содержание .. 5 6 7 8 ..

Peugeot 205. Manual - part 7

24 Using a very thin screwdriver blade, turn

the lock on the chain tensioner fully clockwise

to release the slipper (see illustration).

25 Check that the locating dowel is in

position and fit the oil pump with spacer plate.

If the pump driven sprocket is hard to turn,

release the pump mounting bolts and turn the

pump slightly on its locating dowel.

Re-tighten the bolts.

26 Fit the oil pump drivegear to the

crankshaft.

27 Bolt on the timing chain cover using a new

gasket. The bolt nearest the coolant pump

pulley must be located in the cover before

offering it up, otherwise the pulley will prevent

the bolt entering its cover hole (see

illustration). Do not tighten the cover bolts until

the crankshaft pulley has been pushed into

place to centralise the cover. Fit the coolant

hose safety rod under its cover bolts. This rod

prevents the coolant hose being cut by the rim

of the coolant pump pulley should the hose sag.

28 Fit the fuel pump operating rod and fuel

pump with reference to Chapter 4A, if

necessary.

29 Tighten the timing chain cover bolts to the

specified torque and then trim the upper ends

of the gasket flush. Fit the rocker cover using

a new gasket. Do not overtighten the securing

bolts.

30 Tighten the crankshaft pulley nut to the

specified torque, again jamming the flywheel

to prevent the crankshaft rotating.

31 Refit the starter, if removed (Chapter 5A).

32 Refit and tension the auxiliary drivebelt

(Chapter 1).

33 Lower the engine, reconnect the

mounting.

5

Oil pump - removal,

inspection and refitting

3

Removal

1 Carry out the operations described in

Section 4, paragraphs 1 to 10.

Inspection

2 The oil pump gears are exposed once the

spacer plate is removed.

3 Side movement of the gear spindles will

indicate wear in the bushes and the pump

should be renewed complete.

4 Worn or chipped gear teeth must be

rectified by renewal of the gear.

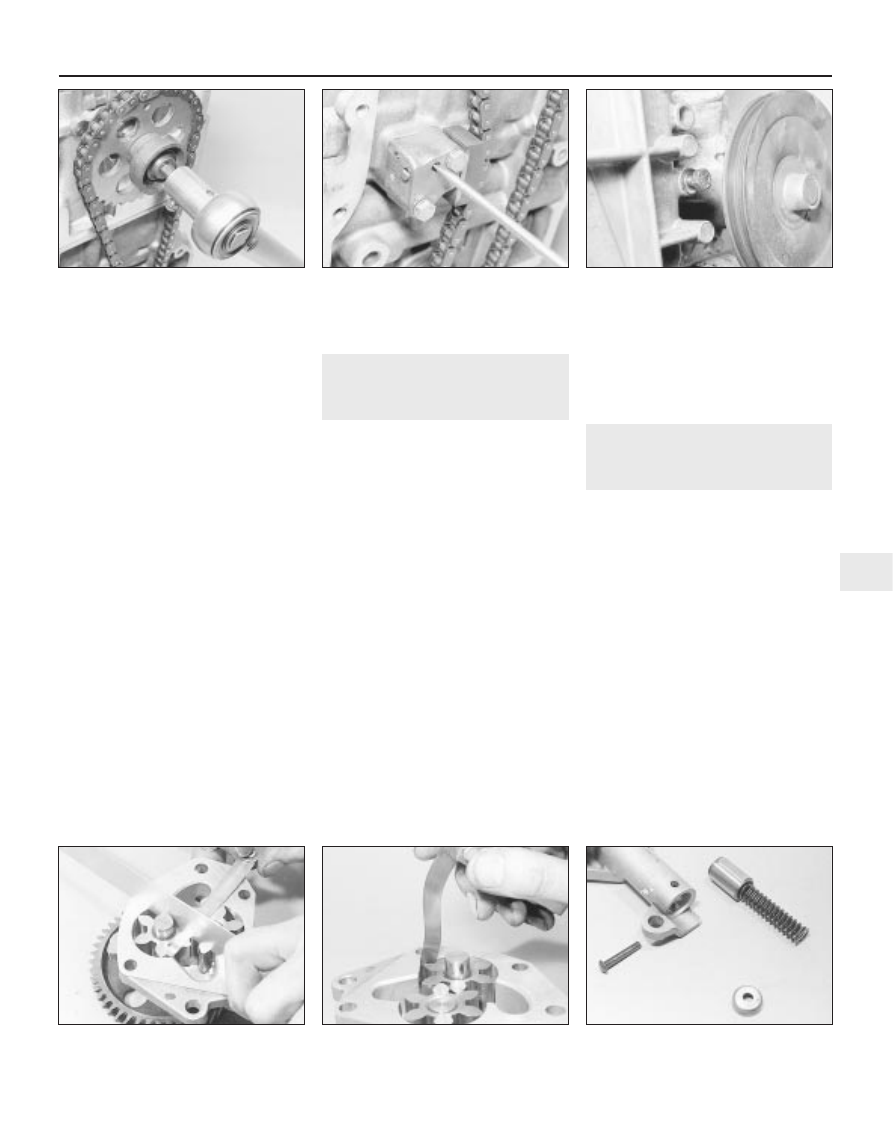

5 Check the endfloat of the gears using a

straight-edge and feeler blades (see

illustration).

6 Check the clearance between the tip of the

gear lobes and the oil pump body (see

illustration).

7 If any of these clearances exceed the

specified limit, renew the pump.

8 Remove the retaining pin from the relief

valve housing and withdraw the cup, spring,

guide and piston. Renew any worn

components

(see illustration).

9 Check that the locating dowel is in position

and fit the oil pump with spacer plate. If the

pump driven sprocket is hard to turn, release

the pump mounting bolts and turn the pump

slightly on its locating dowel. Re-tighten the

bolts.

Refitting

10 Carry out the operations described in

Section 4, paragraphs 24 to 33.

6

Camshaft and rocker arms -

removal, inspection and

refitting

4

General information

1 The rocker arm assembly is secured to the

top of the cylinder head by the cylinder head

bolts. Although in theory it is possible to undo

the head bolts and remove the rocker arm

assembly without removing the head, in

practice, this is not recommended. Once the

bolts have been removed, the head gasket will

be disturbed, and the gasket will almost

certainly leak or blow after refitting. For this

reason, removal of the rocker arm assembly

cannot be done without removing the cylinder

head and renewing the head gasket.

2 The camshaft is slid out of the right-hand

end of the cylinder head, and it therefore

cannot be removed without first removing the

cylinder head, due to a lack of clearance.

Removal

Rocker arm assembly

3 Remove the cylinder head as described in

Section 7.

XV, XW and XY series engine in-car repair procedures 2A•5

2A

4.23 Tightening the camshaft sprocket

retaining bolt

4.24 Releasing the timing chain tensioner

4.27 Timing cover bolt next to coolant

pump pulley in place prior to fitting cover

5.5 Checking oil pump gear endfloat

5.6 Checking oil pump gear to body

clearance

5.8 Oil pump pressure relief valve

components