Nissan Teana J32. Manual - part 932

PWO-8

< ON-VEHICLE REPAIR >

POWER SOCKET

POWER SOCKET

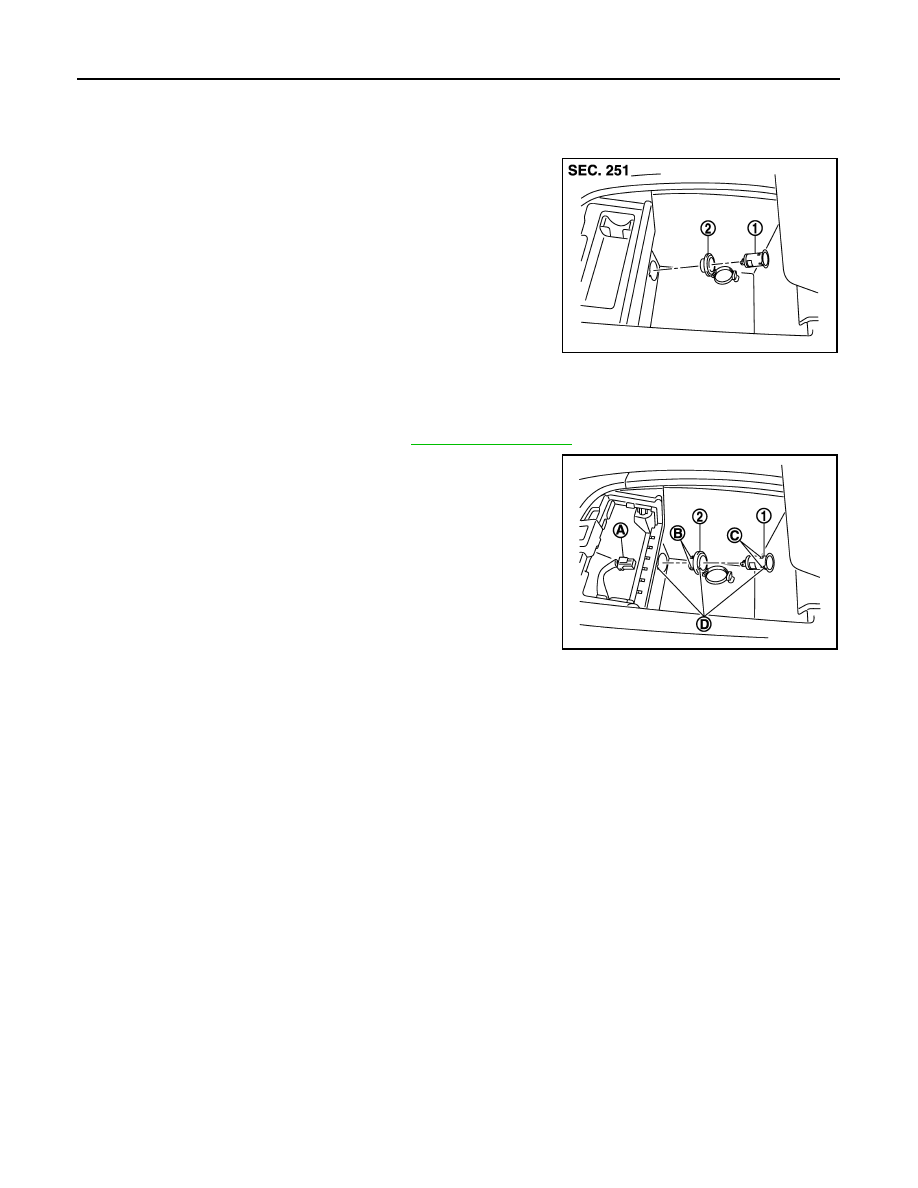

Exploded View

INFOID:0000000003792636

Removal and Installation

INFOID:0000000003792637

REMOVAL

1.

Remove center console assembly. Refer to

.

2.

Disconnect power socket connector (A).

3.

Pull out inner socket (1) by pushing the ring pawl (B) from the

inner socket hole (square) (C).

4.

Remove ring (2) from center console assembly while pressing

pawls.

INSTALLATION

Install in the reverse order of removal.

NOTE:

Align inner socket, ring and center console assembly cut out.

1

: Inner socket

2

: Ring

JPMIA1026ZZ

D

: Cut out

JPMIA1027ZZ