Nissan Leaf. Manual - part 320

BRC-70

< BASIC INSPECTION >

[WITH VDC]

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

Description

INFOID:0000000010120052

Always adjust the neutral position of steering angle sensor before driving when the following operation is per-

formed.

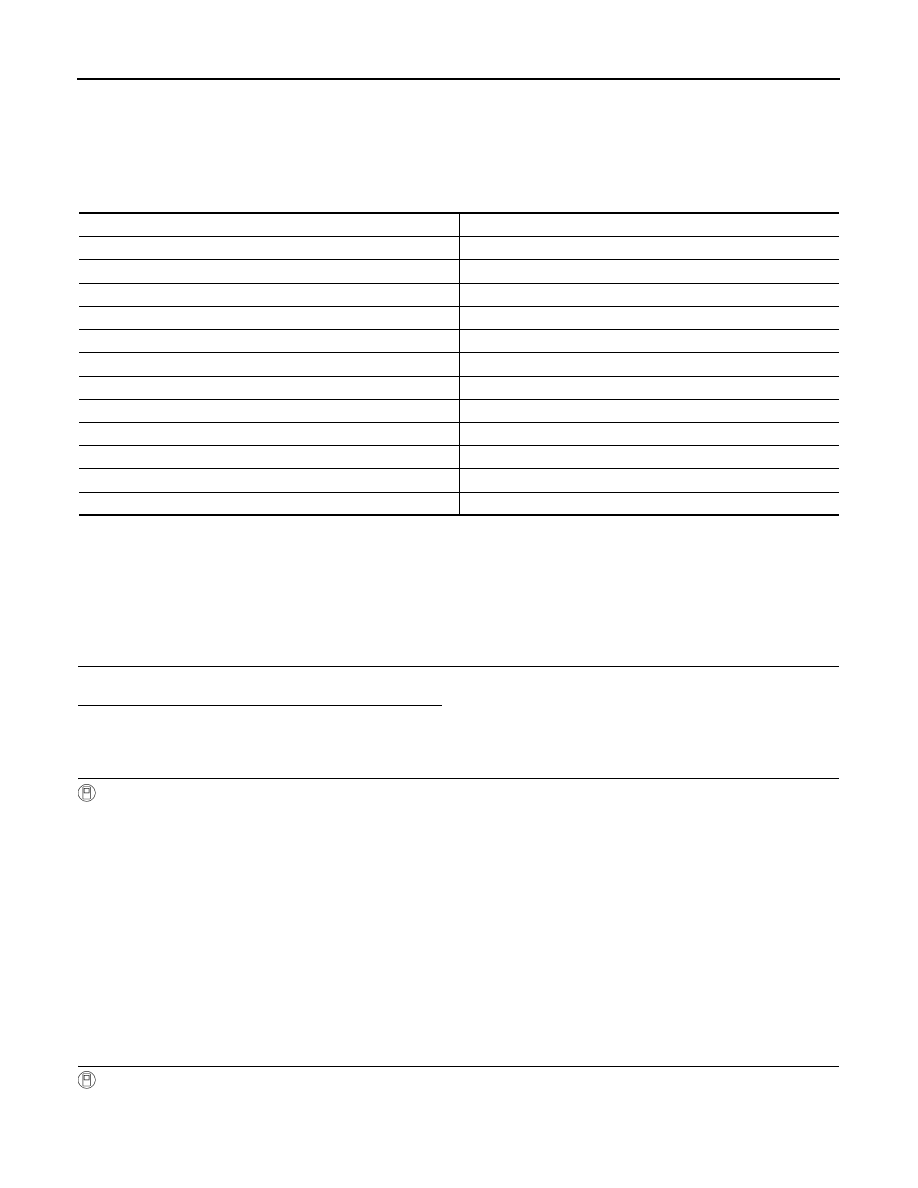

×: Required —: Not required

Work Procedure

INFOID:0000000010120053

ADJUST THE NEUTRAL POSITION OF STEERING ANGLE SENSOR

CAUTION:

Always use CONSULT when adjusting the neutral position of steering angle sensor. (It cannot be

adjusted other than with CONSULT.)

1.

CHECK THE VEHICLE STATUS (1)

Stop vehicle with front wheels in the straight-ahead position.

Does the vehicle stay in the straight-ahead position?

YES

>> GO TO 2.

NO

>> Steer the steering wheel to the straight-ahead position. Stop the vehicle.

2.

ADJUST NEUTRAL POSITION OF STEERING ANGLE SENSOR

With CONSULT

1. Turn the power switch ON.

CAUTION:

Never set the vehicle to READY.

2. Select “ABS”, “Work Support” and “ST ANGLE SENSOR ADJUSTMENT” in this order.

3. Select “START”.

CAUTION:

Never touch steering wheel while adjusting steering angle sensor.

4. After approx. 10 seconds, select “END”.

5. Turn power switch OFF, and then turn it ON again.

CAUTION:

Be sure to perform the operation above.

>> GO TO 3.

3.

CHECK DATA MONITOR (1)

With CONSULT

1. The vehicle is either pointing straight ahead, or the vehicle needs to be moved. Stop when it is pointing

straight ahead.

Procedure

Adjust the neutral position of steering angle sensor

Removing/ installing ABS actuator and electric unit (control unit)

—

Replacing ABS actuator and electric unit (control unit)

×

Removing/installing steering angle sensor

×

Replacing steering angle sensor

×

Removing/installing steering components

×

Replacing steering components

×

Removing/installing suspension components

×

Replacing suspension components

×

Removing/installing tire

—

Replacing tire

—

Tire rotation

—

Adjusting wheel alignment.

×