Suzuki Grand Vitara JB416 / JB420. Manual - part 95

1D-48 Engine Mechanical: For M16A Engine with VVT

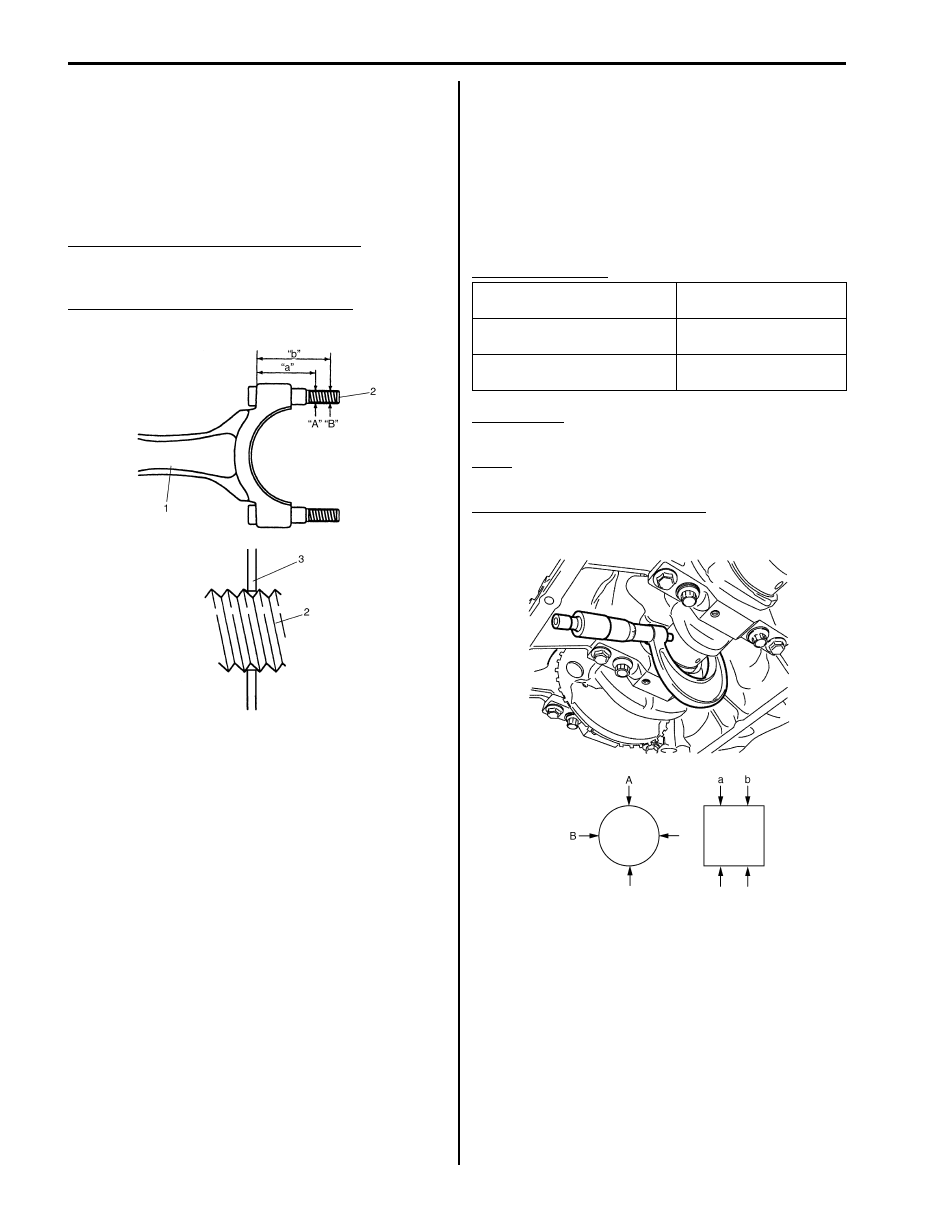

Connecting rod bolt deformation (Plastic

deformation tightening bolt)

Measure each thread diameter of connecting rod bolt (2)

at “A” on 32 mm (1.25 in.) from bolt mounting surface

and “B” on 40 mm (1.57 in.) from bolt mounting surface

by using a micrometer (3).

Calculate difference in diameters (“A” – “B”). If it is

exceeds limit, replace connected rod (1).

Connecting rod bolt measurement points

“a”: 32 mm (1.25 in.)

“b”: 40 mm (1.57 in.)

Connecting rod bolt diameter difference

Limit (“A” – “B”): 0.1 mm (0.004 in.)

Crank Pin and Connecting Rod Bearings

Inspection

S5JB0A1416034

Crank Pin Diameter

Inspect crank pin for uneven wear or damage. Measure

crank pin for out-of-round or taper with a micrometer. If

crank pin is damaged or out-of round or taper is out of

limit, replace crankshaft or regrind crank pin to undersize

and use undersize bearing.

Crank pin diameter

Out-of-round

A – B

Taper

a – b

Crank pin taper and out-of-round

Limit: 0.01 mm (0.0004 in.)

I2RH0B140119-01

Connecting rod bearing

size

Crank pin diameter

Standard

41.982 – 42.000 mm

(1.6528 – 1.6535 in.)

0.25 mm (0.0098 in.)

undersize

41.732 – 41.750 mm

(1.6430 – 1.6437 in.)

I2RH0B140120-01