содержание .. 37 38 39 40 ..

Peugeot 205. Manual - part 39

mounting in a vice and attempting to extend

and retract it. If the resistance is not firm and

even in both directions, or if there are signs of

leakage or damage, the shock absorber must

be renewed.

Refitting

6 Refitting is a reversal of removal, but renew

the self-locking nuts. The nuts must be

tightened when the distance between the

mounting bolt centres is 288.0 mm. The

Peugeot tool 80911 for this operation consists

of a bar and adjustable bolt located beneath

the lifting ramp and hooked on the suspension

tube; however, loading the rear of the car by

trial and error will produce the same result.

11 Rear suspension assembly -

removal and refitting

4

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and vehicle support”).

2 Remove the handbrake cables, with

reference to Chapter 9.

3 Remove the complete exhaust system, with

reference to Chapter 4D.

4 Disconnect the flexible brake hoses from

the rear suspension assembly, with reference

to Chapter 9.

5 Unscrew the left-hand rear mounting nut,

remove the exhaust bracket then temporarily

refit the nut.

6 Unbolt and remove the front clamp and

bracket (see illustration), but do not unscrew

the seat belt anchorage (where fitted).

7 Adjust the position of the car on the axle

stands so that the rear wheels are just

touching the ground, then place additional

stands or jacks beneath the suspension tube.

8 Working in the luggage compartment

unscrew the front and rear mounting nuts then

carefully withdraw the assembly from under

the car.

Refitting

9 Refitting is a reversal of removal, but tighten

all nuts and bolts to the specified torque.

When tightening the front clamp make sure

that the ring is centred in the seat belt

anchorage bracket. Refer to Chapter 4D and 9

when refitting disturbed exhaust and braking

system components and bleed the brake

hydraulic system on completion.

12 Vehicle ride height - checking

5

Checking of the vehicle ride height requires

the use of Peugeot special tools to accurately

compress the suspension in a suspension

checking bay.

The operation should be entrusted to a

Peugeot dealer, as it not possible to carry out

checking accurately without the use of the

appropriate tools.

13 Steering wheel - removal and

refitting

2

Removal

1 Set the front wheels in the straight-ahead

position.

2 Prise out the centre pad, then use a socket

to unscrew the retaining nut (see illustration).

3 Mark the hub in relation to the inner column

then pull off the steering wheel.

Refitting

4 Refitting is a reversal of removal, but check

that the steering wheel is correctly centred

with the front wheels straight ahead. Tighten

the nut while holding the steering wheel rim.

14 Steering column and lock -

removal and refitting

4

Removal

1 Remove the steering wheel, (Section 13).

2 Remove the lower trim panel from under the

steering column (see illustration).

3 Mark the column lower universal joint in

relation to the intermediate shaft then

unscrew and remove the clamp bolt (see

illustration).

4 Remove the combination switches, as

described in Chapter 12.

5 Disconnect the ignition switch wiring

connectors.

6 Unscrew the mounting nuts and bolts,

disconnect the inner column from the

intermediate shaft, and withdraw the steering

column from the car. Where shear bolts are

fitted they must be drilled to remove the

heads, then unscrewed after removing the

column.

Suspension and steering 10•7

10

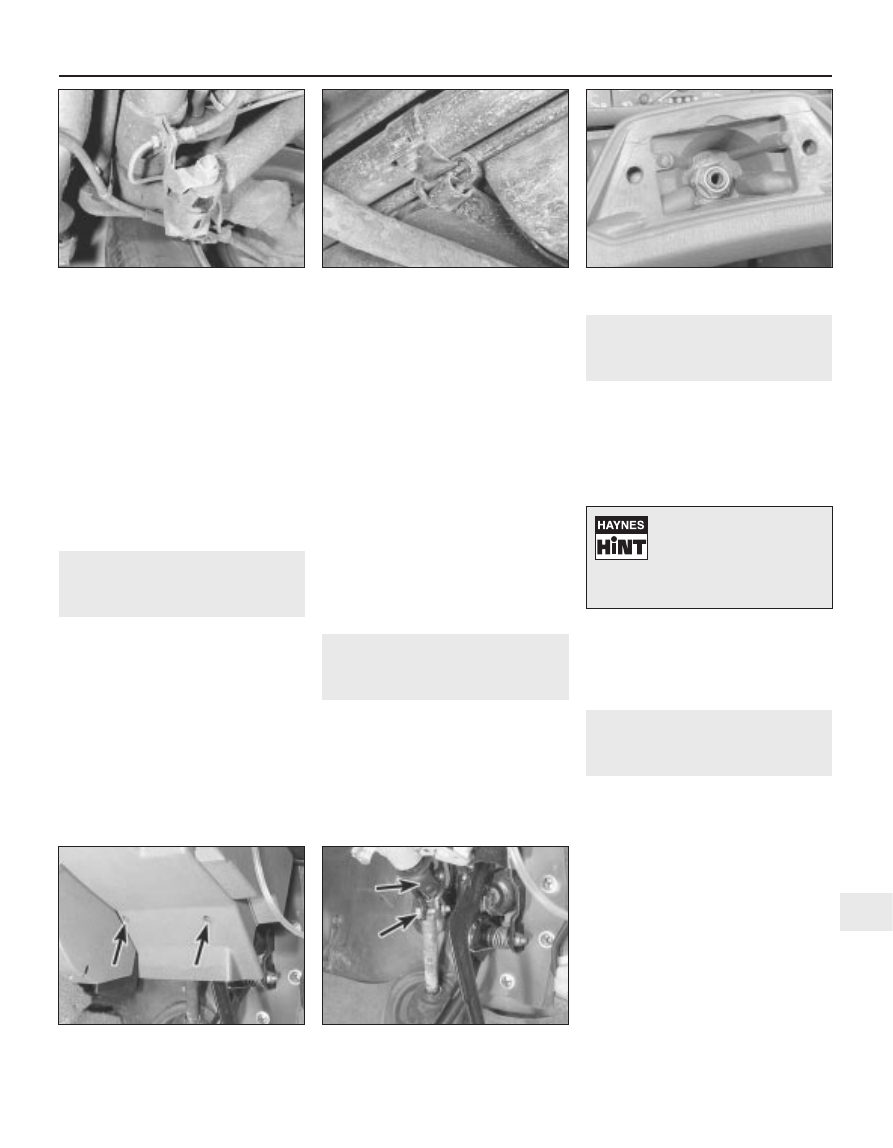

10.2 Rear shock absorber bottom

mounting

11.6 Rear suspension cross-tube front

clamp and seat belt anchorage

13.2 Steering wheel retaining nut

14.2 Steering column lower trim panel

screws (arrowed)

14.3 Steering column lower universal joint

and clamp bolt (arrowed)

If the wheel is tight, tap it up

near the centre, using the

palm of your hand, or twist it

from side to side, whilst

pulling upwards to release it from the

shaft splines.