содержание .. 1312 1313 1314 1315 ..

Nissan Tiida C11. Manual - part 1314

ASSEMBLY

TM-307

< DISASSEMBLY AND ASSEMBLY >

[TYPE 1 (4AT: RE4F03B)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

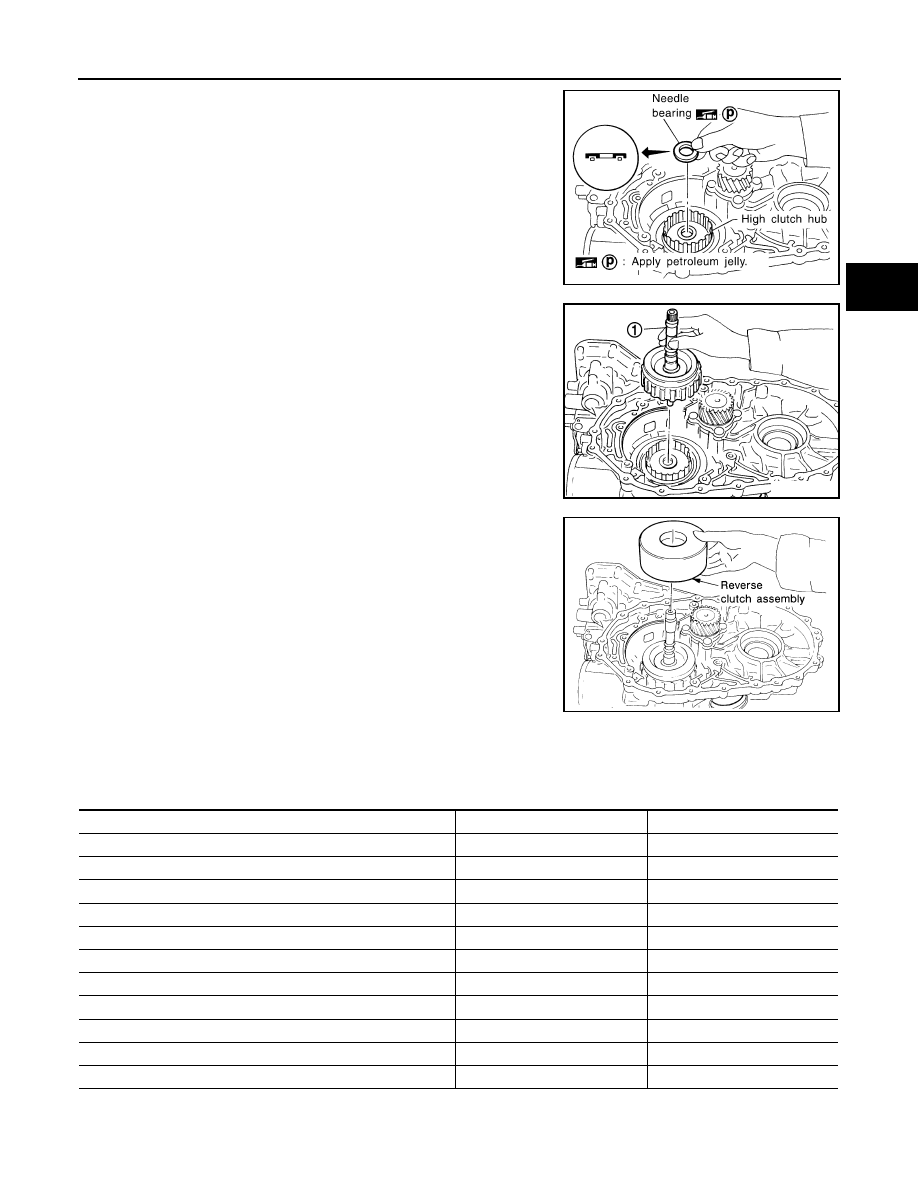

22. Install needle bearing on high clutch hub.

CAUTION:

Be careful with the direction of needle bearing.

23. Remove paper rolled around input shaft assembly (high clutch

drum).

24. Install input shaft assembly (high clutch assembly) (1).

CAUTION:

Align teeth of high clutch drive plates before installing.

25. Install reverse clutch assembly.

CAUTION:

Align teeth of reverse clutch drive plates before installing.

Adjustment (2)

INFOID:0000000001730999

When any parts listed below are replaced, adjust total end play and reverse clutch end play.

TOTAL END PLAY

SAT371D

SCIA7079E

SAT373D

Part name

Total end play

Reverse clutch end play

Transaxle case

●

●

Overrun clutch hub

●

●

Rear internal gear

●

●

Rear planetary carrier

●

●

Rear sun gear

●

●

Front planetary carrier

●

●

Front sun gear

●

●

High clutch hub

●

●

Input shaft assembly (high clutch drum)

●

●

Oil pump cover

●

●

Reverse clutch drum

—

●