Suzuki Grand Vitara JB416 / JB420. Manual - part 84

1D-4 Engine Mechanical: For M16A Engine with VVT

Targeted Timing Varying Operation

Diagnostic Information and Procedures

Compression Check

S5JB0A1414001

Check compression pressure on all 4 cylinders as

follows:

1) Warm up engine to normal operating temperature.

2) Stop engine after warming up.

NOTE

After warming up engine, place transaxle

gear shift lever in “Neutral”, and set parking

brake and block drive wheels.

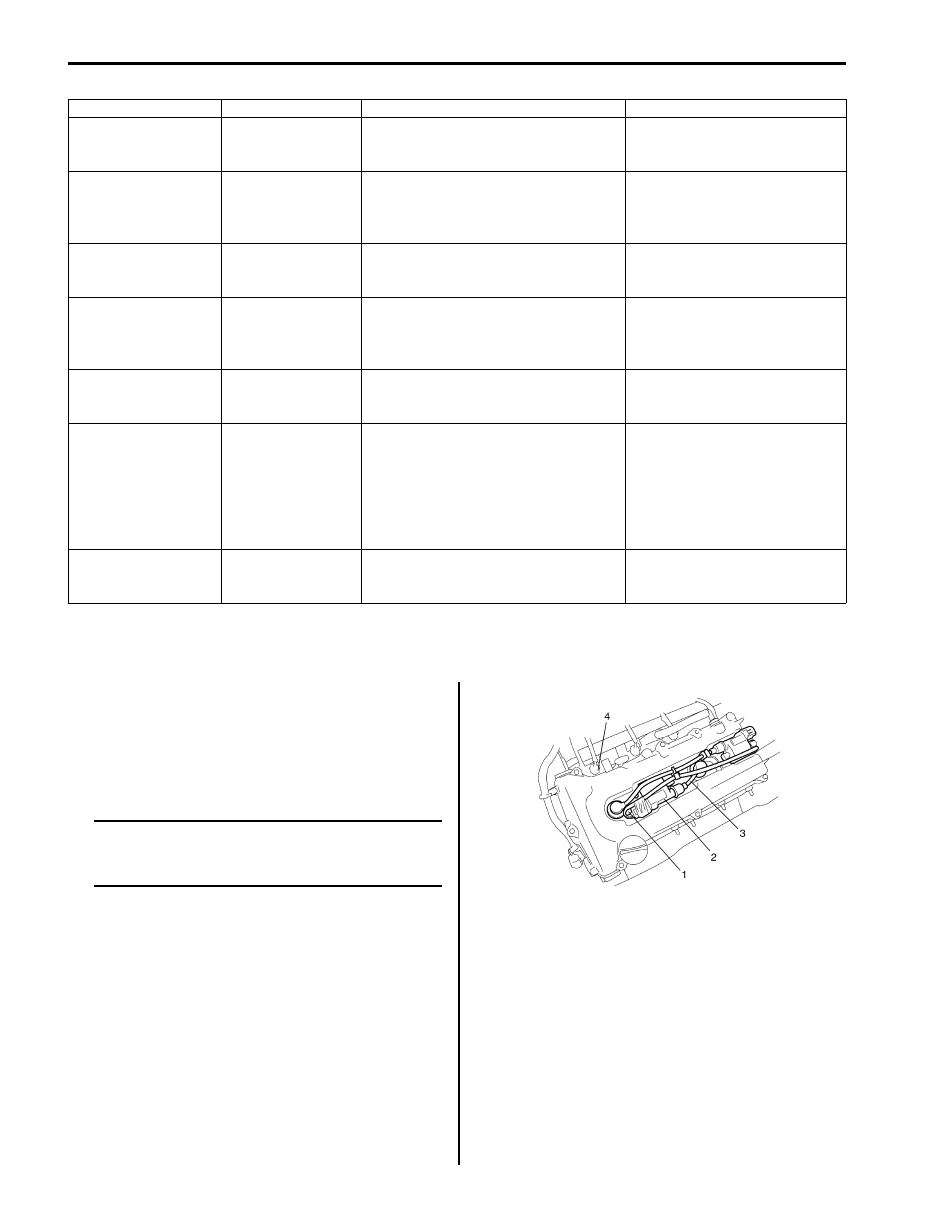

3) Disconnect ignition coil couplers (1).

4) Remove ignition coil assemblies (2) with high-

tension cord (3).

5) Remove all spark plugs.

6) Disconnect fuel injector wires (4) at the coupler.

Driving condition

Valve timing

Target of control

Effect

Engine running at idle

speed

Most retarded

To shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold.

Stabilization of the engine

rotation at idle speed.

Average engine load

range

To the advanced

side

To lengthen the valve opening overlap

in order to enhance the internal

exhaust gas recirculation and reduce

the pumping loss.

Improvement of the fuel

efficiency.

Lowering of the exhaust

emission.

Light engine load

range

To the retarded side

To shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold.

Keeping of the engine stability.

Low or average

engine speed range

with heavy engine

load

To the advanced

side

To advance the closing timing of the

intake valve in order to improve the

volumetric efficiency.

Improvement of generating the

engine torque at low and

average engine speed.

High engine speed

range with heavy

engine load

To the retarded side

To retard the closing timing of the

intake valve in order to improve the

volumetric efficiency.

Improvement of generating the

engine power.

Low engine coolant

temperature

Most retarded

To shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold and

reduce the fuel increasing.

To slow the fast idle speed of the

engine as a result of stabilizing the

engine idling.

Stabilization of the fast idling of

the engine.

Improvement of the fuel

efficiency.

At engine starting and

stopping

Most retarded

To shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold.

Improvement of start ability.

I2RH0B140003-01