Opel Frontera UE. Manual - part 15

1A–32

HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

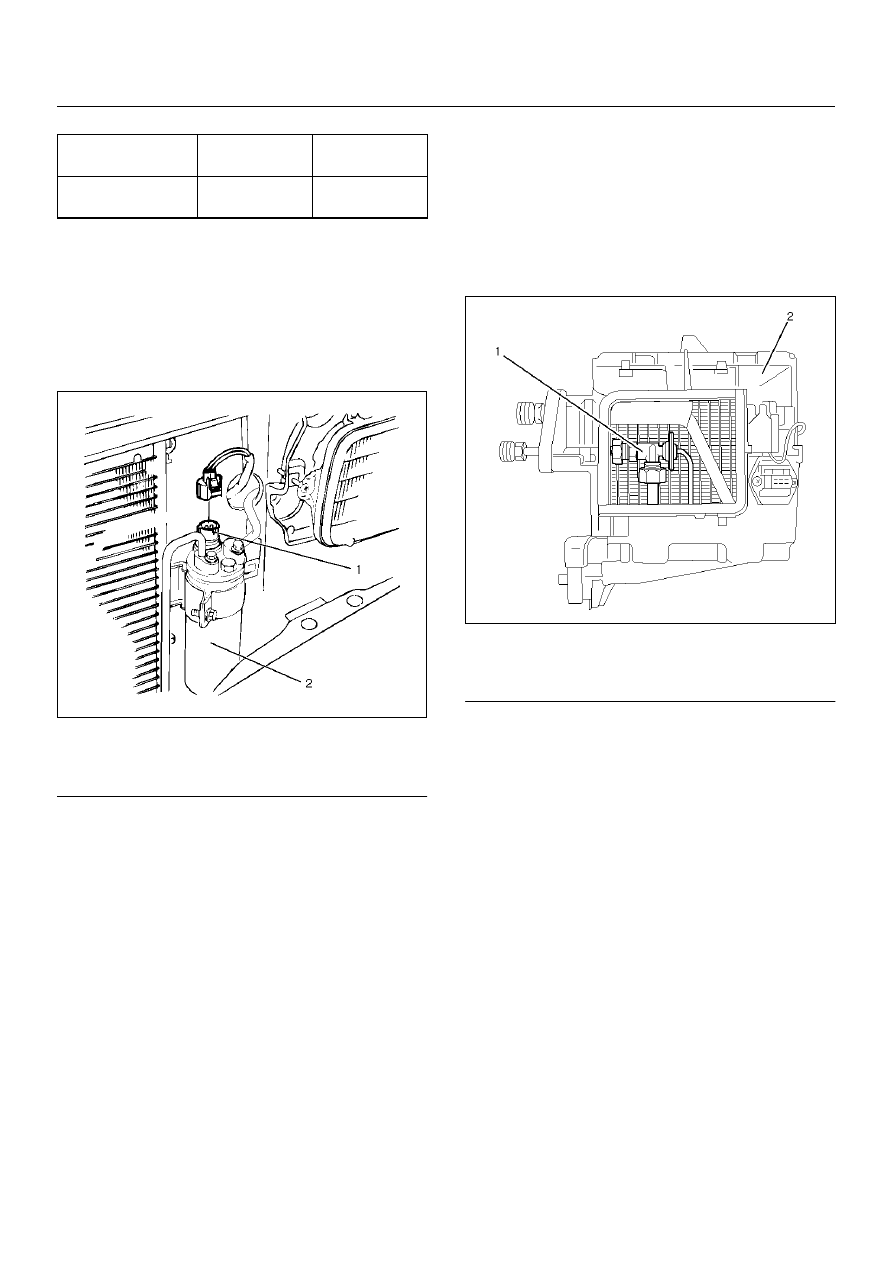

Pressure Sensor

The pressure sensor is installed on the upper part of the

receiver/drier. This sensor converts high pressure

detection of refrigerant to an electrical voltage signal

and supplies it to the PCM. The PCM controls switching

compressor idle speed and cooling fan operation by the

electrical voltage signal.

875RX002

EndOFCallout

Expansion Valve

This expansion valve is an external pressure type and it

is installed at the evaporator intake port.

The expansion valve converts the high pressure liquid

refrigerant sent from the receiver/drier to a low pressure

liquid refrigerant by forcing it through a tiny port before

sending it to the evaporator.

This type of expansion valve consists of a temperature

sensor, diaphragm, ball valve, ball seat, spring

adjustment screw, etc.

The temperature sensor contacts the evaporator outlet

pipe, and converts changes in temperature to pressure.

It then transmits these to the top chamber of the

diaphragm.

The refrigerant pressure is transmitted to the

diaphragm's bottom chamber through the external

equalizing pressure tube.

The ball valve is connected to the diaphragm. The

opening angle of the expansion valve is determined by

the force acting on the diaphragm and the spring

pressure.

The expansion valve regulates the flow rate of the

refrigerant. Accordingly, when a malfunction occurs to

this expansion valve, both discharge and suction

pressure get low, resulting in insufficient cooling

capacity of the evaporator.

The calibration has been changed to match the

characteristics of HFC-134a.

874RX009

EndOFCallout

Evaporator

The evaporator cools and dehumidifies the air before

the air enters the passenger compartment.

High-pressure liquid refrigerant flows through the

expansion valve into the low-pressure area of the

evaporator. The heat in the air passing through the

evaporator core is lost to the cooler surface of the core,

thereby cooling the air.

As heat is lost between the air and the evaporator core

surface, moisture in the vehicle condenses on the

outside surface of the evaporator core and is drained off

as water.

When the evaporator malfunctions, the trouble will show

up as an inadequate supply of cool air. The cause is

typically a partially plugged core due to dirt, or a

malfunctioning blower motor.

The evaporator core with a laminate louver fin is a

single-sided tank type where only one tank is provided

under the core.

Condenser fan

ON

(kPa/psi)

OFF

(kPa/psi)

Medium-pressure

control

1471.0

±

98.1

(213.3

±

14.2)

1078.7

±

117.7

(156.4

±

17.1)

Legend

(1) Pressure Switch

(2) Receiver Drier

Legend

(1) Expansion Valve

(2) Evaporator Assembly