Opel Frontera UE. Manual - part 797

6E1–71

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

Engine Cranks But Will Not Run

(Cont'd)

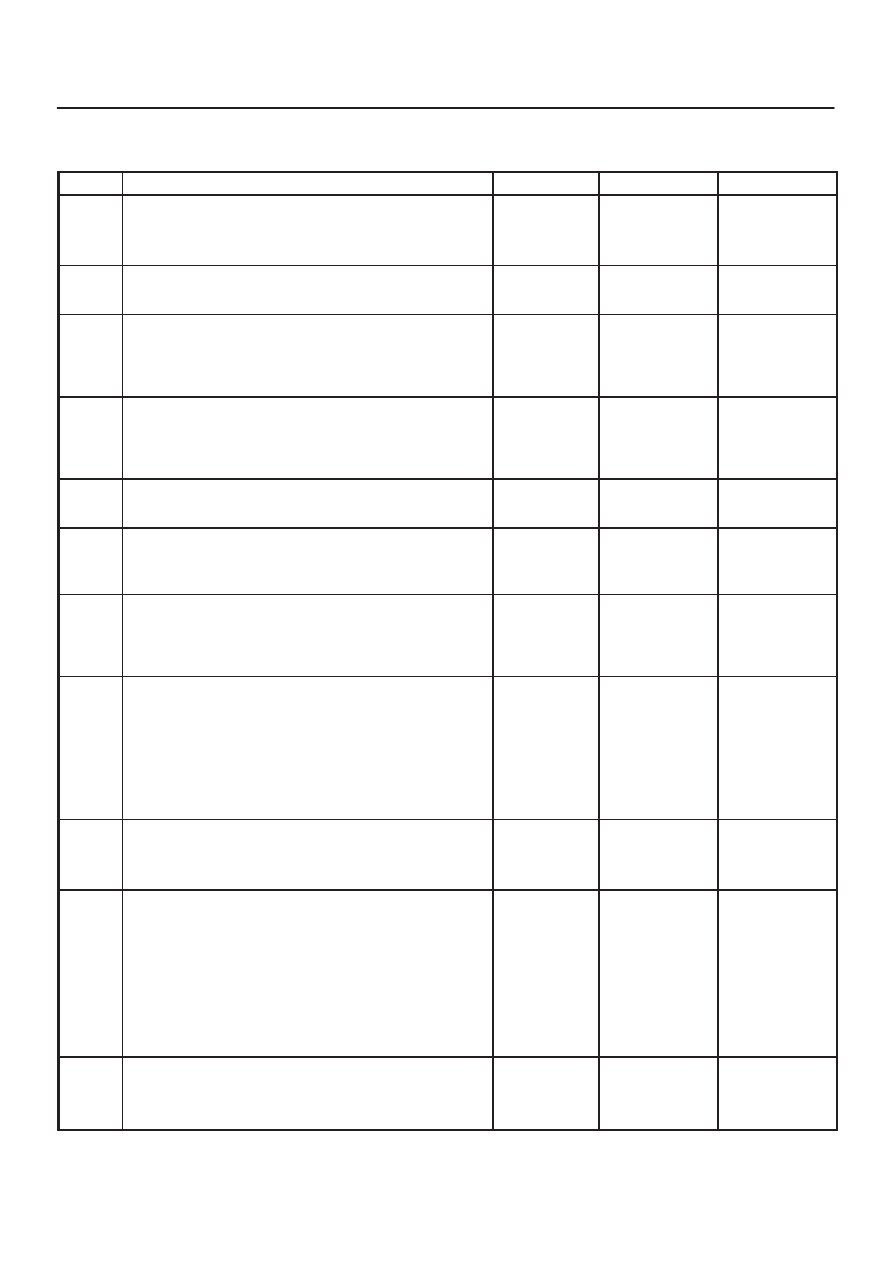

Step

No

Yes

Value(s)

Action

14

Replace the ignition module, verify the repair.

Attempt to start the engine.

Is there still a problem?

—

Go to Step 15

Verify repair

15

Replace the ECM.

Is the action complete?

—

Verify repair

—

16

Use an ohmmeter to check the ignition coil primary

winding resistance.

Was the primary winding resistance approximately

equal to the specified value?

0.8–18

W

Go to Step 17

Go to Step 18

17

Use an ohmmeter to check the ignition coil secondary

winding resistance.

Was the secondary winding resistance equal to the

specified value?

9,000–12,000

W

Go to Step 19

Go to Step 18

18

Replace the ignition coil.

—

Verify repair

—

19

Test the resistance of the coil–to–spark plug secondary

ignition wire.

Was the resistance greater than the specified value?

10,000

W

per

foot

Go to Step 20

Go to Step 21

20

Replace the coil–to–spark plug secondary ignition wire

and any other secondary wires which exceed the

specified value.

Is there still a problem?

10,000

W

per

foot

Go to Step 21

Verify repair

21

1. Remove the spark plugs from all cylinders.

2. Visually inspect the spark plug electrodes.

3. Replace any spark plugs with loose or missing

electrodes or cracked insulators.

Did your inspection reveal any spark plugs exhibiting

excessing fouling?

—

Correct the

fouling

condition

Go to Step 30

22

Verfiy repair.

Attempt to start the engine.

Is there still a problem?

—

Go to Step 23

Go to Step 22

23

1. Ignition OFF, install a fuel pressure gauge at the test

fitting on the fuel supply line in the engine

compartment.

CAUTION: Use a shop cloth to absorb any fuel

leakage while making the connection.

2. Check the engine and observe the fuel pressure.

Is the fuel pressure within the specified values, and

does it hold steady for 2 seconds?

285–375 kPa

(43–55 psi)

Go to Step 25

Go to Step 24

24

Is any fuel pressure indicated?

—

Go to Fuel

System

Electrical Test

Go to Fuel

System

Diagnosis