Nissan Leaf. Manual - part 468

P33EB TEMPERATURE SENSOR

EVB-155

< DTC/CIRCUIT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

EVB

N

O

P

Component Inspection

INFOID:0000000010121156

1.

CHECK BATTERY TEMPERATURE SENSOR

1. Remove battery temperature sensor. Refer to

EVB-222, "FRONT MODULE STACK : Exploded View"

(Front module stack) or

EVB-238, "REAR MODULE STACK : Exploded View"

(Rear module stack).

2. Check resistance between battery temperature sensor terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace battery temperature sensor.

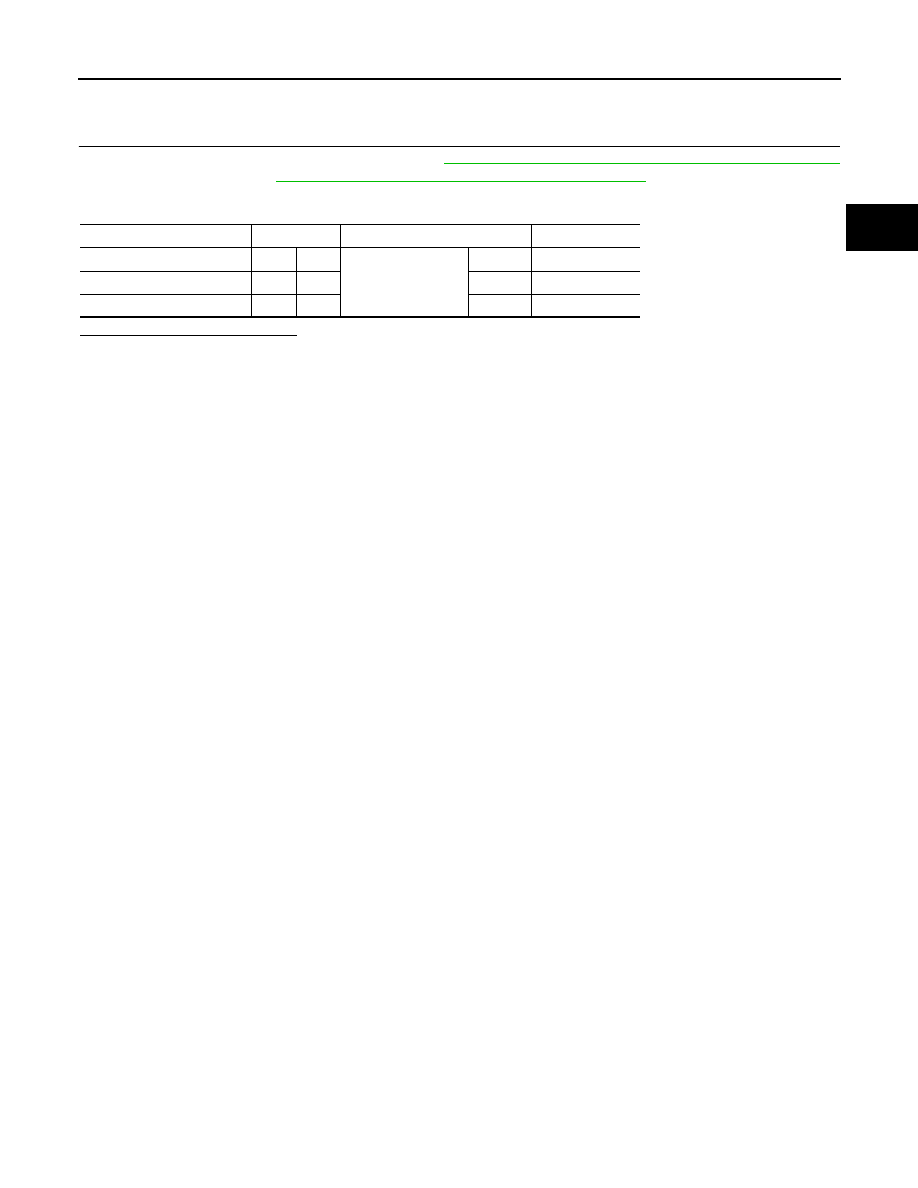

Battery temperature sensor

Terminals

Condition

Resistance (k

Ω)

1

1

5

Temperature

°C (°F)

10 (50)

Approx. 7.4

2

4

3

25 (77)

Approx. 4.0

4

2

1

40 (104)

Approx. 2.3