Suzuki Grand Vitara JB416 / JB420. Manual - part 51

1A-153 Engine General Information and Diagnosis:

DTC P0504: Brake Switch “A”/“B” Correlation (For J20 Engine)

S5JB0A1104096

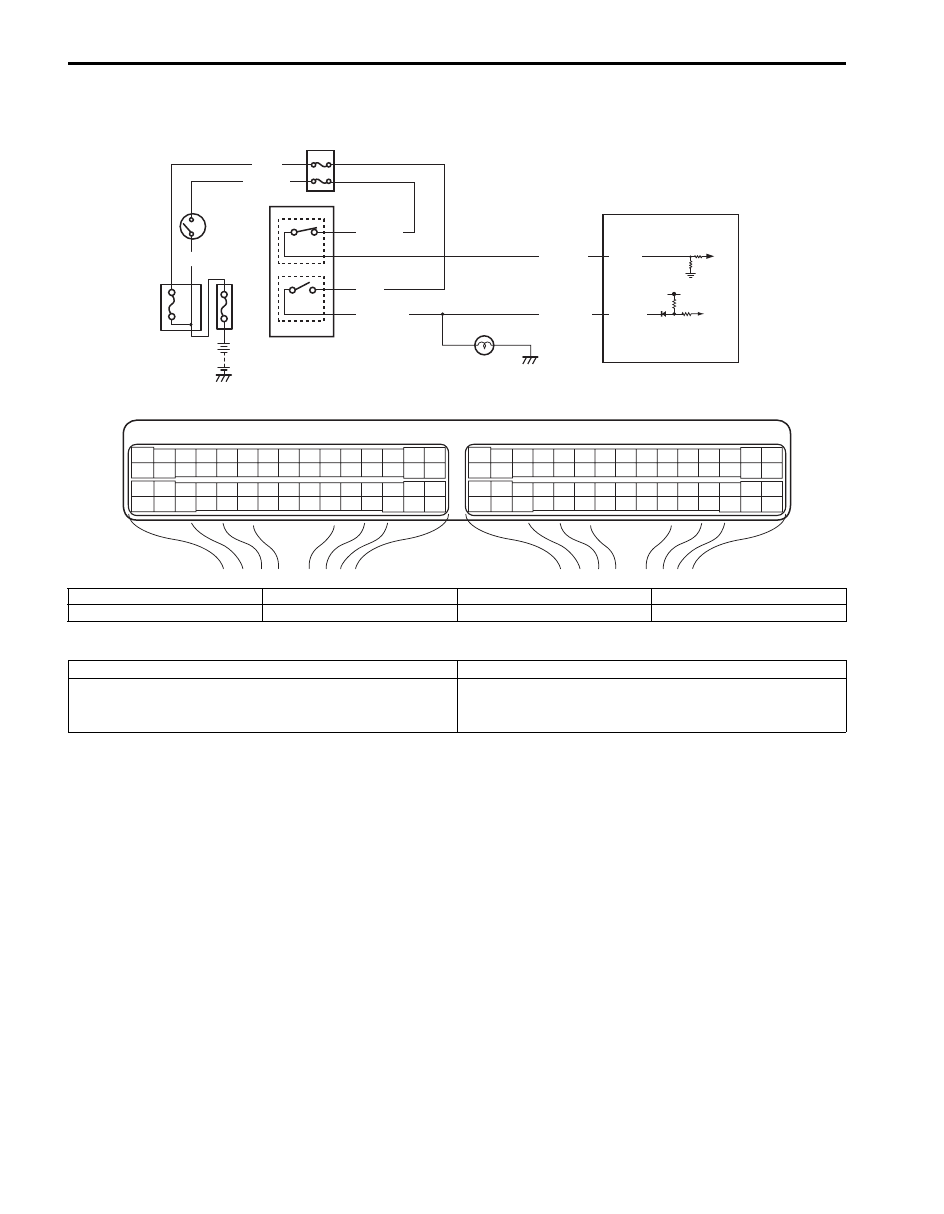

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool to DLC.

2) Turn ON ignition switch and clear DTC.

3) Start engine and warm up to normal operating temperature. (ECT approx. 90 – 95

°C, 194 – 203 °F)

4) Drive vehicle at 50 km/h (80 mph) or higher for 3 min. or more.

5) Stop vehicle.

6) Depress brake pedal for 3 times.

7) Check DTC and pending DTC.

E23

C37

3

4

18

19

5

6

7

10

11

17

20

47

46

49

50

51

21

22

52

16

25

9

24

14

29

55

57

54 53

59

60

58

2

26

27

28

15

30

56

48

32

31

34

35

36

37

40

42

39 38

44

45

43

41

33

1

12

13

23

8

3

4

18

19

5

6

7

10

11

17

20

47

46

49

50

51

21

22

52

16

25

9

24

14

29

55

57

54 53

59

60

58

2

26

27

28

15

30

56

48

32

31

34

35

36

37

40

42

39 38

44

45

43

41

33

1

12

13

23

8

BLK/YEL

WHT/GRN

GRN/WHT

E23-20

GRN/WHT

GRN

12V

E23-8

BLU/BLK

WHT

YEL/GRN

1

3

2

4

5

6

7

I5JB0A110107-02

1. Stop lamp (brake pedal) switch

3. Brake pedal switch

5. Stop lamp

7. “STOP” fuse

2. Stop lamp switch

4. ECM

6. “CRUISE” fuse

DTC detecting condition

Trouble area

Brake pedal switch signal is inconsistent with stop lamp

switch signal.

(1 driving cycle detection logic but MIL does not light up)

• Stop lamp (brake pedal) switch and/or its circuit

• ECM