Nissan Pathfinder. Manual - part 628

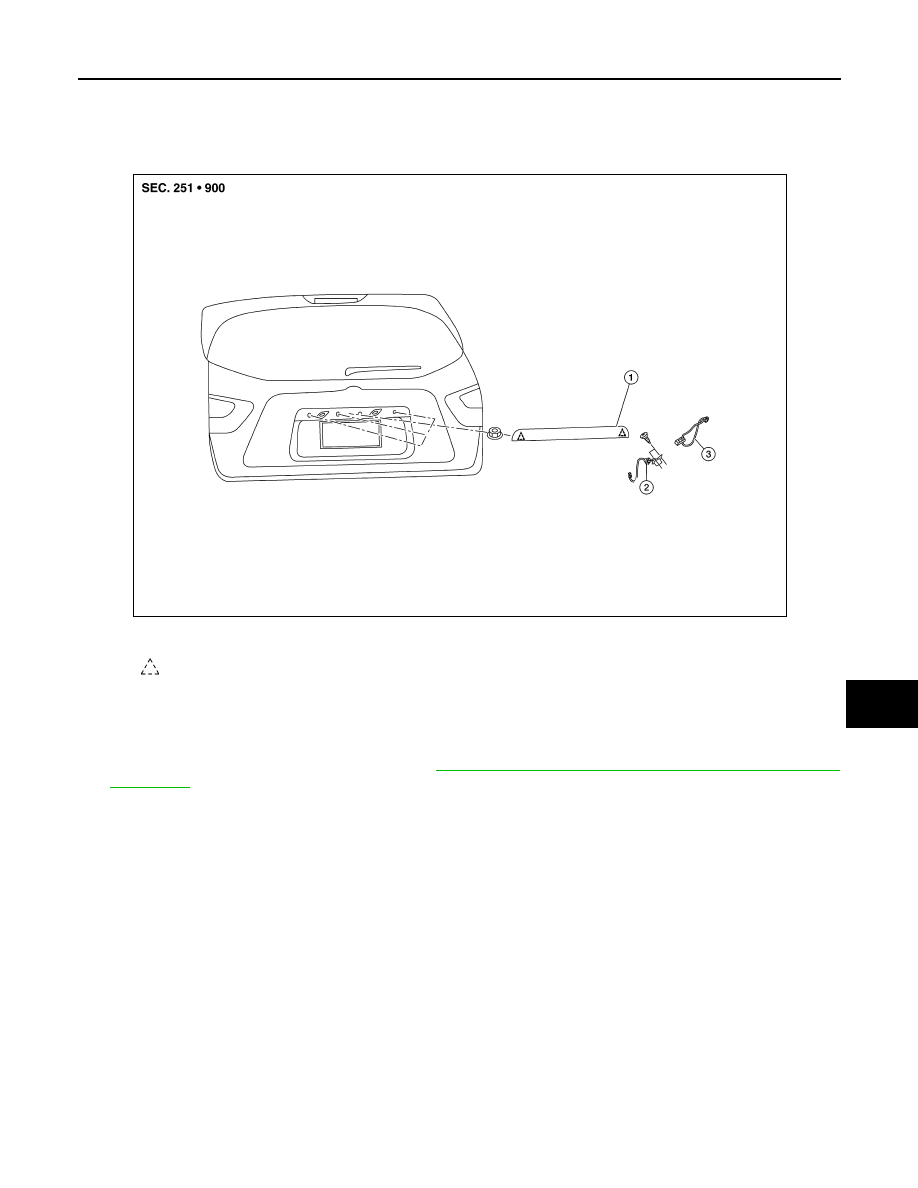

BACK DOOR OUTER FINISHER

EXT-43

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

L

M

A

B

EXT

N

O

P

BACK DOOR OUTER FINISHER

Exploded View

INFOID:0000000009176361

Removal and Installation

INFOID:0000000009176362

REMOVAL

1. Remove the back door lower finisher. Refer to

INT-35, "BACK DOOR LOWER FINISHER : Removal and

.

2. Disconnect the harness connectors from rear view camera and back door opener switch.

3. Remove the back door outer finisher nuts.

4. Release the clips, then remove the back door outer finisher.

5. Remove the following parts (if necessary) after removing back door outer finisher.

• Rear view camera

• Back door opener switch

• License plate lamp

INSTALLATION

Installation is in the reverse order of removal.

1.

Back door outer finisher

2.

Rear camera

3.

Back door opener request switch

Clip

AWKIA2640ZZ