Nissan Cube. Manual - part 504

FSU-10

< REMOVAL AND INSTALLATION >

FRONT COIL SPRING AND STRUT

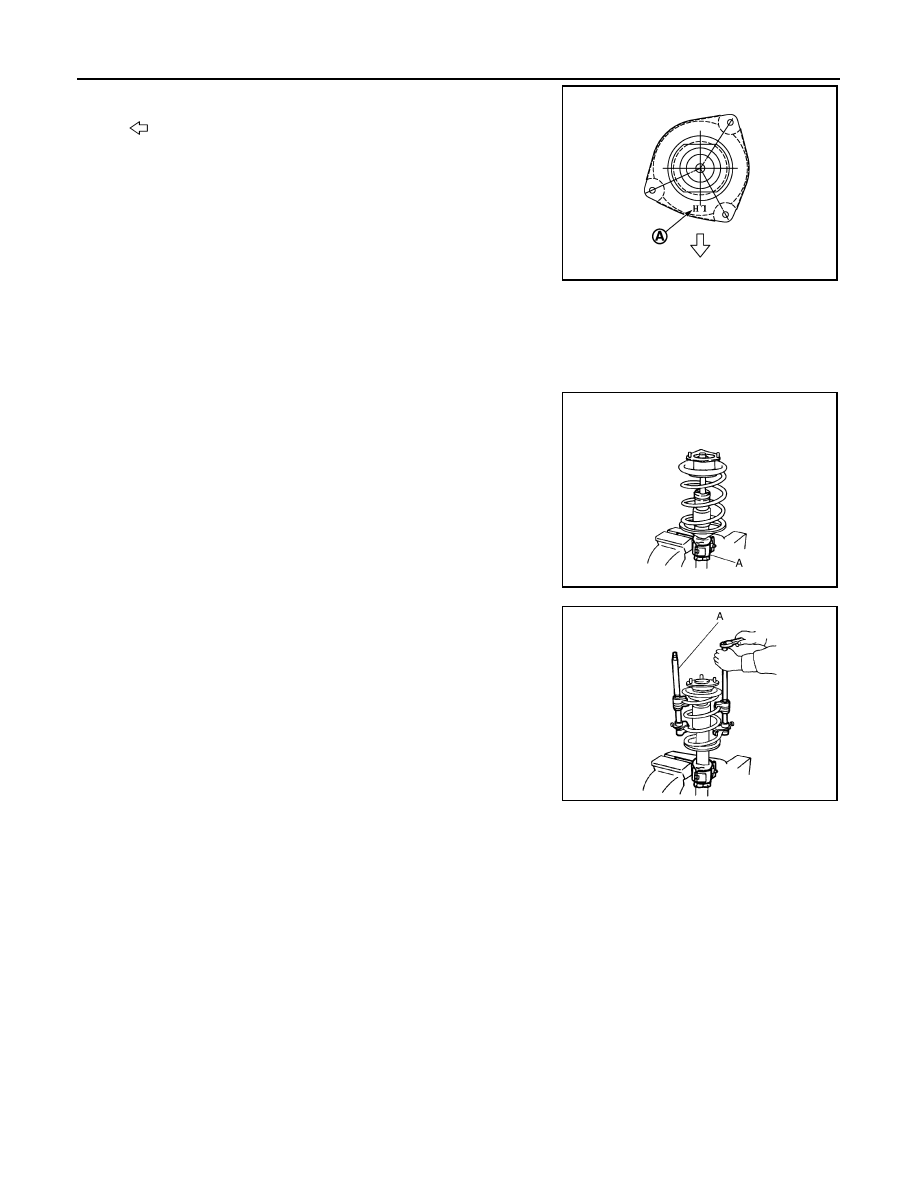

• Become it in ID letter (A) an illustration to the body front side.

• Perform final tightening of bolts and nuts, under unladen conditions

with tires on level ground.

Disassembly and Assembly

INFOID:0000000009948823

DISASSEMBLY

CAUTION:

Never damage strut assembly piston rod when removing components from strut assembly.

1.

Install strut attachment (A) [SST: ST35652000 (

—

)] to strut

assembly and secure it in a vise.

CAUTION:

When installing the strut attachment to strut assembly,

wrap a shop cloth around strut to protect from damage.

2.

Using a spring compressor (A) (commercial service tool), com-

press coil spring between strut mounting bearing and lower seat

(strut assembly) until coil spring with a spring compressor is

free.

CAUTION:

Be sure a spring compressor is securely attached to coil

spring. Compress coil spring.

3.

Check coil spring with a spring compressor between strut

mounting bearing and lower seat (strut assembly) is free. And

then remove piston rod lock nut while securing the piston rod tip

so that piston rod does not turn.

4.

Remove strut mounting insulator and strut mounting bearing,

and bound bumper from strut.

5.

After removing coil spring with a spring compressor (commercial service tool), then gradually release a

spring compressor.

CAUTION:

Loosen while making sure coil spring attachment position does not move.

6.

Remove the strut attachment [SST: ST35652000 (

—

)] from strut.

ASSEMBLY

1.

Install strut attachment [SST: ST35652000 (

—

)] to strut and secure it in a vise.

CAUTION:

When installing the strut attachment to strut assembly, wrap a shop cloth around strut to protect

from damage.

2.

Install bound bumper onto strut mounting insulator.

3.

Compress coil spring using a spring compressor (commercial service tool), and install it onto strut assem-

bly.

CAUTION:

: Vehicle front

JPEIA0023JP

JPEIA0006ZZ

JPEIA0168ZZ