Opel Frontera UE. Manual - part 145

6A–4

ENGINE MECHANICAL (X22SE 2.2L)

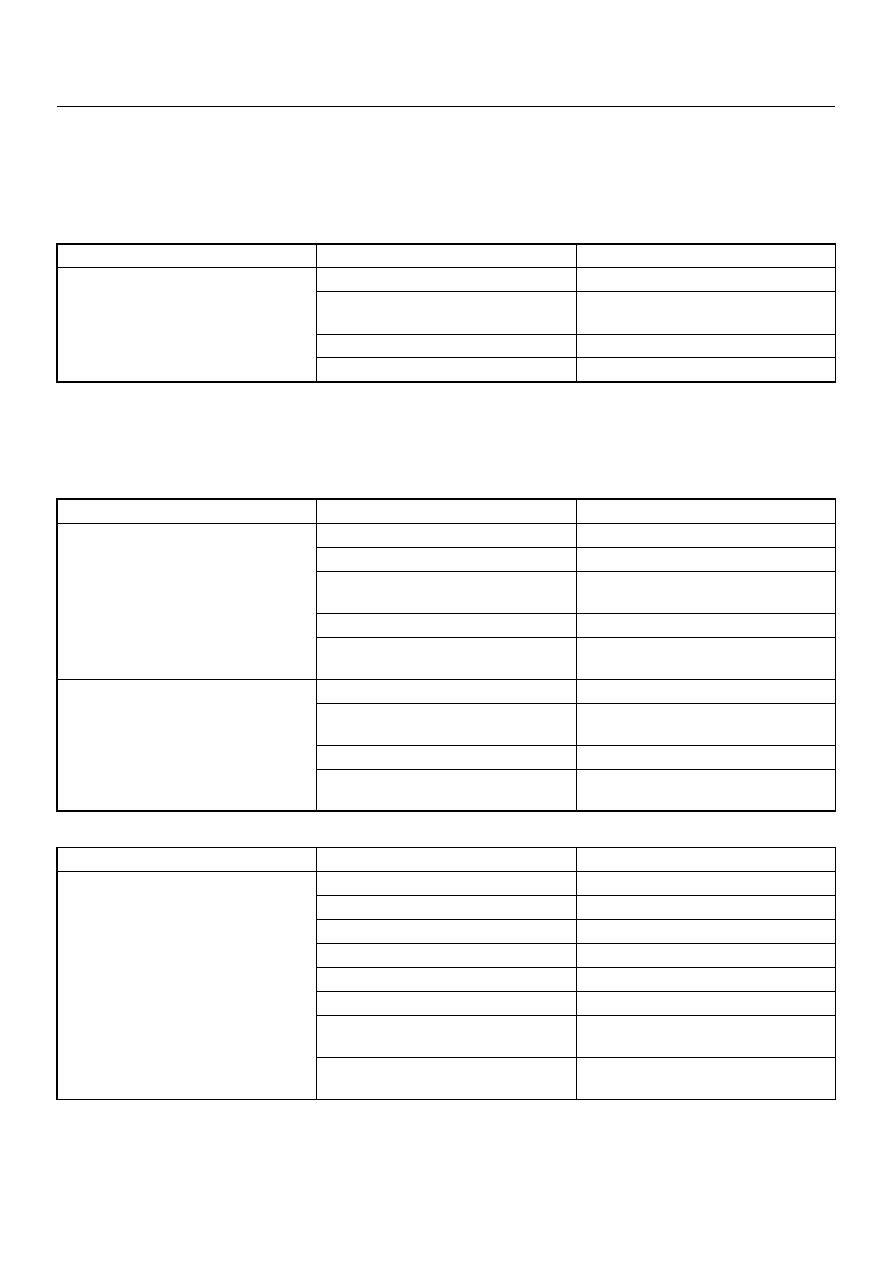

Engine Diagnosis

Hard Starting

1. Starting Motor Does Not Turn Over

Trouble Shooting Procedure

Turn on headlights and starter switch.

2. Ignition Trouble — Starting Motor Turns Over But

Engine Does Not Start

Spark Test

Disconnect a high tension cable from any spark plug.

Connect the spark plug tester J–26792 (ST–125), crank

the engine, and check if a spark is generated in the

spark plug tester. Before cranking the engine, make

sure that the spark plug tester is properly grounded. To

avoid electrical shock, do not touch the high tension

cable while the engine is running.

3. Trouble In Fuel System

Condition

Possible cause

Correction

Headlights go out or dim

considerably

Battery run down or under charged

Recharge or replace battery

Terminals poorly connected

Clean battery posts and terminals

and connect properly

Starting motor coil circuit shorted

Overhaul or replace

Starting motor defective

Overhaul or replace

Condition

Possible cause

Correction

Spark jumps across gap

Spark plug defective

Clean, adjust spark gap or replace

Ignition timing incorrect

Refer to Ignition System

Fuel not reaching fuel injector(s) or

engine

Refer to item 3 (Trouble in fuel

system)

Valve timing incorrect

Adjust

Engine lacks compression

Refer to item 4 (Engine lacks

compression)

No sparking takes place

Ignition coil disconnected or broken

Connect properly or replace

Electronic Ignition System with

module

Replace

Poor connections in engine harness

Correct

Powertrain Control Module cable

disconnected or defective

Correct or replace

Condition

Possible cause

Correction

Starting motor turns over and spark

occurs but engine does not start.

Fuel tank empty

Fill

Water in fuel system

Clean

Fuel filter clogged

Replace filter

Fuel pipe clogged

Clean or replace

Fuel pump defective

Replace

Fuel pump circuit open

Correct or replace

Evaporative Emission Control

System circuit clogged

Correct or replace

Multiport Fuel Injection System

faulty

Refer to “Electronic Fuel Injection"

section