содержание .. 1409 1410 1411 1412 ..

Nissan Tiida C11. Manual - part 1411

TRANSAXLE ASSEMBLY

TM-695

< DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F94R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

4.

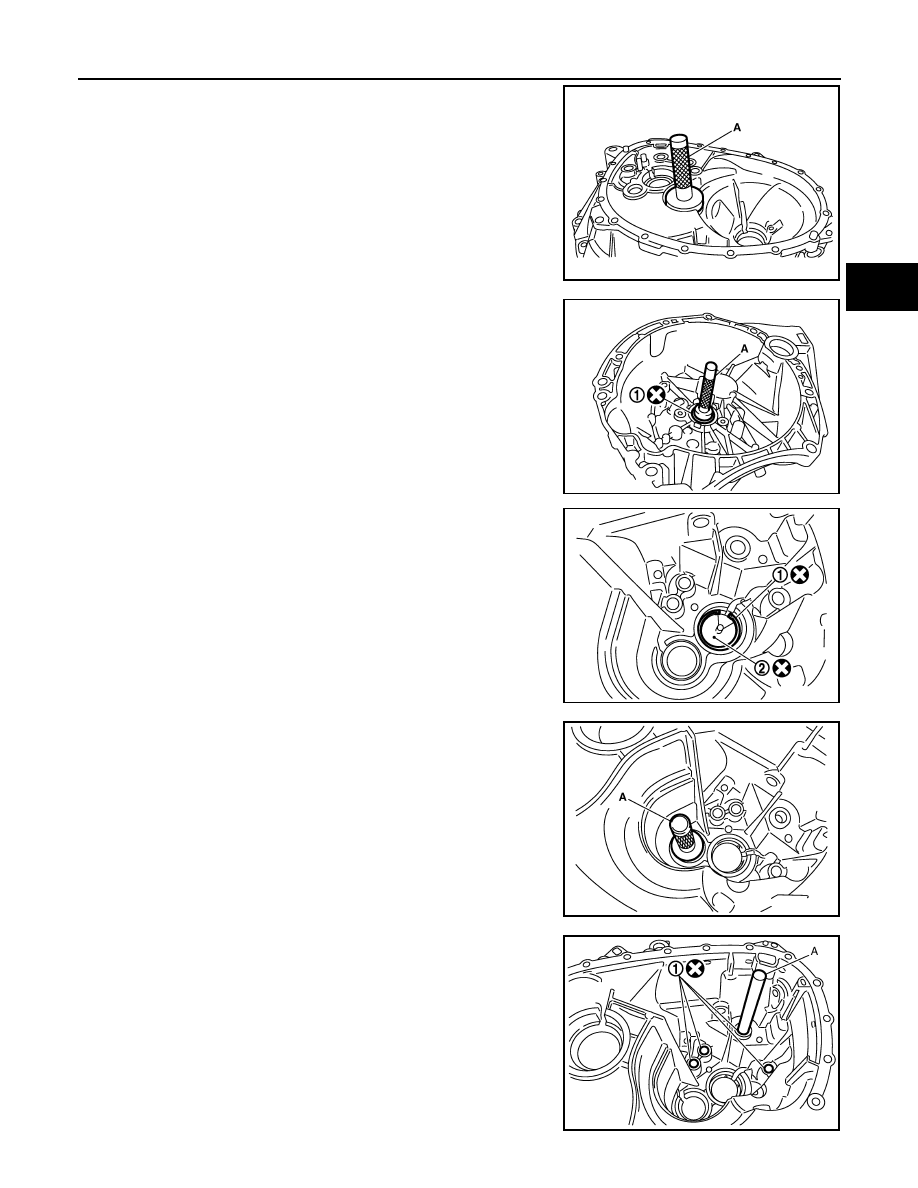

Install oil channel and mainshaft front bearing outer race into

clutch housing using Tool (A).

CAUTION:

• Do not reuse oil channel.

• Replace mainshaft front bearing outer race and mainshaft

front bearing inner race as a set.

5.

Install input shaft oil seal (1) into clutch housing using Tool (A).

6.

Install snap ring (1) and oil channel (2) onto transaxle case.

CAUTION:

Do not reuse snap ring or oil channel.

7.

Install bearing preloading shim and mainshaft rear bearing outer

race into transaxle case using Tool (A).

CAUTION:

Replace mainshaft rear bearing outer race and mainshaft

rear bearing inner race as a set.

8.

Install bushings (1) into transaxle case using suitable tool (A).

CAUTION:

Do not reuse bushings.

Tool number

: KV38100200 (

—

)

PCIB1724E

Tool number

: ST33220000 (

—

)

PCIB1721E

PCIB1729E

Tool number

: KV38100200 (

—

)

PCIB1728E

JPDIC0109ZZ