содержание .. 385 386 387 388 ..

Nissan Tiida C11. Manual - part 387

EC-198

< COMPONENT DIAGNOSIS >

[HR16DE (WITH EURO-OBD)]

P0335 CKP SENSOR (POS)

2.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000001670962

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E15. Refer to Ground Inspection in

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY CIRCUIT-I

1.

Disconnect crankshaft position (CKP) sensor (POS) harness connector.

2.

Turn ignition switch ON.

3.

Check the voltage between CKP sensor (POS) harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> GO TO 3.

3.

CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair open circuit.

4.

CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY CIRCUIT-III

Check harness for short to power and short to ground, between the following terminals.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair short to ground or short to power in harness or connectors.

5.

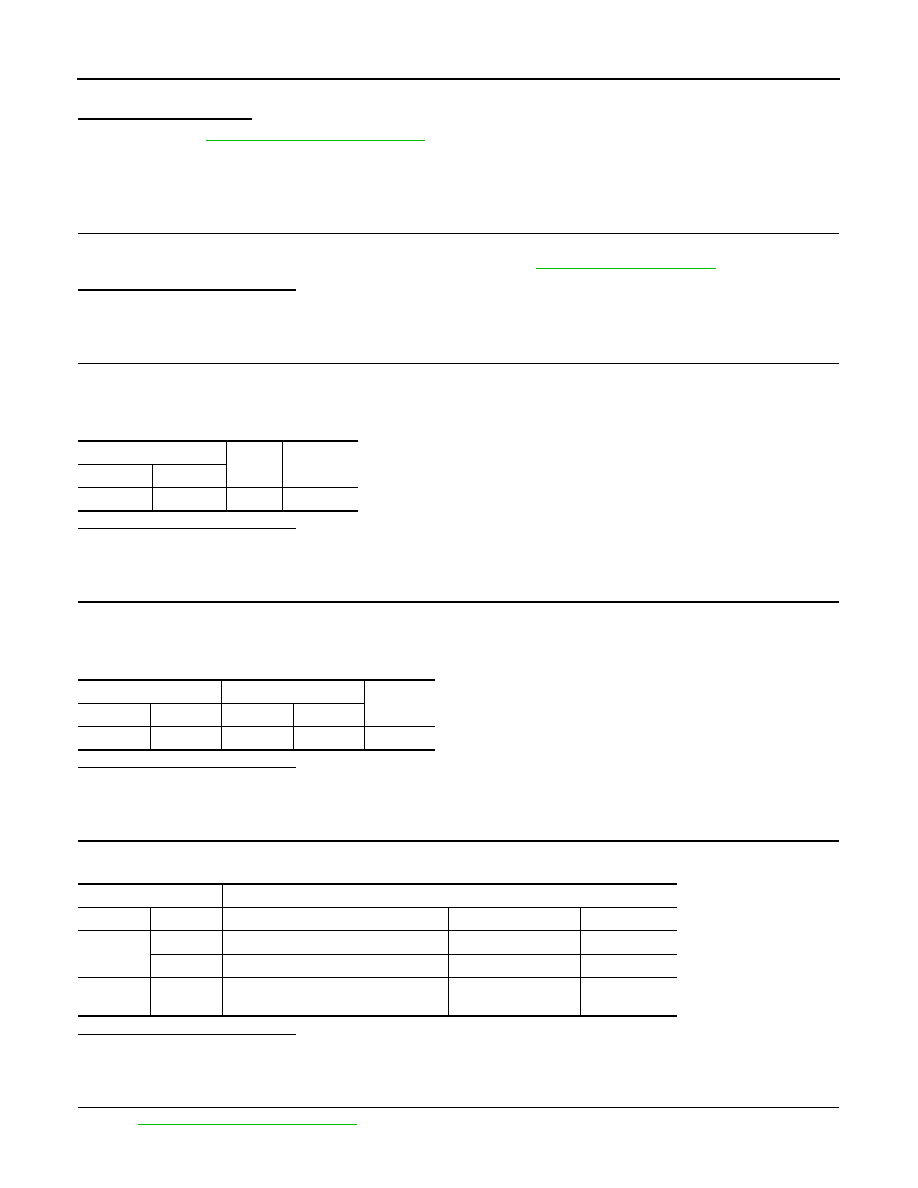

CHECK REFRIGERANT PRESSURE SENSOR

.

CKP sensor (POS)

Ground

Voltage

Connector

Terminal

F15

1

Ground

Approx. 5V

CKP sensor (POS)

ECM

Continuity

Connector

Terminal

Connector

Terminal

F15

1

F11

75

Existed

ECM

Sensor

Connector

Terminal

Name

Connector

Terminal

F11

74

Refrigerant pressure sensor

E17

3

75

CKP sensor (POS)

F15

1

E16

102

APP sensor 2

E12 (LHD models)

M204 (RHD models)

5