Suzuki Grand Vitara JB416 / JB420. Manual - part 114

1D-124 Engine Mechanical: For J20 Engine

Out-of-round and taper (uneven wear) of journals

An unevenly worn crankshaft journal shows up as a

difference in diameter at a cross section or along its

length (or both). This difference, if any, is determined by

taking micrometer readings. If any one of journals is

badly damaged or if amount of uneven wear in the sense

exceeds its limit, regrind or replace crankshaft.

Limit on out-of-round and taper

0.01 mm (0.0004 in.)

Out-of-round

“A” – “B”

Taper

“a” – “b”

Main Bearings

Main bearings general information

• Service main bearings are available in standard size

and 0.25 mm (0.0098 in.) undersize, and standard

size has 5 kinds of bearings differing in tolerance.

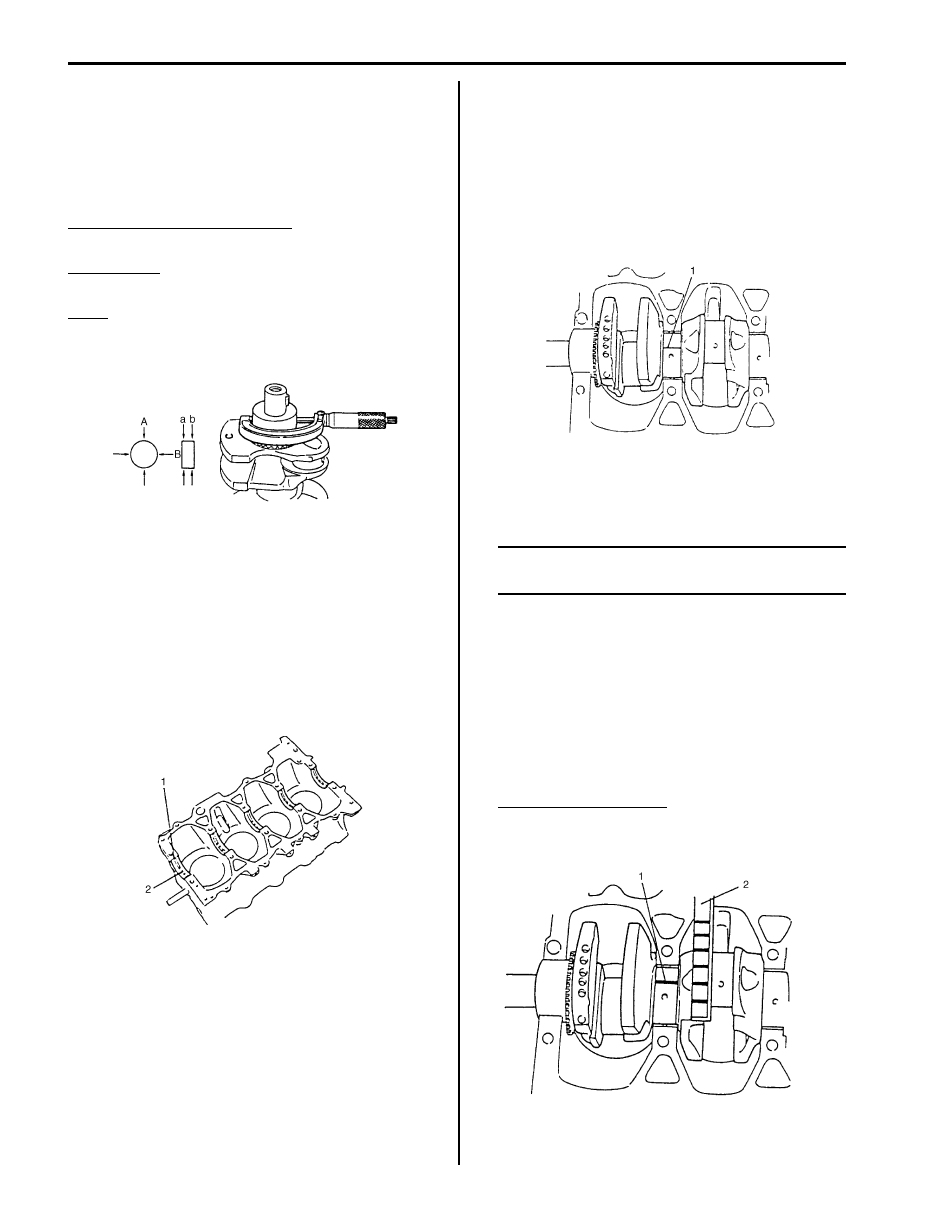

• Upper half of bearing (1) has oil groove (2) as shown

in figure.

Install this half with oil groove to cylinder block.

• Lower half of bearing does not have oil groove.

Main bearings inspection

Check bearings for pitting, scratches, wear or damage.

If any malcondition is found, replace both upper and

lower halves. Never replace either half without replacing

the other half.

Main bearing clearance

Check clearance by using gauging plastic according to

the following procedure.

1) Remove lower crankcase.

2) Clean bearings and main journals.

3) Place a piece of gauging plastic (1) to full width of

bearing (parallel to crankshaft) on journal, avoiding

oil hole.

4) Install lower crankcase to cylinder block referring to

“Main Bearings, Crankshaft and Cylinder Block

Removal and Installation: For J20 Engine”.

NOTE

Do not rotate crankshaft while gauging

plastic is installed.

5) Remove lower crankcase and using scale (2) on

gauging plastic envelop (1), measure gauging plastic

width at its widest point. If clearance exceeds its

limit, replace bearing. Always replace both upper

and lower inserts as a unit.

A new standard bearing may produce proper

clearance. If not, it will be necessary to regrind

crankshaft journal for use of 0.25 mm undersize

bearing.

After selecting new bearing, recheck clearance.

Main Bearing Clearance

Standard: 0.032 – 0.050 mm (0.0013 – 0.0019 in.)

Limit: 0.063 mm (0.0024 in.)

I2RH01140185-01

I2RH01140186-01

I2RH01140187-01

I2RH01140188-01