Nissan Cube. Manual - part 940

TM-16

< PREPARATION >

[6MT: RS6F94R]

PREPARATION

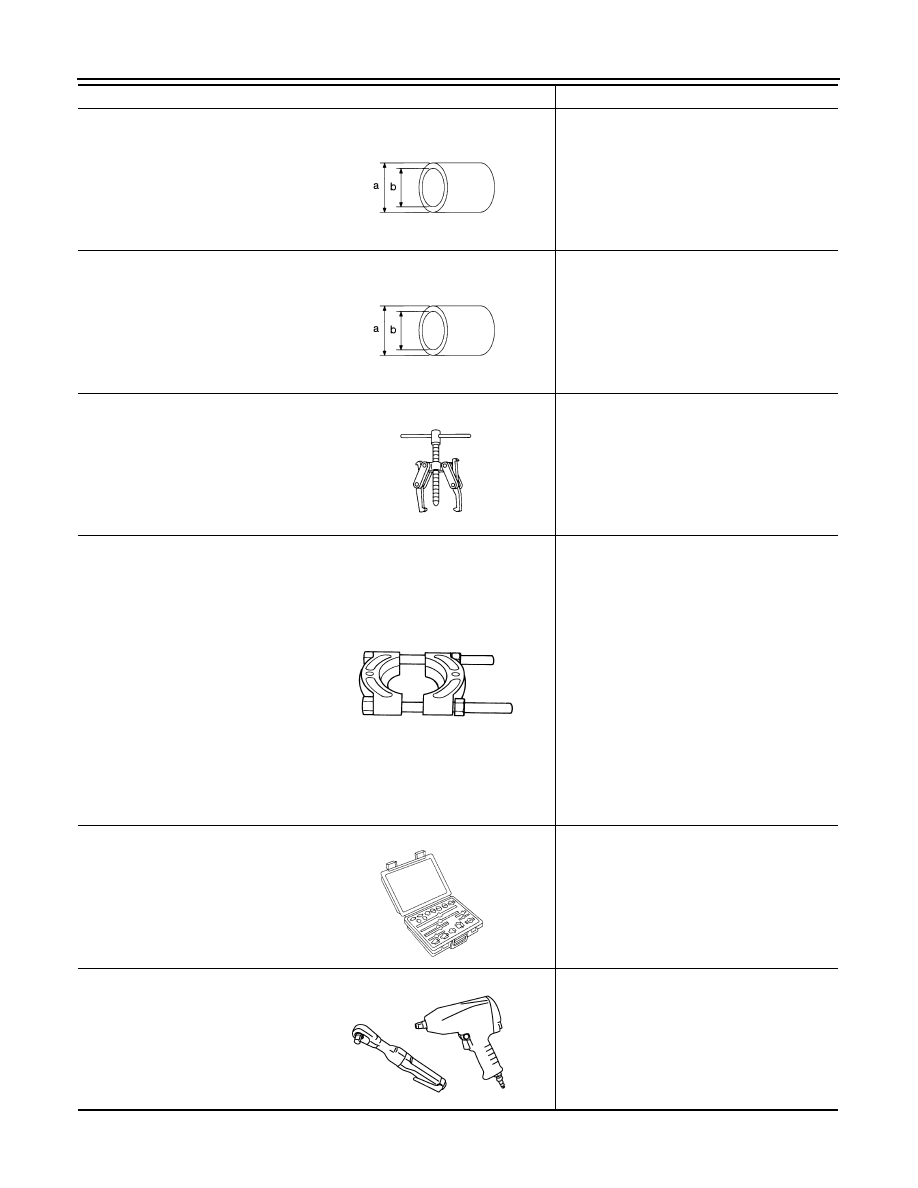

Drift

a: 45 mm (1.77 in) dia.

b: 39 mm (1.54 in) dia.

Installing differential side bearing inner race

(clutch housing side)

Drift

a: 52 mm (2.05 in) dia.

b: 45 mm (1.77 in) dia.

Installing differential side bearing inner race

(transaxle case side)

Puller

• Removing differential side bearing inner

race (clutch housing side)

• Removing differential side bearing inner

race (transaxle case side)

Puller

• Removing differential side bearing inner

race (clutch housing side)

• Removing differential side bearing inner

race (transaxle case side)

• Removing input shaft rear bearing

• Removing input shaft front bearing

• Removing mainshaft rear bearing inner race

• Removing 6th main gear

• Removing 4th main gear

• Removing 5th main gear

• Removing 1st main gear

• Removing 1st-2nd synchronizer hub as-

sembly

• Removing 2nd main gear

• Removing 3rd main gear

• Removing mainshaft front bearing inner

race

Remover

• Removing bushing

• Removing mainshaft rear bearing outer

race

Power tool

Loosening bolts and nuts

Tool name

Description

S-NT474

S-NT474

NT077

ZZB0823D

S-NT134

PBIC0190E