Content .. 1547 1548 1549 1550 ..

Opel Frontera UE. Manual - part 1549

6E–411

6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Cuts Out, Misses Symptom

(Cont'd)

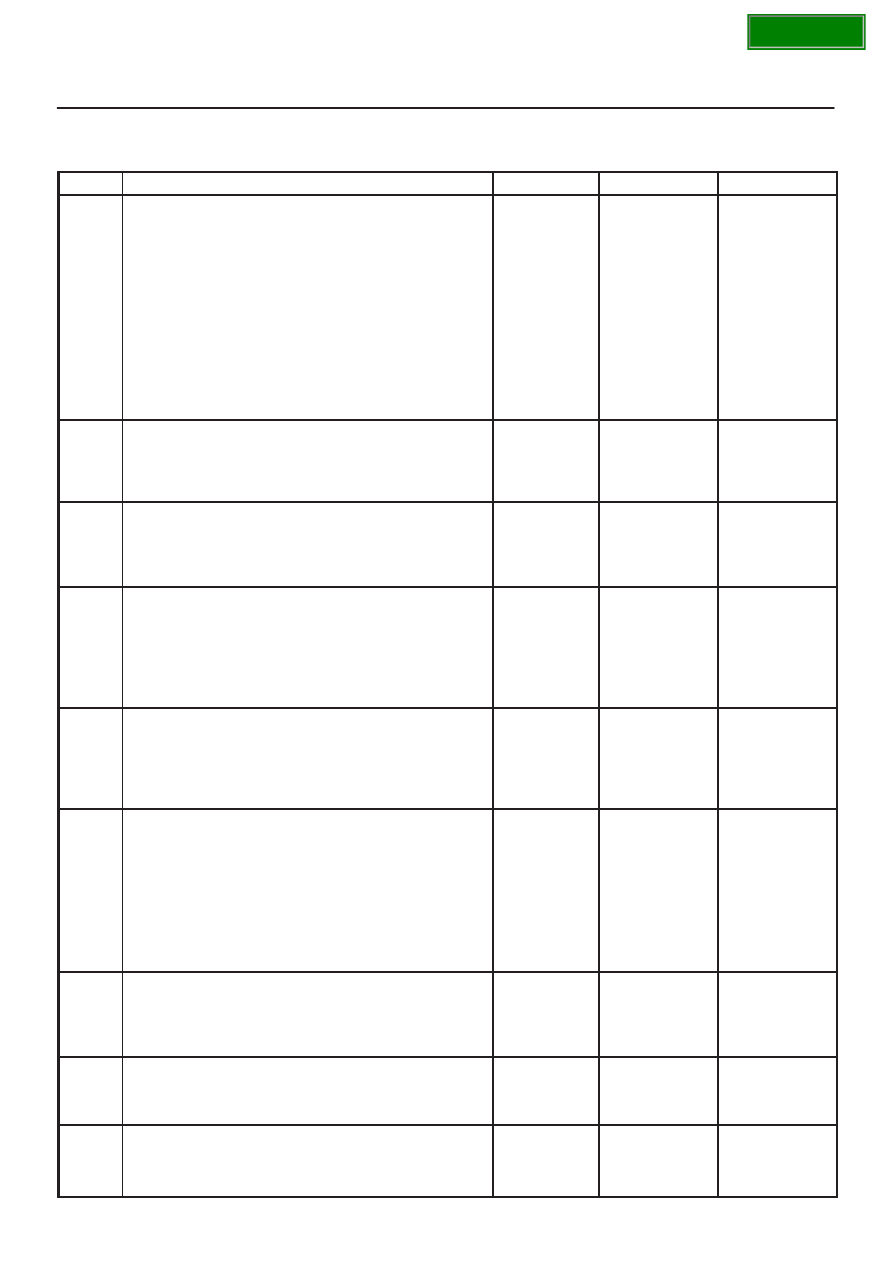

Step

No

Yes

Value(s)

Action

11

1. Visually/physically inspect for the following

conditions:

D

Restricted air intake system. Check for a

possible collapsed air intake duct, restricted

air filter element, or foreign objects blocking

the air intake system.

D

Large vacuum leak. Check for a condition that

causes a large vacuum leak, such as an

incorrectly installed or faulty PCV valve or

brake booster hose disconnected .

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 9

12

Check the injector connections. If any of the injectors

are connected to an incorrect cylinder, correct as

necessary.

Was a problem found?

—

Verify repair

Go to

Step 13

13

1. Perform the “Injector Coil/Balance Test” in

Fuel

Metering System.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 14

14

1. Check for fuel in the pressure regulator vacuum

hose.

2. If fuel is present, replace the fuel pressure regulator

assembly. Refer to

Fuel Metering System.

3. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 15

15

1. Check for proper ignition voltage output with spark

tester J 26792 (ST-125). Refer to

Electronic Ignition

System for the procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 16

16

1. Remove spark plugs. Check for wet plugs, cracks,

wear, improper gap, burned electrodes, or heavy

deposits. Refer to

Electronic Ignition System.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 17

17

1. Check for a loose ignition coil ground and ION

Sensing module circuit.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 18

18

1. Check ignition coils for cracks or carbon tracking.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 19

19

Using a Tech 2, monitor the TP 1, 2 angle with the

engine idling.

Is the TP angle at the specified value and steady?

8

∼

10%

Go to

Step 20

Refer to

DTC

P0123 for

further

diagnosis