Nissan Altima HL32 Hybrid. Manual - part 789

LU-8

< ON-VEHICLE MAINTENANCE >

[QR25DE]

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

Inspection

INFOID:0000000004211271

OIL LEVEL

• Before turning the Hybrid System ON, check the oil level. If the

Hybrid System is already ON, turn OFF the Hybrid System and

allow 10 minutes before checking.

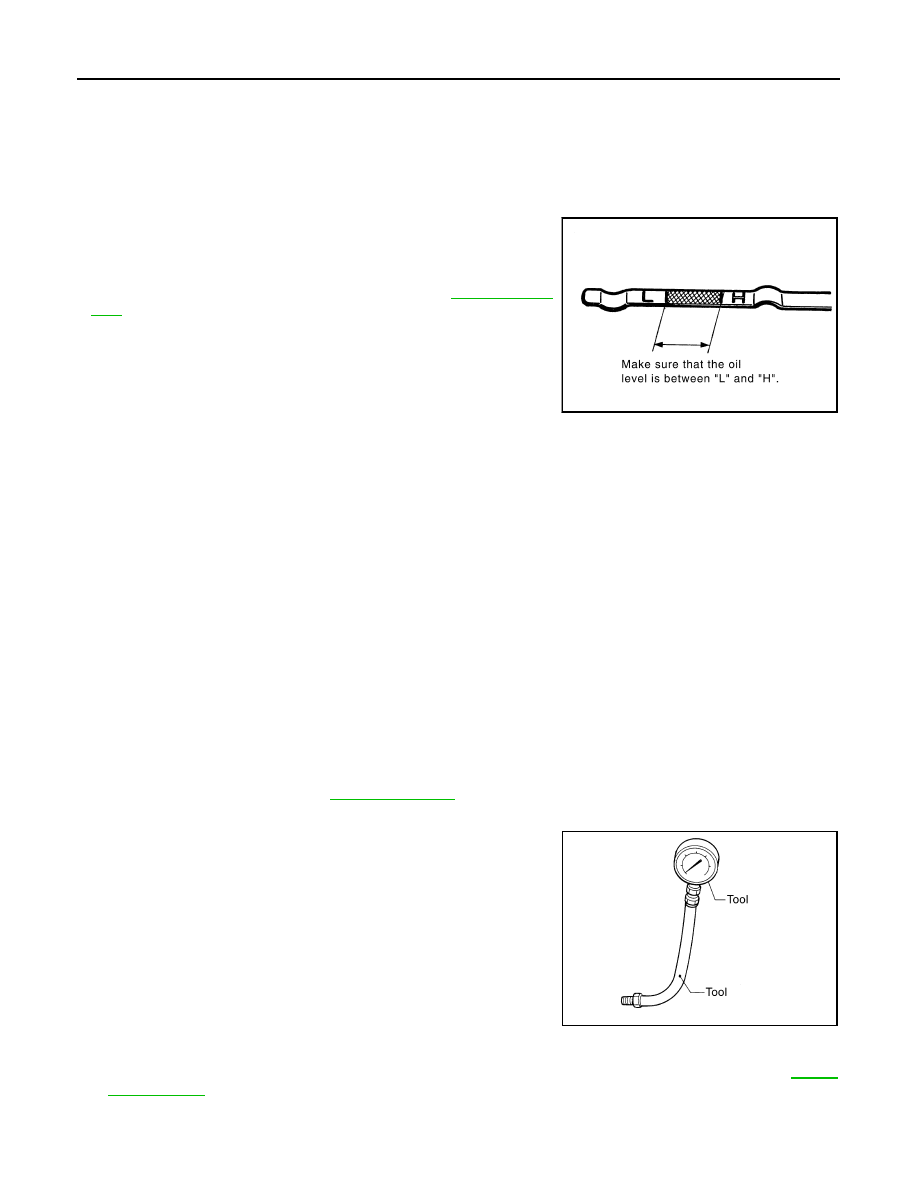

• Check that the oil level is within the range on the dipstick.

• If it is out of range, add oil as necessary. Refer to

ENGINE OIL APPEARANCE

• Check engine oil for white milky or excessive contamination.

• If engine oil becomes milky, it is highly probable that it is contaminated with engine coolant. Repair or

replace damaged parts.

OIL LEAKAGE

Check for oil leakage around the following areas:

• Oil pan

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• IVTC cover

• Front cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seal

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yourself, as engine oil may be hot.

• Put the selector lever in the Park “P” position.

1. Check engine oil level. Refer to

.

2. Remove undercover using power tool.

3. Disconnect oil pressure switch harness connector at oil pressure

switch. Remove oil pressure switch and install Tools.

CAUTION:

Do not drop or shock oil pressure switch.

4. Turn Hybrid System ON and warm the engine up to normal operating temperature.

5. Check oil pressure with Hybrid System ON and engine running under no-load, using Tool. Refer to

.

If difference is extreme, check oil passage and oil pump for oil leaks.

NOTE:

PBIC0249E

Tool numbers : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2)

WBIA0571E