Suzuki Grand Vitara JB416 / JB420. Manual - part 111

1D-112 Engine Mechanical: For J20 Engine

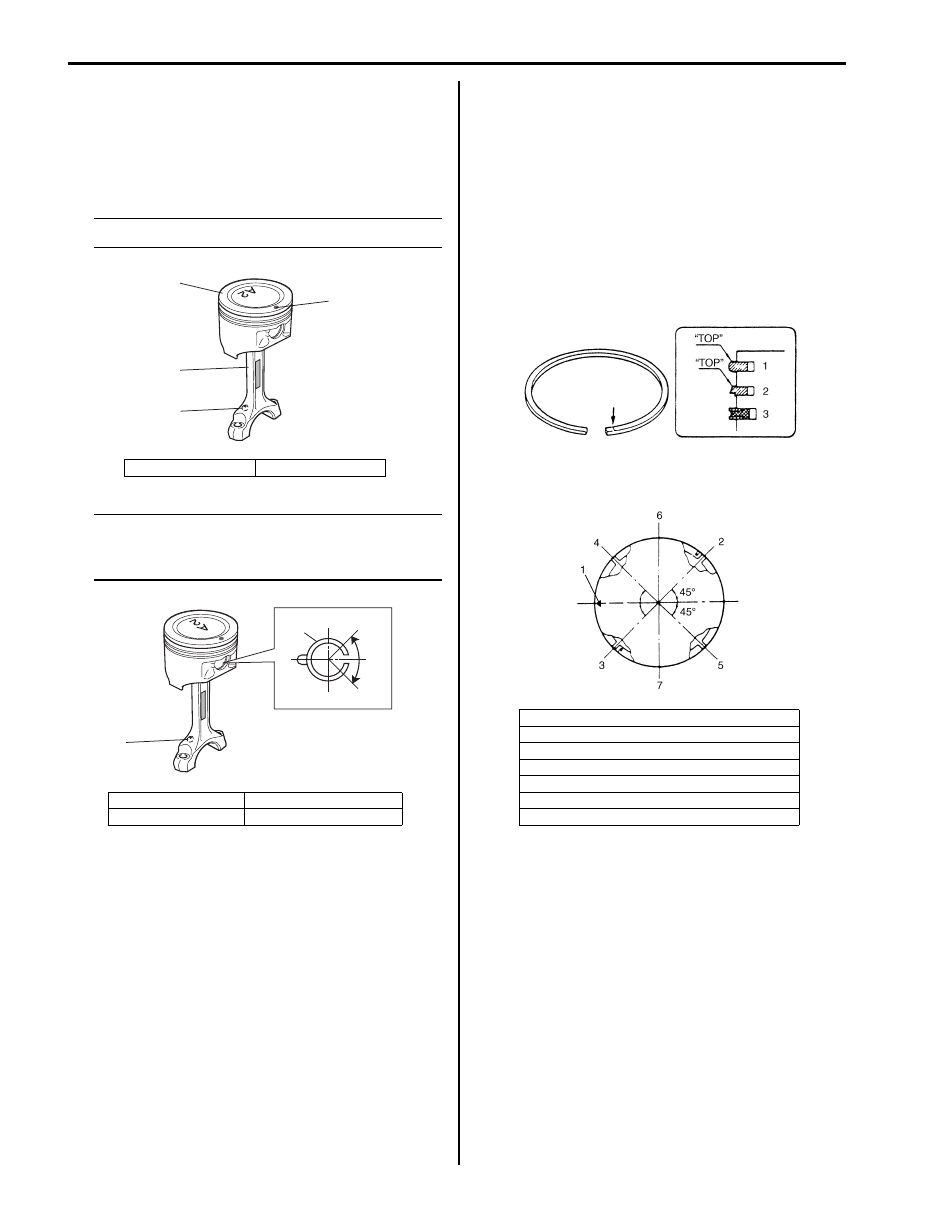

4) Install piston pin to piston (1) and connecting rod (3):

After applying engine oil to piston pin and piston pin

holes in piston and connecting rod, fit connecting rod

to piston as shown in figure and insert piston pin to

piston and connecting rod, and install piston pin

circlips.

NOTE

Oil hole (4) come on intake side.

NOTE

Circlip (4) should be installed so that circlip

end gap comes within such range as

indicated by arrow.

5) Install piston rings to piston:

• As indicated in figure at the left, 1st and 2nd rings

have “TOP” mark respectively. When installing

these piston rings to piston, direct marked side of

each ring toward top of piston.

• 1st ring (1) differs from 2nd ring (2) in thickness,

shape and color of surface contacting cylinder

wall.

Distinguish 1st ring from 2nd ring by referring to

figure.

• When installing oil ring (3), install spacer first and

then two rails.

6) After installing three rings (1st, 2nd and oil rings),

distribute their end gaps as shown in figure.

2. Front mark

4. Oil hole

1. Piston

3. Connecting rod

2. Front mark

5. Oil hole

1

2

3

4

I5JB0A142051-01

4

5

I4RH01140039-01

1. Front mark

2. 1st ring end gap

3. 2nd ring end gap and oil ring spacer gap

4. Oil ring upper rail gap

5. Oil ring lower rail gap

6. Intake side

7. Exhaust side

I5JB0A142052-02

I5JB0A142053-01