содержание .. 715 716 717 718 ..

Nissan Tiida C11. Manual - part 717

EM-220

< DISASSEMBLY AND ASSEMBLY >

[MR18DE]

ENGINE UNIT

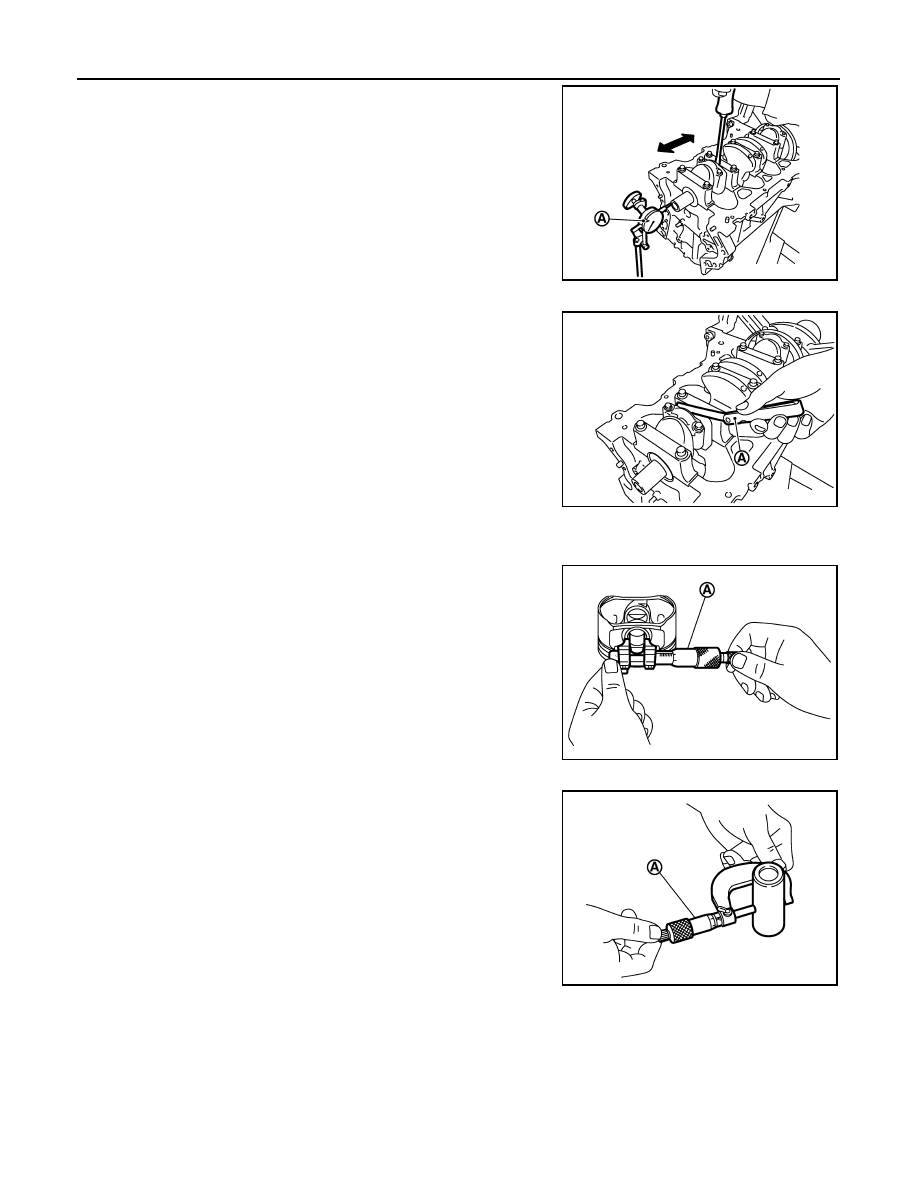

• Measure the clearance between thrust bearings and crankshaft

arm when crankshaft is moved fully forward or backward with a dial

indicator (A).

• If the measured value exceeds the limit, replace thrust bearings,

and measure again. If it still exceeds the limit, replace crankshaft

also.

CONNECTING ROD SIDE CLEARANCE

• Measure the side clearance between connecting rod and crank-

shaft arm with a feeler gauge (A).

• If the measured value exceeds the limit, replace connecting rod,

and measure again. If it still exceeds the limit, replace crankshaft

also.

PISTON TO PISTON PIN OIL CLEARANCE

Piston Pin Hole Diameter

Measure the inner diameter of piston pin hole with an inside

micrometer (A).

Piston Pin Outer Diameter

Measure the outer diameter of piston pin with a micrometer (A).

Piston to Piston Pin Oil Clearance

(Piston to piston pin oil clearance) = (Piston pin hole diameter) – (Piston pin outer diameter)

• If oil clearance is out of the standard, replace piston and piston pin assembly.

• When replacing piston and piston pin assembly, rfollow the "Piston to Cylinder Bore Clearance" procedure.

NOTE:

• Piston is available together with piston pin as assembly.

Standard

: 0.10 - 0.26 mm (0.0039 - 0.0102 in)

Limit

: 0.30 mm (0.012 in)

PBIC3252J

Standard

: 0.20 - 0.35 mm (0.0079 - 0.0138 in)

Limit

: 0.40 mm (0.0157 in)

PBIC3251J

Standard: 19.993 - 19.999 mm (0.7871 - 0.7874 in)

PBIC3265J

Standard: 19.989 - 19.995 mm (0.7870 - 0.7872 in)

PBIC3266J

Standard: 0.002 - 0.006 mm (0.0001 - 0.0002 in)