Nissan Frontier D22. Manual - part 164

VACUUM PIPING

BR-23

C

D

E

G

H

I

J

K

L

M

A

B

BR

VACUUM PIPING

PFP:47474

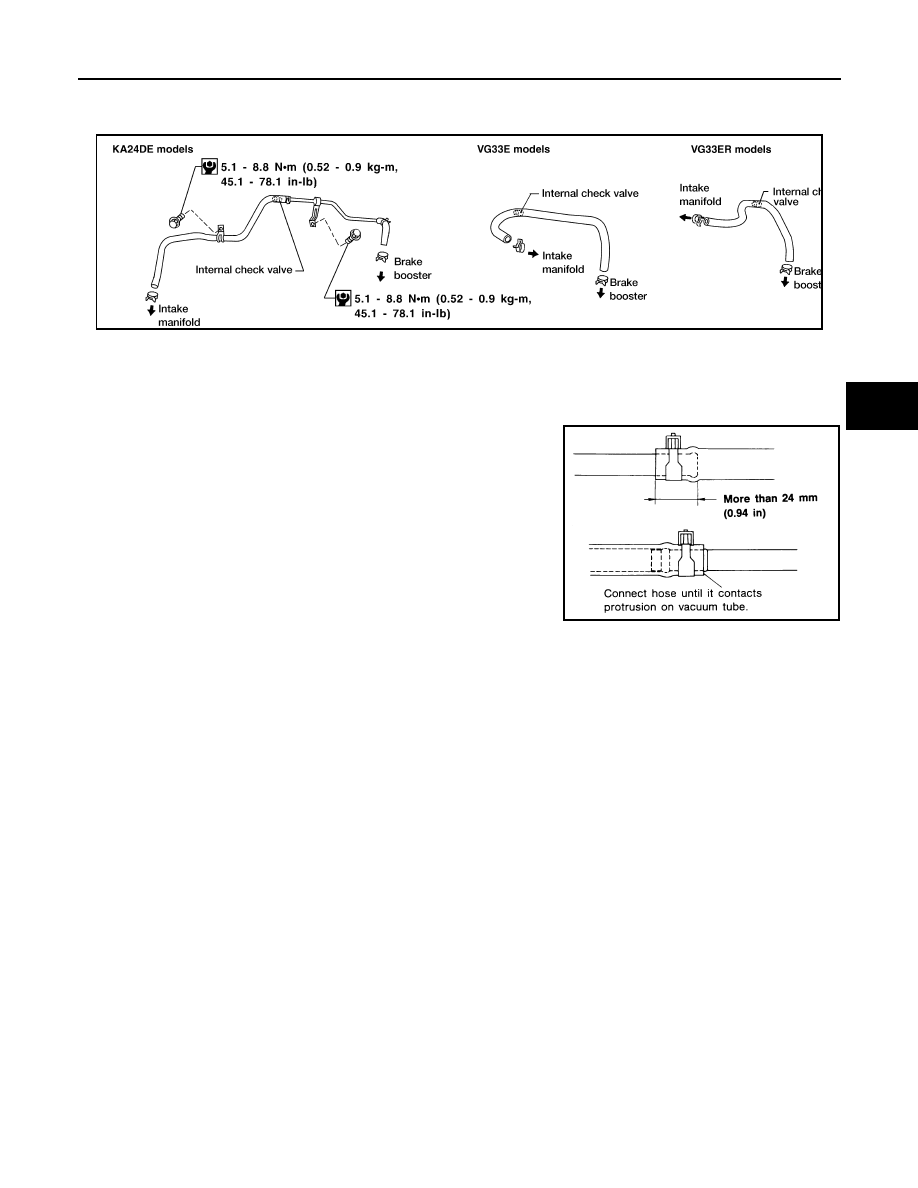

Vacuum Hose

EFS003FR

Removal and Installation

EFS003FS

CAUTION:

When installing vacuum hoses, pay attention to the following points.

●

Do not apply any oil or lubricants to vacuum hose with

check valve.

●

Insert vacuum tube into vacuum hose as shown.

●

Install vacuum hose with internal check valve, paying atten-

tion to its direction.

LBR159

SBR225B