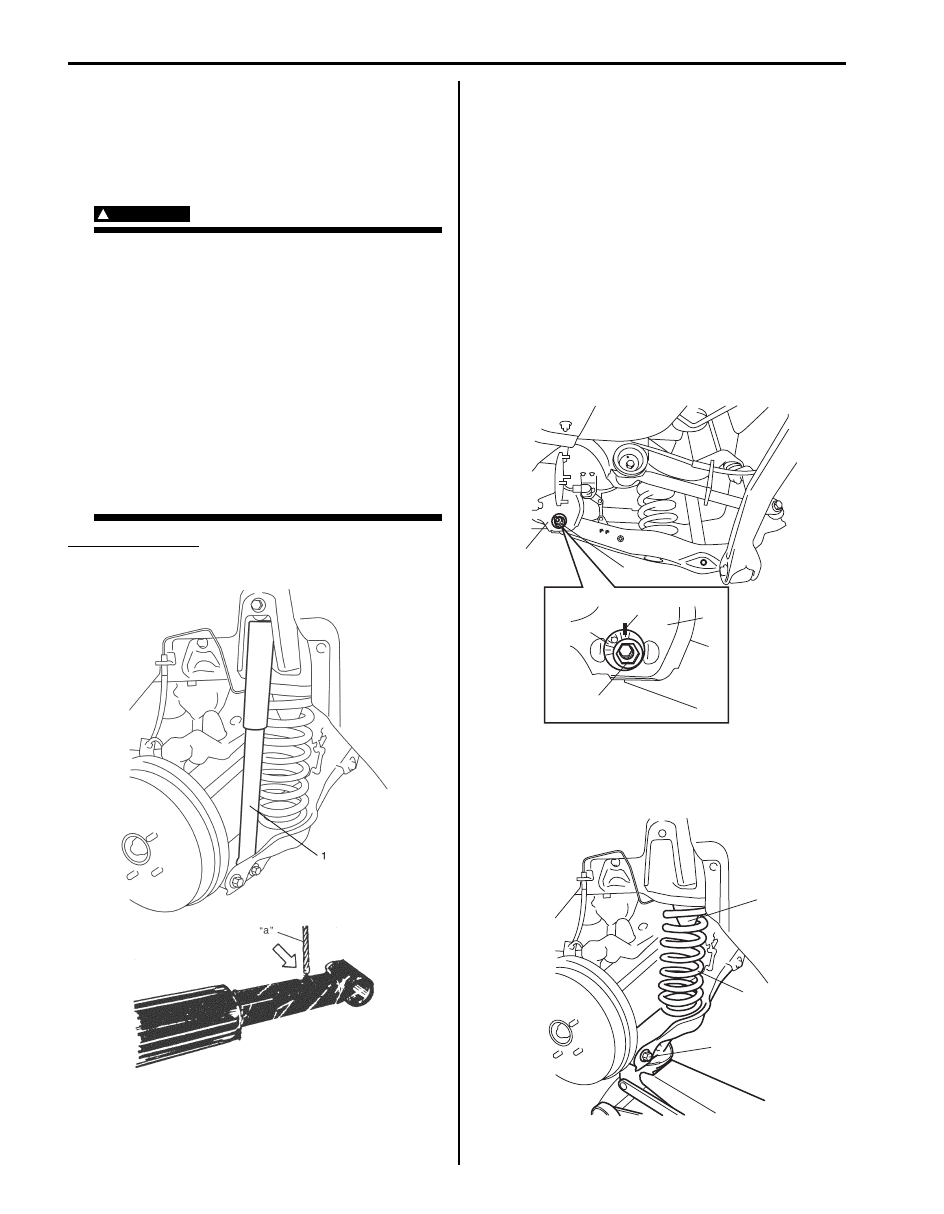

Shock Absorber Check

S5JB0A2306026

• Inspect for deformation or damage.

• Inspect bushings for wear or damage.

• Inspect for evidence of oil leakage.

Replace any defective part.

WARNING

!

When handling rear shock absorber (1) in

which high-pressure gas is sealed, make

sure to observe the following precautions.

• Don’t disassemble it.

• Don’t put it into the fire.

• Don’t store it where it gets hot.

• Before disposing it, be sure to drill a hole

in it where shown by an arrow in the figure

and let gas and oil out. Lay it down

sideways for this work.

• The gas itself is harmless but it may issue

out of the hole together with chips

generated by the drill. Therefore, be sure

to wear goggle.

Drill hole diameter

“a”: Approx. 3 mm (0.12 in.)

Rear Coil Spring and Bump Stopper Removal

and Installation

S5JB0A2306027

Removal

1) Hoist vehicle, allowing rear suspension to hang free.

2) Remove rear wheels.

3) Disconnect rear height sensor link (if equipped) from

lower arm for left side referring to “Height Sensor

Removal and Installation (If Equipped) in Section

9B”.

4) Remove rear shock absorber referring to “Rear

Shock Absorber Removal and Installation”.

5) Put match marks (1) on lower arm washer (2) and on

suspension frame (3) to install the bolts correctly in

position.

6) Loosen lower arm mount nut (4).

7) Remove lower arm outer bolt (1).

8) Lower jack and then remove rear coil spring (2) and

coil spring rubber seat (3).

I5JB0A230011-01

1

2

3

3

4

4

I5JB0A230010-01

3

2

1

I5JB0A230012-01