Content .. 1496 1497 1498 1499 ..

Opel Frontera UE. Manual - part 1498

6E–207

6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

DTC P0300 – Engine Misfire Detected

(Cont'd)

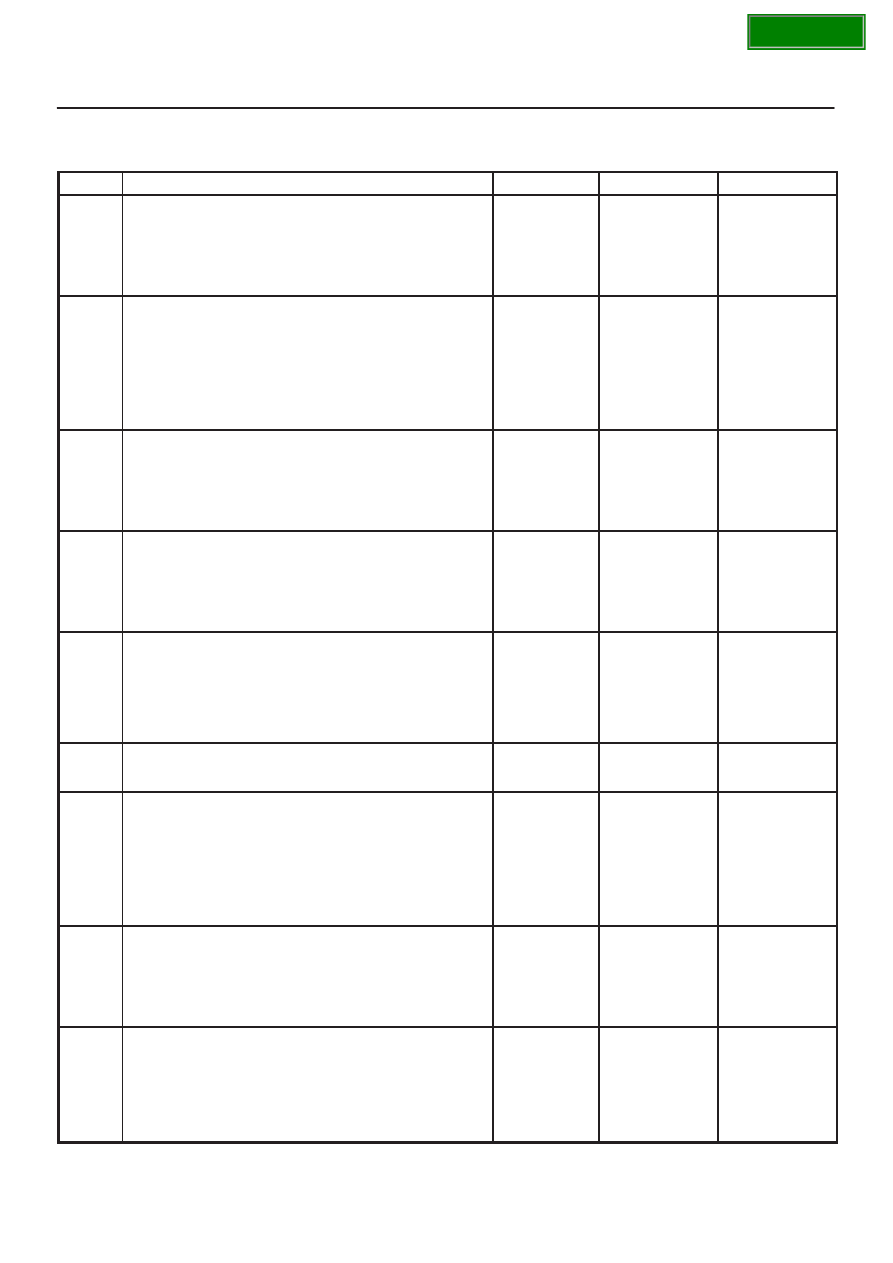

Step

No

Yes

Value(s)

Action

8

1. Install a spark tester at the spark plug end of the

ignition coil for a cylinder that indicated a misfire.

2. Crank the engine while observing the spark tester.

A crisp, blue spark should be observed.

Is adequate spark present?

—

Go to

Step 14

Go to

Step 9

9

1. Remove and visually/physically inspect the ignition

coil(s) associated with the cylinders that were

indicated as misfiring. Ensure that the coil(s) are

free of cracks.

2. If a problem is found, replace the damaged ignition

coil(s) as necessary.

Did any ignition coils require replacement?

—

Verify repair

Go to

Step 10

10

1. Remove the spark plugs from the cylinders that

were indicated as misfiring.

2. Visually inspect the spark plug electrodes.

Does your inspection reveal any spark plugs exhibiting

excessive fouling?

—

Go to

Engine

Mechanical

Diagnosis

Go to

Step 11

11

1. Visually inspect the spark plug insulators for cracks,

carbon tracking, or other damage.

2. If a problem is found, replace the faulty spark

plug(s) as necessary.

Did your inspection reveal a problem?

—

Verify repair

Go to

Step 12

12

1. Disconnect the MAF sensor electrical connector.

2. Operate the vehicle in “closed loop” while

monitoring the “BANK 1 L.T. FUEL TRIM” and

“BANK 1 S.T. FUEL TRIM” display on the Tech 2.

Do both values decrease below the specified values?

”BANK 1 L.T.

FUEL TRIM”

below +20%;

“BANK 1 S.T.

FUEL TRIM”

below +50%

Go to

Step 13

Replace the

ignition coil of

the affected

cylinder

13

Replace the ignition coil control module.

Is the action complete?

—

Verify repair

—

14

1. Visually and physically inspect the PCM injector

grounds, power grounds and sensor grounds to

ensure that they are clean, tight and in their proper

locations.

2. If a problem is found, correct the faulty ground

condition as necessary.

Did your inspection reveal a poor ground?

—

Verify repair

Go to

Step 15

15

1. Perform the “Fuel System Pressure Test”

procedure.

2. If a problem is found, repair as necessary (refer to

Engine Fuel or Fuel Metering System).

Was a fuel system problem found?

—

Verify repair

Go to

Step 16

16

1. Check the fuel for excessive water, alcohol, or other

contaminants (refer to

Diagnosis in Engine Fuel for

procedure).

2. If a problem is found, correct the contaminated fuel

condition as necessary.

Was the fuel contaminated?

—

Verify repair

Go to

Step 17