Nissan Sentra. Manual - part 707

DIAGNOSIS AND REPAIR WORKFLOW

PWC-25

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

L

M

A

B

PWC

N

O

P

BASIC INSPECTION

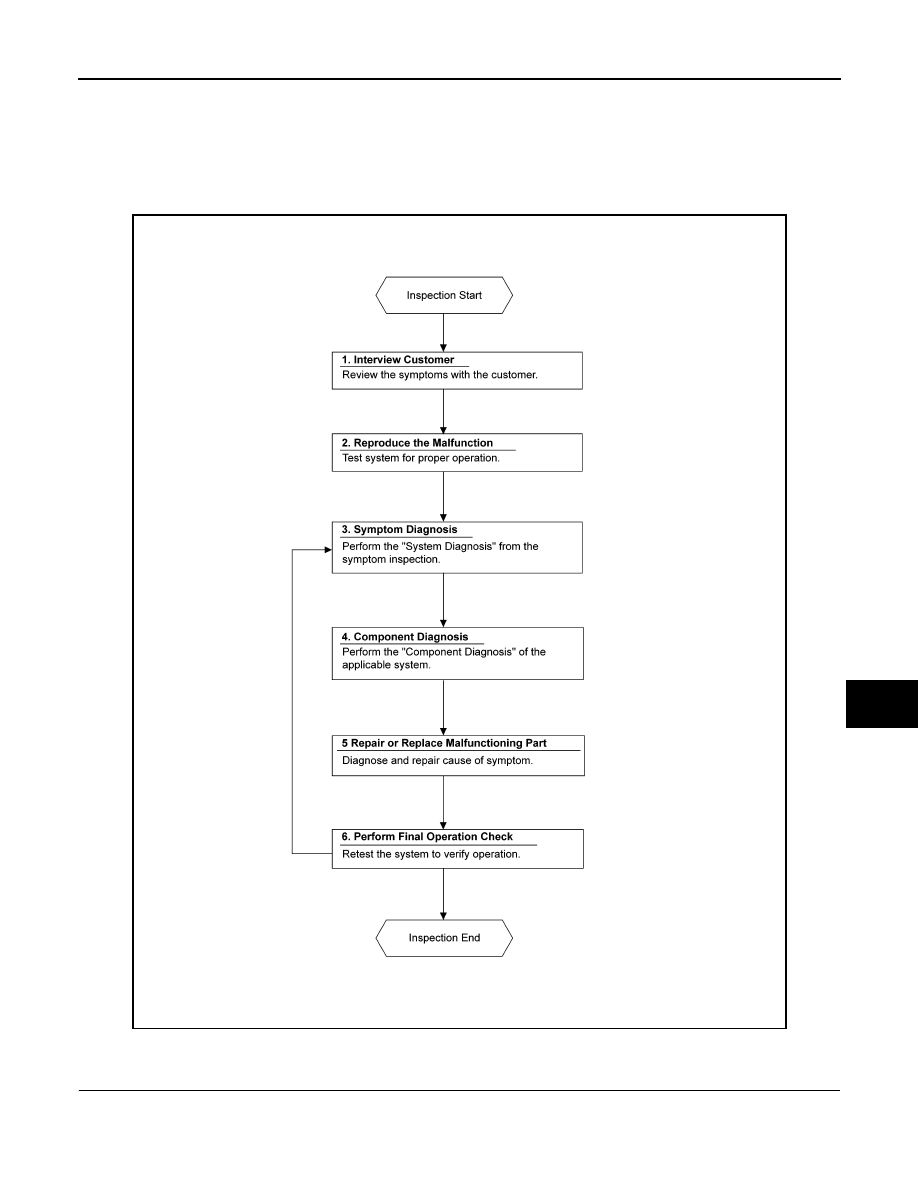

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000009757223

OVERALL SEQUENCE

DETAILED FLOW

1.

OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under

which the malfunction occurred.

ALKIA1982GB