Opel Frontera UE. Manual - part 235

6E1–238

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

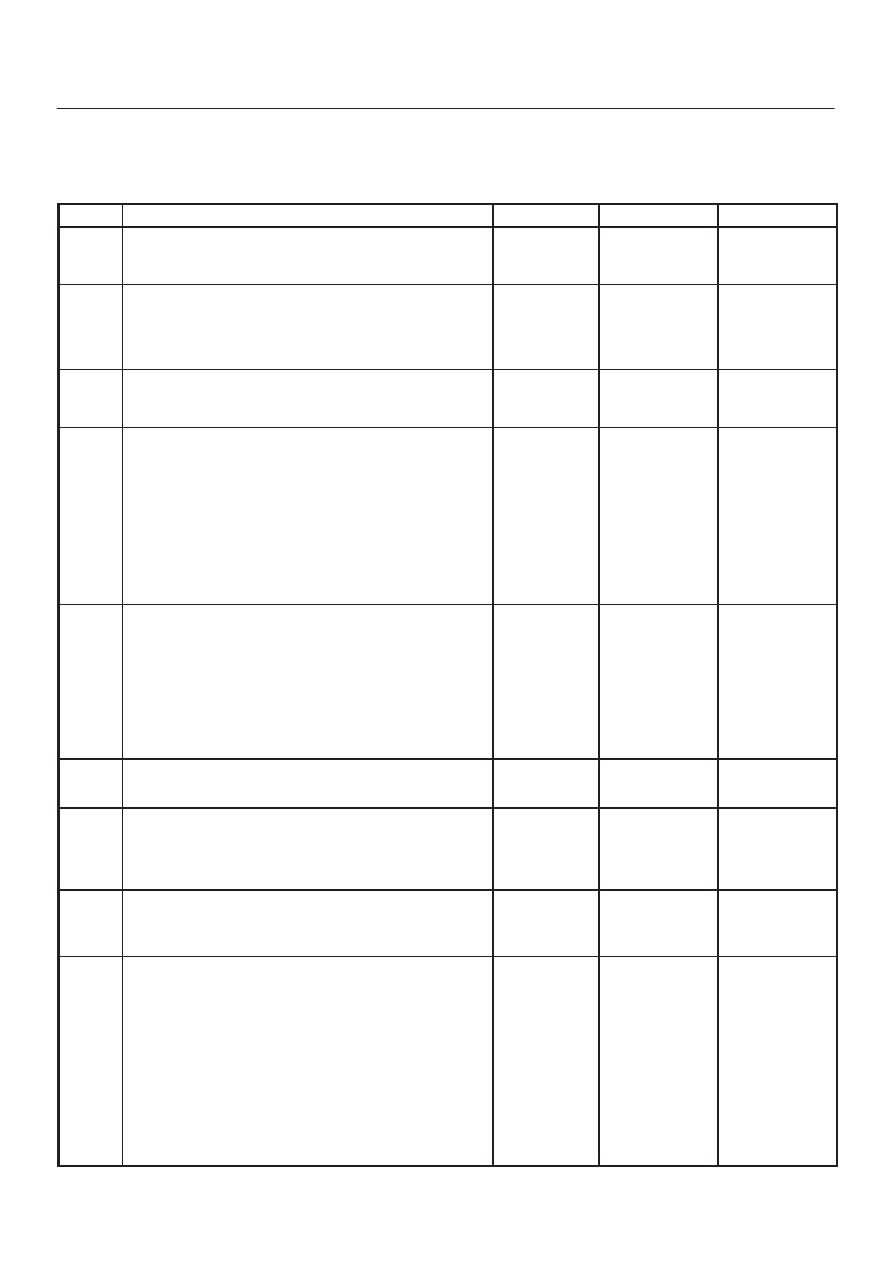

HARD START SYMPTOM

DEFINITION:

Engine cranks, but does not start for a long time. Does

eventually run, or may start but immediately stalls.

Step

Action

Value(s)

Yes

No

1

Was the ”On–Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD

System

Check

2

1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—

Verify repair

Go to Step 3

3

Was a visual/physical check performed?

—

Go to Step 4

Go to Visual /

Physical

Check

4

Check engine coolant temperature (ECT) sensor for

shift in value.

1. After 8 hours with the hood up and the engine not

running, connect the Tech 2.

2. Ignition ON, engine not running.

3. Using the Tech 2, compare Engine Coolant

Temperature to Intake Air Temperature.

Are ECT and IAT within the specified value of each

other?

±

5

°

C (

±

9

°

F)

Go to Step 8

Go to Step 5

5

1. Using a Tech 2, display the engine coolant

temperature and note the value.

2. Check the resistance of the engine coolant

temperature sensor.

3. For resistance specifications, refer to Temperature

vs. Resistance chart in DTC P0118.

Is the actual resistance near the resistance value in the

chart for the temperature that was noted?

—

Go to Step 7

Go to Step 6

6

Replace the ECT sensor.

Is the action complete?

—

Verify repair

—

7

Locate and repair high resistance or connection in the

ECT signal circuit or the ECT signal circuit or the ECM

sensor ground.

—

Verify repair

—

8

Check for a faulty, plugged, or incorrectly installed PCV

valve.

Was a problem found?

—

Verify repair

Go to Step 9

9

Visually/Physically inspect the secondary ignition

wires. Check for the following conditions:

D

Verify that all ignition wire resistance are less than

the specified value.

D

Verify that ignition wires are correctly routed to

eliminate cross–firing.

D

Verify that ignition wires are not arcing to ground.

Spraying the secondary ignition wires with a light

mist of water may help locate an intermittent

problem.

Was a problem found?

22.4 k

W

Verify repair

Go to Step 10