Suzuki Grand Vitara JB416 / JB420. Manual - part 128

1G-14 Fuel System:

iii) Turn ignition switch ON.

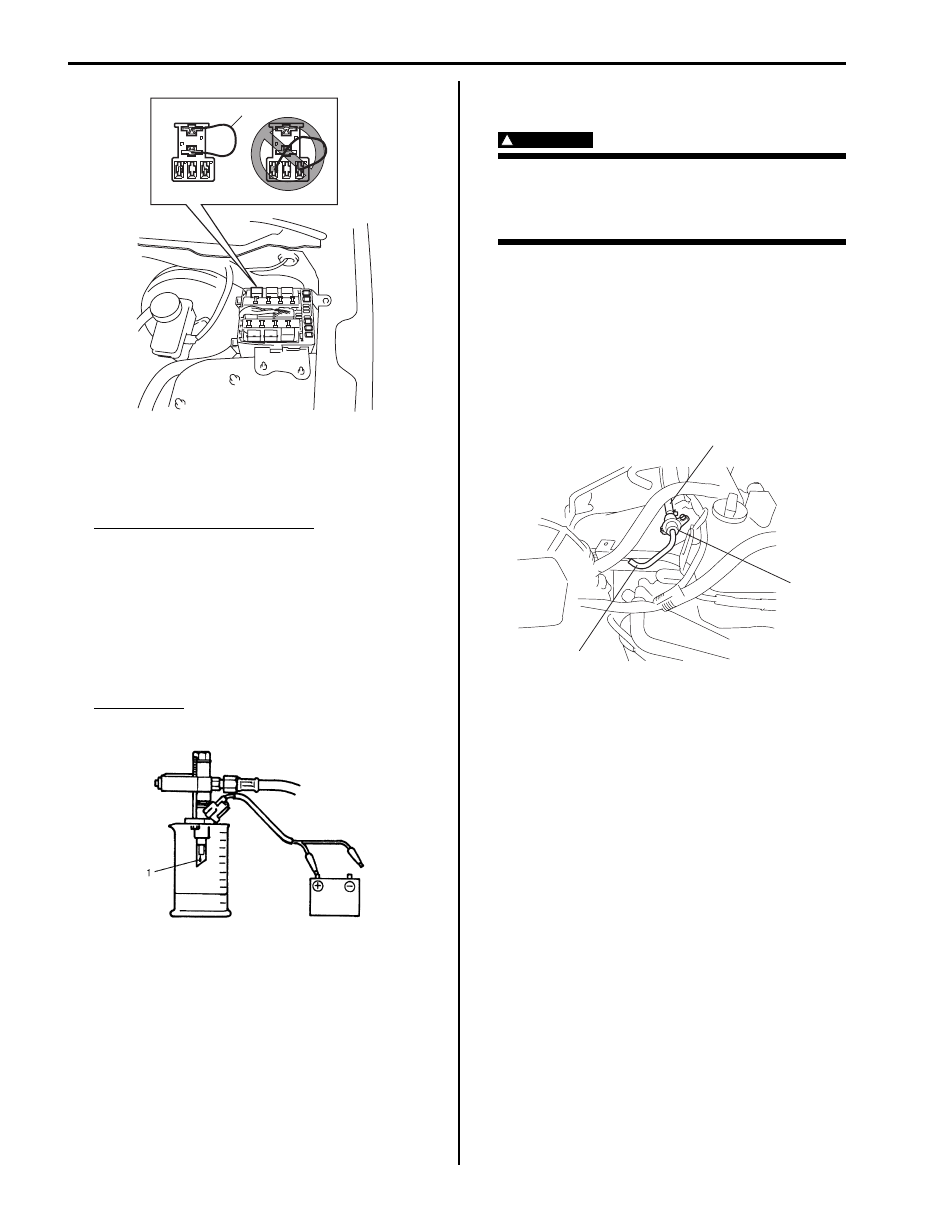

8) Apply battery voltage to injector (1) for 15 seconds

and measure injected fuel volume with graduated

cylinder. Test each injector two or three times.

Reference injected fuel volume

(For M16 engine model) Approx. 46 cc / 15 sec.

(1.62/1.55 US/Imp oz / 15 sec.)

(For J20 engine model) Approx. 65 cc / 15 sec.

(2.20/2.29 US/Imp oz / 15 sec.)

9) Check fuel leakage from injector nozzle. Do not

operate injector for this check (but fuel pump should

be at work). If fuel leaks (1) more than the following

specifications, replace.

Fuel leakage

Less than 1 drop/min.

Fuel Pressure Regulator Removal and

Installation

S5JB0A1706024

WARNING

!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service”in order to reduce the risk or fire and

personal injury.

Removal

1) Relieve fuel pressure according to “Fuel Pressure

2) Disconnect negative cable at battery.

3) Disconnect fuel return hose (1) and vacuum hose (2)

from fuel pressure regulator.

4) Remove fuel pressure regulator (3) from delivery

pipe.

1

I5JB0A171010-02

I2RH0B170013-01

1

2

3

I5JB0A171011-02