Nissan Leaf. Manual - part 586

EVC-368

< DTC/CIRCUIT DIAGNOSIS >

COOLING FAN

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> GO TO 4.

4.

CHECK FUSE

1. Turn power switch OFF.

2. Pull out #73 fuse.

3. Check that the fuse is not fusing.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace the fuse after repairing the applicable circuit.

5.

CHECK COOLING FAN RELAY OUTPUT VOLTAGE-2

1. Turn power switch ON.

2. Check the voltage between fuse terminal and ground.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> GO TO 6.

6.

CHECK M/C RELAY OUTPUT CIRCUIT

1. Turn power switch OFF.

2. Remove M/C relay.

3. Check the continuity between M/C relay harness connector terminal and fuse harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> Check M/C relay routing circuit. Refer to

EVC-371, "Diagnosis Procedure"

.

NO

>> Repair or replace error-detected parts.

7.

CHECK COOLING FAN CONTROL MODULE POWER SUPPLY CIRCUIT

1. Turn power switch OFF.

2. Check the continuity between cooling fan relay harness connector and fuse terminal.

3. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-53, "Intermittent Incident"

.

NO

>> Repair or replace error-detected parts.

8.

CHECK COOLING FAN RELAY GROUND CIRCUIT

1. Turn power switch OFF.

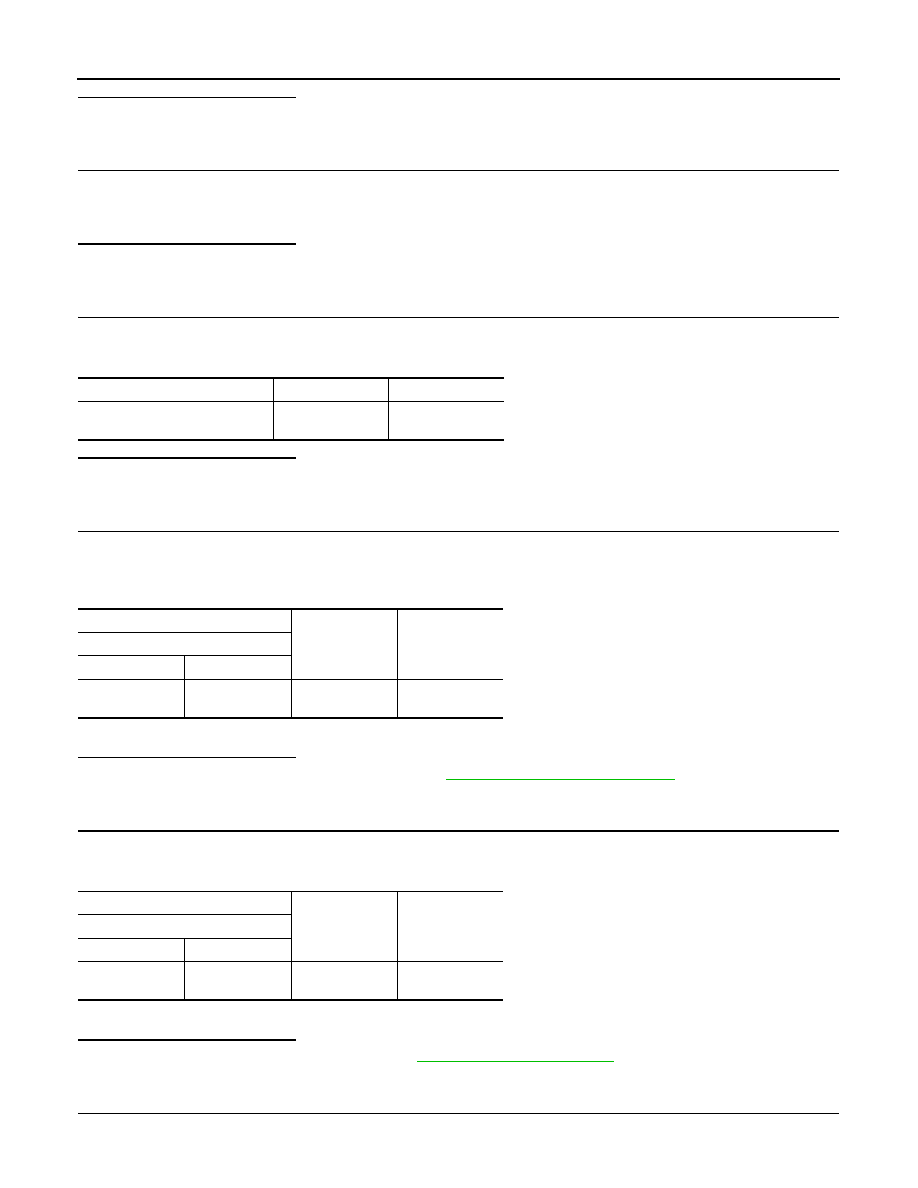

+

−

Voltage

#73 fuse terminal

Ground

12V battery volt-

age

+

−

Continuity

M/C relay

Connector

Terminal

E65

5

#73 fuse termi-

nal

Existed

+

−

Continuity

Cooling fan relay

Connector

Terminal

E18

1

#73 fuse termi-

nal

Existed