Nissan Cube. Manual - part 410

EM-44

< REMOVAL AND INSTALLATION >

TIMING CHAIN

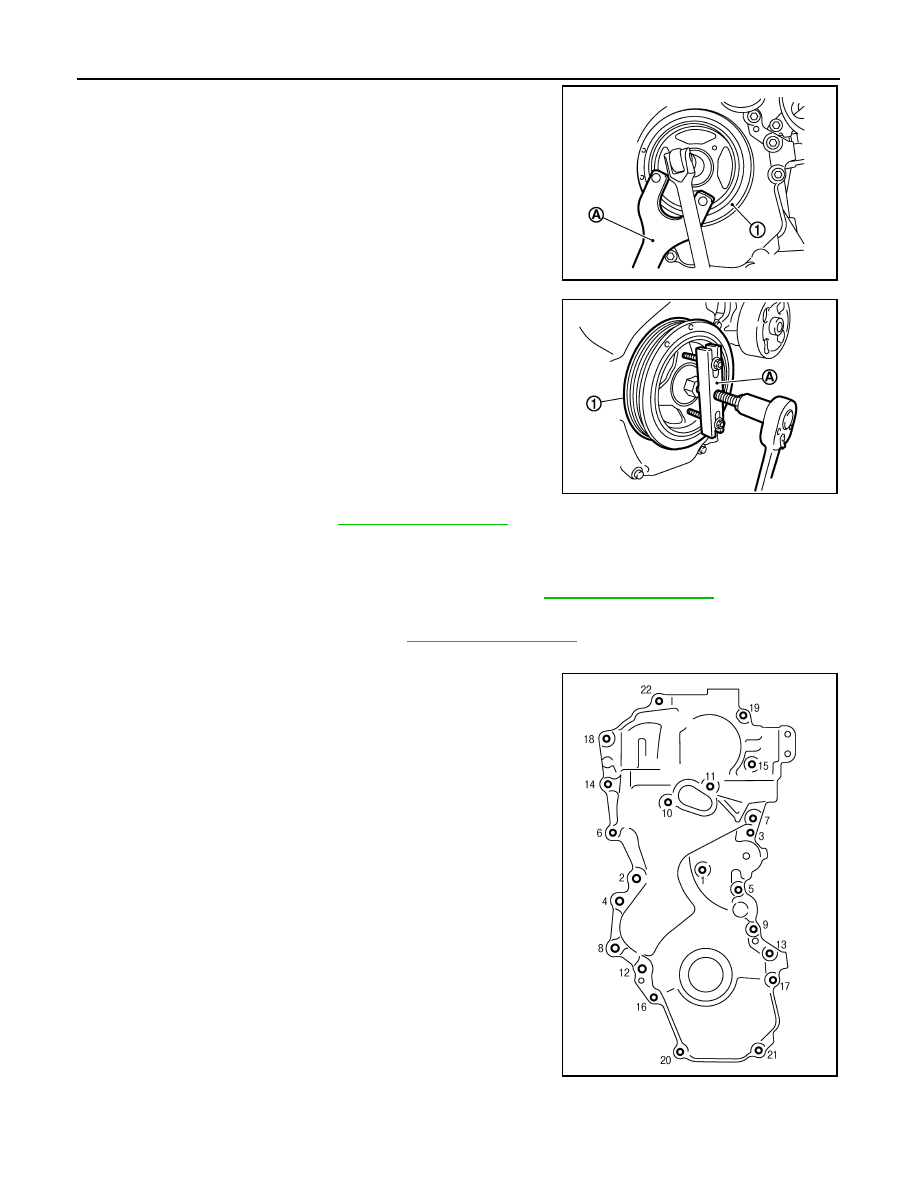

a.

Fix crankshaft pulley (1) with a pulley holder (commercial ser-

vice tool) (A), loosen crankshaft pulley bolt, and locate bolt seat-

ing surface at 10 mm (0.39 in) from its original position.

CAUTION:

Never remove the crankshaft pulley bolt as they will be

used as a supporting point for the pulley puller [SST:

KV11103000 (

—

)].

b.

Attach a pulley puller [SST: KV11103000 (

—

)] (A) in the M6

thread hole on crankshaft pulley (1), and remove crankshaft pul-

ley.

6.

Remove oil pan (lower). Refer to

NOTE:

If crankshaft sprocket and oil pump drive component are not removed, this step is unnecessary.

7.

Support the bottom surface of engine using a transmission jack, and then remove the engine mounting

bracket (RH) and the engine mounting insulator (RH). Refer to

8.

Remove intake valve timing control solenoid valve.

9.

Remove drive belt auto-tensioner. Refer to

10. Remove front cover with the following procedure:

a.

Loosen mounting bolts in the order of 22 to 1 as shown in the

figure.

PBIC3961E

PBIC3962E

PBIC3164J