Nissan Teana J32. Manual - part 498

EM-116

< DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

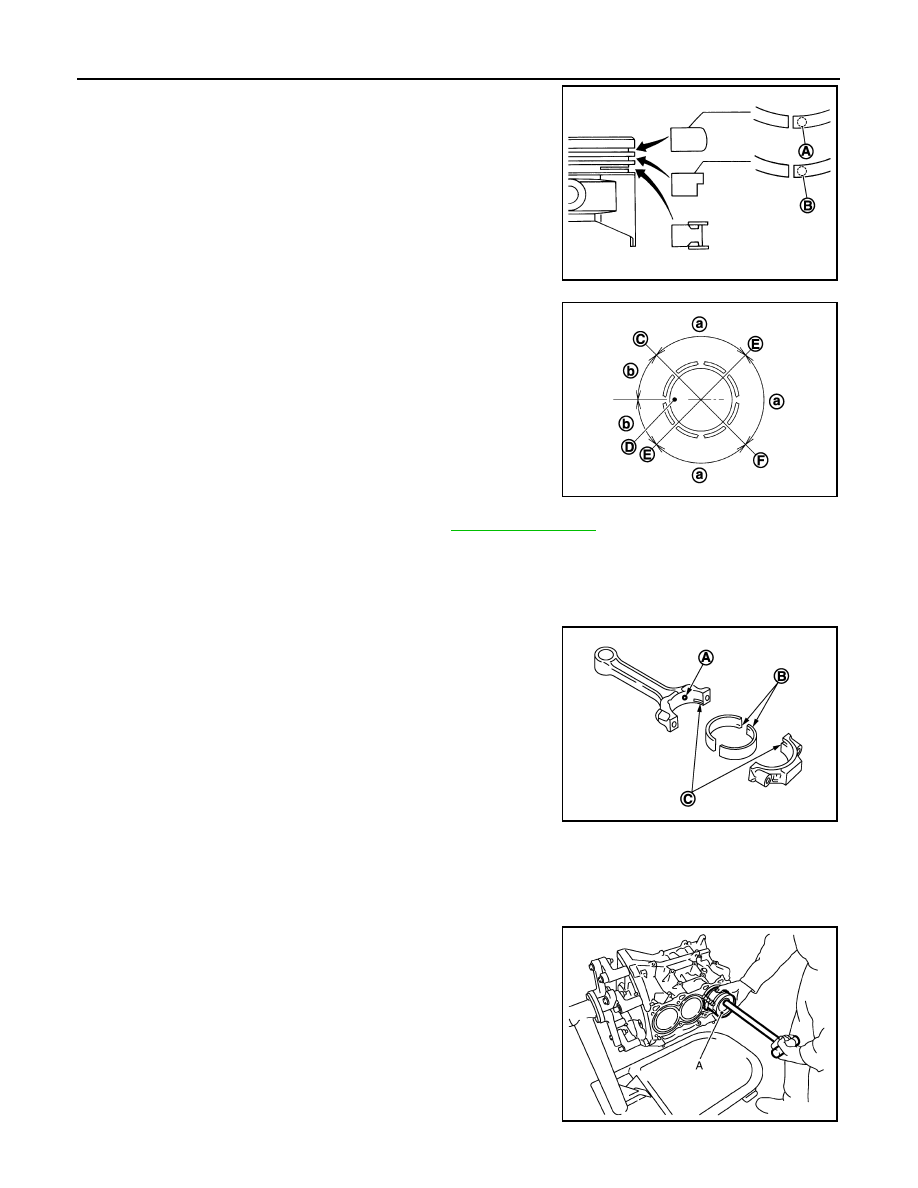

• If there is stamped mark on ring, mount it with marked side up.

NOTE:

If there is no stamp on ring, no specific orientation is required

for installation.

• Position each ring with the gap as shown in the figure referring

to the piston front mark (D).

• Check the piston rings side clearance. Refer to

11. Install connecting rod bearings to connecting rod and connecting rod bearing cap.

CAUTION:

Be careful not to drop connecting rod bearing, and to scratch the surface.

• Before installing connecting rod bearings, apply engine oil to the bearing surface (inside). Do not apply

engine oil to the back surface, but thoroughly clean it.

• When installing, align connecting rod bearing stopper protru-

sion (B) with cutout (C) of connecting rod and connecting rod

bearing cap to install.

• Ensure the oil hole (A) on connecting rod and that on the cor-

responding bearing are aligned.

12. Install piston and connecting rod assembly to crankshaft.

• Position crankshaft pin corresponding to connecting rod to be installed onto the bottom dead center.

• Apply engine oil sufficiently to the cylinder bore, piston and crankshaft pin journal.

• Match the cylinder position with the cylinder number on connecting rod to install.

• Be sure that front mark on piston crown is facing front of engine.

• Using a piston ring compressor [SST: EM03470000 (J8037)]

(A) or suitable tool, install piston with the front mark on the pis-

ton crown facing the front of the engine.

CAUTION:

Be careful not to damage the cylinder wall and crankshaft

pin, resulting from an interference of the connecting rod big

end.

Stamped mark:

VQ25DE

VQ35DE

Top ring (A)

: R

: —

Second ring (B)

: R 2

: 2 R

JPBIA0263ZZ

C

: Top ring gap

E

: Oil ring upper or lower rail gap (either of then)

F

: Second ring and oil ring spacer gap

a

: 90 degrees

b

: 45 degrees

JPBIA0205ZZ

JPBIA0206ZZ

JPBIA0207ZZ