Nissan Teana J32. Manual - part 808

CHASSIS MAINTENANCE

MA-41

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

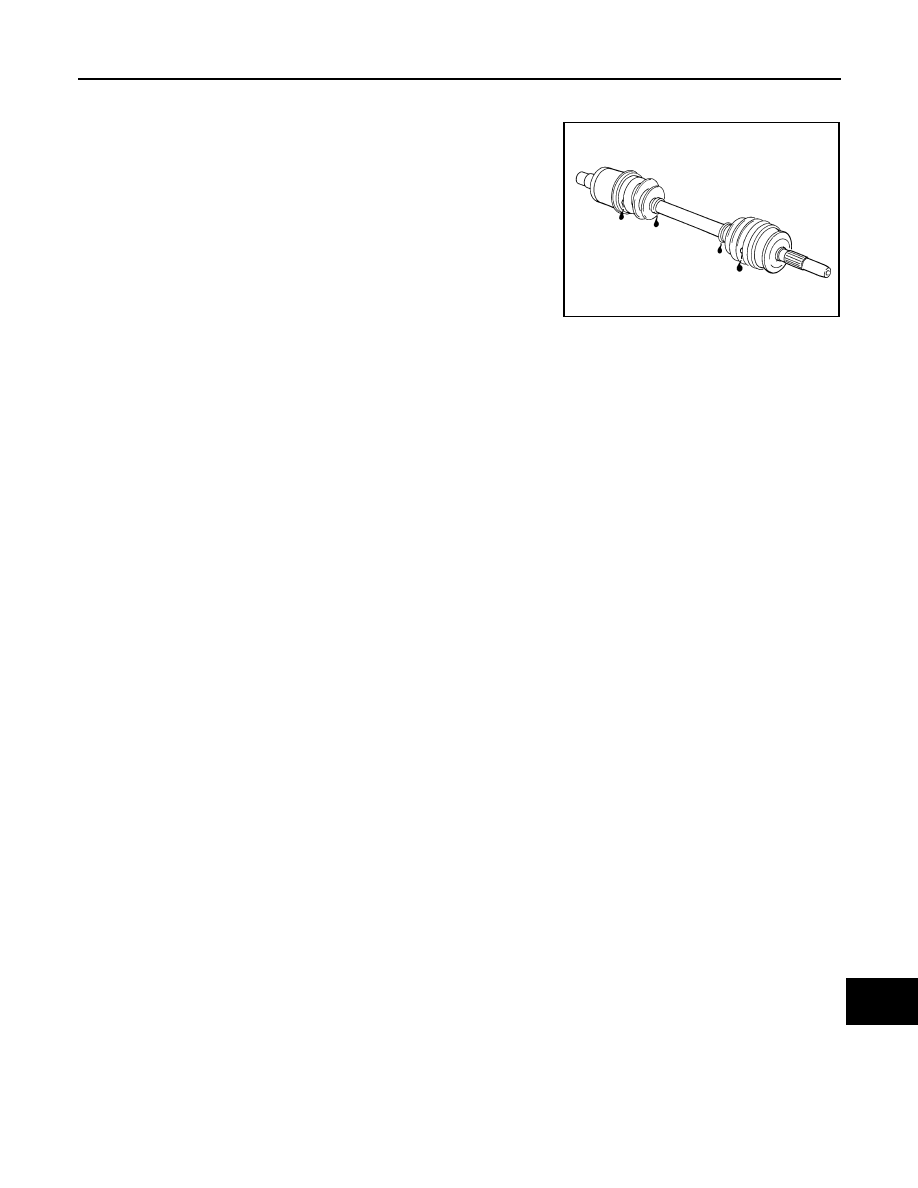

DRIVE SHAFT : Inspection

INFOID:0000000003858317

• Check boot and drive shaft for cracks, wear, damage and grease

leakage.

SFA108A